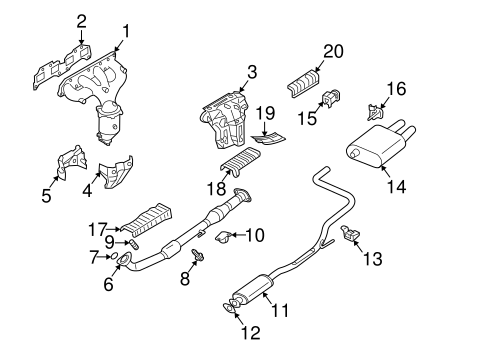

2005 Nissan Altima Exhaust Manifold

The 2005 Nissan Altima, a popular mid-size sedan, offered a blend of practicality and performance. A key component in achieving that performance is the exhaust manifold. This seemingly simple piece of metal plays a crucial role in the engine's ability to breathe efficiently. Let's delve into the details of the 2005 Altima's exhaust manifold, exploring its design, function, common problems, and potential solutions.

Understanding the Exhaust Manifold's Role

At its most basic, the exhaust manifold is responsible for collecting exhaust gases from the engine's cylinders and channeling them into the exhaust system. After combustion occurs within each cylinder, the resulting gases – containing substances like carbon dioxide, nitrogen, water vapor, and unburnt hydrocarbons – need to be efficiently expelled. The exhaust manifold is the first step in this process.

Its primary functions are:

- Collection: Gathering exhaust gases from each cylinder.

- Evacuation: Providing a pathway for these gases to exit the engine.

- Direction: Channeling the gases towards the catalytic converter and subsequent exhaust components.

The efficiency of the exhaust manifold directly impacts the engine's performance. A well-designed manifold minimizes backpressure, allowing the engine to breathe more freely, which can translate to increased horsepower and torque. Conversely, a poorly designed manifold can restrict exhaust flow, leading to reduced performance and even engine damage.

The 2005 Altima's Exhaust Manifold Design

The 2005 Altima came with two primary engine options: a 2.5-liter inline-4 (QR25DE) and a 3.5-liter V6 (VQ35DE). Each engine utilized a different exhaust manifold configuration. We'll focus on the more common 2.5L I4 engine for this analysis.

The QR25DE engine features a 4-into-1 exhaust manifold design. This means that each of the four cylinders has its own individual exhaust runner that connects to a single collector. This design is common in inline engines due to its relative simplicity and cost-effectiveness.

Key design characteristics of the 2005 Altima 2.5L exhaust manifold include:

- Material: The original equipment manufacturer (OEM) manifold is typically made from cast iron. Cast iron is chosen for its durability, heat resistance, and relatively low cost. It can withstand the extreme temperatures of exhaust gases without significant degradation.

- Runner Length: The length of the individual runners plays a crucial role in exhaust tuning. While the exact dimensions are proprietary, the design likely aimed for a balance between low-end torque and high-end horsepower. Generally, longer runners can enhance low-end torque by promoting scavenging effects, while shorter runners favor high-rpm power.

- Collector Design: The collector is where all the individual runners merge. Its design influences the flow characteristics of the exhaust gases. A smooth, gradual transition from the individual runners to the collector helps to minimize turbulence and backpressure.

- Catalytic Converter Integration: In the 2005 Altima, the catalytic converter is often integrated directly into the exhaust manifold. This design allows for quicker converter warm-up, which is important for reducing emissions. However, it also means that if the catalytic converter fails, the entire manifold assembly typically needs to be replaced. This is a significant consideration for maintenance and repair.

The VQ35DE engine in the Altima features a more complex exhaust manifold design due to the V6 configuration. It has two separate exhaust manifolds, one for each bank of cylinders. These manifolds are typically shorter and more compact than the inline-4 manifold. The principles of runner length and collector design still apply, but the overall configuration is dictated by the engine's physical layout.

Aftermarket Options

It's important to note that aftermarket exhaust manifolds are available for the 2005 Altima. These manifolds often feature different designs and materials than the OEM manifold. Stainless steel is a common alternative to cast iron, offering improved corrosion resistance and potentially lighter weight. Aftermarket manifolds may also incorporate different runner lengths and collector designs to optimize performance for specific driving styles or modifications. However, it's crucial to ensure that any aftermarket manifold complies with local emissions regulations.

Common Problems and Diagnosis

The exhaust manifold is subjected to extreme temperatures and stresses, making it susceptible to certain problems over time. Here are some of the most common issues:

- Cracking: Repeated heating and cooling cycles can cause the cast iron manifold to crack. Cracks can lead to exhaust leaks, which can reduce engine performance, increase emissions, and create a characteristic hissing or ticking noise.

- Warping: Similar to cracking, warping can occur due to thermal stress. A warped manifold may not seal properly against the cylinder head, resulting in exhaust leaks.

- Catalytic Converter Failure: As mentioned earlier, the integrated catalytic converter is a potential point of failure. Over time, the catalyst material can degrade, reducing its ability to convert harmful emissions. Symptoms of a failing catalytic converter include reduced engine performance, poor fuel economy, and a "rotten egg" smell from the exhaust. A check engine light with diagnostic trouble codes (DTCs) related to catalyst efficiency is a strong indicator of this issue.

- Exhaust Leaks: Leaks can occur at the manifold gasket (where the manifold bolts to the cylinder head) or at the flange where the manifold connects to the rest of the exhaust system. Leaks at the gasket are often caused by deteriorated gasket material or loose bolts.

- Broken Studs: The bolts or studs that secure the manifold to the cylinder head can sometimes break, especially when attempting to remove a corroded manifold. This can make manifold replacement more difficult.

Diagnosis: Identifying exhaust manifold problems typically involves a visual inspection, listening for exhaust leaks, and checking for relevant DTCs with an OBD-II scanner. A mechanic can use a smoke machine to detect leaks by introducing smoke into the exhaust system and observing where it escapes. Listening carefully around the manifold with the engine running can also help pinpoint the source of a leak.

Repair and Replacement

Repairing a cracked or warped exhaust manifold is generally not recommended. Welding a cast iron manifold can be challenging and may not provide a long-lasting solution. The best course of action is usually to replace the entire manifold assembly.

Replacement Procedure (General):

- Safety First: Allow the engine to cool completely before starting any work. Disconnect the negative battery cable to prevent electrical accidents.

- Access: Depending on the vehicle, you may need to remove other components to access the exhaust manifold.

- Disconnect Sensors and Components: Carefully disconnect any sensors or components attached to the manifold, such as oxygen sensors.

- Loosen Bolts: Apply penetrating oil to the manifold bolts or studs to help loosen them. Be patient and use appropriate tools to avoid breaking the bolts. If a bolt breaks, it may need to be extracted, which can be a challenging process.

- Remove Manifold: Once all bolts are removed, carefully remove the old exhaust manifold.

- Clean Surfaces: Thoroughly clean the mating surfaces on the cylinder head. Remove any old gasket material.

- Install New Gasket: Install a new exhaust manifold gasket.

- Install New Manifold: Carefully install the new exhaust manifold, ensuring it aligns properly with the cylinder head.

- Tighten Bolts: Tighten the manifold bolts to the manufacturer's specified torque in the correct sequence. This ensures even pressure distribution and a proper seal.

- Reconnect Components: Reconnect any sensors or components that were disconnected.

- Final Checks: Double-check all connections and ensure that everything is properly installed.

- Start Engine: Start the engine and listen for any exhaust leaks. Monitor for any unusual noises or vibrations.

Important Note: Replacing an exhaust manifold, especially one with an integrated catalytic converter, can be a complex and potentially challenging task. If you are not comfortable performing this repair yourself, it is best to seek the assistance of a qualified mechanic.

Conclusion

The exhaust manifold on the 2005 Nissan Altima is a critical component that plays a significant role in engine performance and emissions control. Understanding its design, function, and common problems can help owners diagnose issues and make informed decisions about repair and replacement. While the OEM cast iron manifold provides durability, aftermarket options may offer improved performance characteristics. Regular inspection and maintenance of the exhaust system can help prevent costly repairs and ensure optimal engine operation.