2006 Nissan Maxima Transmission Problems

The 2006 Nissan Maxima, a member of the sixth generation (A34), is generally a comfortable and stylish sedan. However, like many vehicles, it's not without its potential problems. One of the more significant concerns that owners have reported revolves around the automatic transmission, specifically the RE5F22A five-speed automatic. This article delves into common transmission issues encountered in the 2006 Maxima, providing insights into diagnostics, potential causes, and possible solutions for the experienced DIYer.

Common Transmission Problems in the 2006 Nissan Maxima

Several recurring issues plague the RE5F22A transmission in the 2006 Maxima. Understanding these problems is the first step in diagnosing and resolving them.

Slipping Gears

Gear slippage is a frequent complaint. This manifests as the engine revving excessively without a corresponding increase in vehicle speed. It often occurs during acceleration or when shifting between gears. This can be caused by several factors, including:

- Low Transmission Fluid Level: The most basic, but often overlooked cause. Low fluid reduces hydraulic pressure, preventing proper clutch engagement.

- Worn Clutch Packs: Inside the transmission are clutch packs that engage and disengage to switch gears. Over time, these friction materials wear down, leading to slippage. A transmission fluid analysis can often indicate the presence of friction material in the fluid.

- Faulty Solenoids: Solenoids are electro-hydraulic valves that control the flow of transmission fluid to different parts of the transmission, directing pressure to engage the correct gears. A malfunctioning solenoid can prevent proper gear engagement. These can sometimes be tested using a multimeter to check resistance.

- Valve Body Issues: The valve body is the hydraulic control center of the transmission. It contains channels and valves that regulate fluid flow. Wear and tear, debris, or stuck valves can disrupt the hydraulic pressure needed for proper gear engagement. This is a more complex issue often requiring professional diagnosis.

Rough Shifting

Harsh or jerky shifts, especially between certain gears, are another common symptom. This can feel like a distinct "thump" or "jerk" during acceleration or deceleration. Potential causes include:

- Dirty or Degraded Transmission Fluid: Over time, transmission fluid loses its lubricating properties and can become contaminated with debris. This can affect valve body operation and clutch engagement, leading to rough shifting. Regular fluid changes are crucial.

- Faulty Shift Solenoids: Similar to slippage, malfunctioning solenoids can cause abrupt and harsh shifts.

- Torque Converter Problems: The torque converter acts as a fluid coupling between the engine and transmission. If the torque converter is failing, it can cause vibrations and rough shifting, particularly at low speeds. A stall test (performed with caution and proper safety measures) can help diagnose torque converter issues.

- Internal Mechanical Damage: In severe cases, damaged gears or other internal components can cause rough shifting. This often necessitates a transmission rebuild or replacement.

Delayed Engagement

This occurs when there's a noticeable delay between shifting into Drive (D) or Reverse (R) and the vehicle actually moving. A healthy transmission should engage almost immediately. Possible causes are:

- Low Transmission Fluid Level: Again, this is a prime suspect. Insufficient fluid hinders the transmission's ability to build pressure and engage gears quickly.

- Worn Transmission Pump: The transmission pump is responsible for generating hydraulic pressure. A worn pump may not be able to produce sufficient pressure to engage the gears promptly. Pressure testing the transmission lines is necessary to diagnose this.

- Internal Leaks: Leaks within the transmission can reduce hydraulic pressure, leading to delayed engagement. These leaks may be difficult to detect without dismantling the transmission.

Transmission Overheating

While not as frequent as the other issues, overheating can significantly damage the transmission. Symptoms include a burning smell, difficulty shifting, and eventually, complete transmission failure. Causes include:

- Low Transmission Fluid: Low fluid reduces the transmission's ability to dissipate heat effectively.

- Clogged Transmission Cooler: The transmission cooler is a small radiator that helps regulate transmission fluid temperature. A clogged cooler restricts fluid flow, leading to overheating.

- Excessive Load or Towing: Exceeding the vehicle's towing capacity or subjecting it to prolonged heavy loads can generate excessive heat within the transmission.

Check Engine Light (CEL) with Transmission Codes

The presence of a Check Engine Light (CEL) is a crucial indicator of a problem. Using an OBD-II scanner, you can retrieve Diagnostic Trouble Codes (DTCs) that relate to the transmission. Common codes include:

- P07XX Codes: These codes generally indicate problems with shift solenoids or transmission range sensors. Examples include P0740 (Torque Converter Clutch Circuit Malfunction), P0750 (Shift Solenoid A Malfunction), and P0775 (Pressure Control Solenoid B Malfunction).

- P08XX Codes: Often point to issues within the transmission control module (TCM) or communication problems between the TCM and other vehicle systems.

- P17XX Codes: These are Nissan-specific codes that can pinpoint specific transmission problems, such as slippage in a particular gear or issues with the torque converter clutch.

It's crucial to diagnose the root cause of the code before simply replacing parts. A code only indicates a symptom, not necessarily the problem itself.

Diagnosis and Troubleshooting

A systematic approach to diagnosis is essential for resolving transmission problems. Here's a general troubleshooting process:

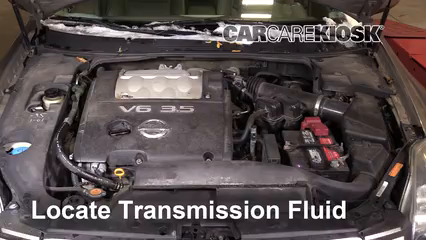

- Check Transmission Fluid Level and Condition: Use the dipstick (usually located under the hood and marked for transmission fluid) to check the fluid level. The fluid should be red and translucent, not dark brown or black, and it should not smell burnt. If the fluid is low, add the correct type (typically Nissan Matic S). If it's dirty or burnt, a fluid change is recommended.

- OBD-II Scan: Use an OBD-II scanner to retrieve any DTCs stored in the vehicle's computer. Research the codes thoroughly to understand their potential causes.

- Visual Inspection: Inspect the transmission for any external leaks. Check the transmission cooler lines and radiator for signs of damage or corrosion.

- Solenoid Testing: If you suspect a solenoid issue, you can use a multimeter to check its resistance. Consult the vehicle's service manual for the correct resistance values. You can also sometimes energize the solenoid directly with a low-voltage power source to see if it clicks, indicating proper operation (again, consult the service manual for safe voltage levels).

- Valve Body Inspection (Advanced): This is a more advanced procedure. Removing and inspecting the valve body requires careful attention to detail and cleanliness. Look for stuck valves, worn passages, and debris. This is often best left to a professional.

- Pressure Testing (Advanced): Using a specialized pressure gauge, you can measure the hydraulic pressure at various points within the transmission. This can help identify problems with the transmission pump, valve body, or internal leaks. Requires specialized tools and knowledge.

Potential Solutions

Based on your diagnosis, here are some potential solutions:

- Transmission Fluid Change: A simple fluid change can often resolve minor issues like rough shifting caused by dirty fluid. Use only the recommended Nissan Matic S fluid.

- Solenoid Replacement: If a solenoid is faulty, replacing it can often resolve slippage or rough shifting problems.

- Valve Body Repair or Replacement: A damaged or worn valve body can be rebuilt or replaced. This is a more complex repair that may be best left to a professional.

- Transmission Cooler Flush or Replacement: A clogged transmission cooler can be flushed to remove debris. If it's damaged or corroded, it should be replaced.

- Transmission Rebuild or Replacement: In cases of severe internal damage, a transmission rebuild or replacement may be necessary. This is the most expensive option but may be the only solution for major problems.

- Torque Converter Replacement: If the torque converter is failing, replacing it will restore smooth power transfer between the engine and transmission.

Important Considerations

- Use the Correct Transmission Fluid: Using the wrong type of transmission fluid can cause serious damage. Always use Nissan Matic S fluid for the RE5F22A transmission.

- Cleanliness is Crucial: When working on the transmission, maintain a clean work environment. Debris can easily contaminate the transmission and cause further problems.

- Consult a Service Manual: A detailed service manual for the 2006 Nissan Maxima is invaluable for diagnosing and repairing transmission problems. It provides detailed instructions, diagrams, and specifications.

- Safety First: Always take proper safety precautions when working on your vehicle. Use jack stands to support the vehicle, wear safety glasses, and disconnect the battery before working on electrical components.

- Know Your Limits: Transmission repair can be complex. If you're not comfortable performing a particular task, seek the help of a qualified mechanic. It's better to pay for professional help than to cause further damage.

By understanding the common problems, following a systematic diagnostic process, and taking the necessary precautions, you can successfully troubleshoot and resolve many transmission issues in your 2006 Nissan Maxima. However, always remember that complex repairs are best left to qualified professionals to ensure the longevity and reliability of your vehicle.