2006 Nissan Titan Driver Seat Replacement

Replacing a driver's seat might seem like a straightforward unbolt-and-replace affair, but modern vehicles, especially those with powered and heated seats like the 2006 Nissan Titan, involve more complexities. This technical guide provides an in-depth look at the process, highlighting the electrical systems, mechanical considerations, and potential pitfalls you might encounter when swapping the driver's seat in this robust pickup truck.

Safety First: Disconnecting the Battery

Before you even think about touching a wrench, disconnect the negative terminal of your battery. This is absolutely crucial. Modern vehicles are riddled with sensitive electronics, and accidentally shorting something during the seat removal process can cause significant damage, potentially frying modules and triggering airbag deployment. The negative terminal is usually indicated with a minus (-) sign. Use a wrench (typically 10mm) to loosen the nut and carefully detach the cable. Tuck the cable away so it cannot accidentally reconnect during the process. Wait at least 15 minutes after disconnecting the battery before proceeding. This allows any residual charge in the system to dissipate, further reducing the risk of airbag deployment.

Tools and Materials: What You'll Need

Having the right tools will make this job significantly easier and safer. Here's a comprehensive list:

- Socket set (metric): This is essential for removing the seat bolts and potentially other components. A good range of sizes is recommended.

- Wrench set (metric): Similar to the socket set, having a range of wrench sizes on hand will prove useful.

- Torx bit set: Some Nissan vehicles use Torx head screws, so having a set of these is important.

- Screwdriver set (Phillips and flathead): Various sizes will come in handy for removing trim pieces and accessing connectors.

- Pliers: For gripping and manipulating connectors and wires.

- Wire strippers/crimpers: If you need to repair or modify any wiring, these are essential.

- Multimeter: For testing electrical circuits and ensuring proper connections.

- Protective gloves: To protect your hands from sharp edges and potential contaminants.

- Pen and paper or a digital camera: To document the location and connection of wires and connectors. This is especially critical when dealing with multiple electrical connections.

- Shop towels or rags: For cleaning and wiping up any spills.

- Penetrating oil: For loosening stubborn bolts or screws.

- Floor jack and jack stands (optional, but recommended): If you need more clearance to access bolts under the seat.

Removing the Original Seat: A Step-by-Step Guide

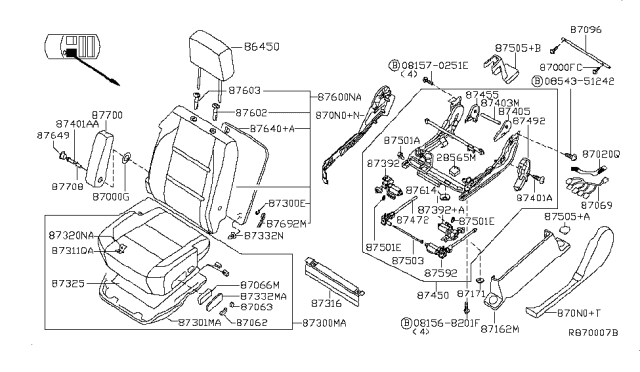

Step 1: Locating and Removing the Seat Bolts

The driver's seat is typically secured by four bolts located at the corners of the seat frame, attaching it to the floor of the vehicle. These are usually accessible from inside the vehicle, but sometimes plastic trim covers them. Pry off any trim pieces carefully using a flathead screwdriver or a trim removal tool. Once the bolts are exposed, use the appropriate socket size to loosen and remove them. If the bolts are rusted or corroded, apply penetrating oil and let it soak for a few minutes before attempting to remove them. Be careful not to strip the bolt heads; if they're too difficult to remove, consider using a bolt extractor.

Step 2: Disconnecting the Electrical Connectors

This is where things get a bit more involved. The driver's seat in a 2006 Nissan Titan likely has multiple electrical connectors for power adjustments, seat heaters, and potentially seatbelt pretensioners or side airbags. Before disconnecting anything, thoroughly document the location and function of each connector. Take pictures or draw a diagram. This will save you a lot of headaches when you're reconnecting everything. Disconnect each connector carefully, pressing the release tabs and gently pulling them apart. Never force a connector; if it doesn't come apart easily, double-check that you've pressed the release tab correctly. Pay close attention to the airbag connector, as mishandling it can lead to accidental airbag deployment. Follow proper procedures (wait 15 minutes after battery disconnect!) and handle it with care.

If you are dealing with a corroded or damaged connector, now would be a good time to repair or replace it. Clean any corrosion with electrical contact cleaner and use a wire brush if necessary. If the connector is severely damaged, you may need to splice in a new connector using wire strippers, crimpers, and appropriate connectors. Make sure to use high-quality connectors and ensure a secure connection to prevent future problems.

Step 3: Removing the Seat from the Vehicle

With the bolts removed and the electrical connectors disconnected, you can now carefully remove the seat from the vehicle. Be mindful of the door sill and any other interior trim pieces to avoid scratches or damage. Tilting the seat back can sometimes make it easier to maneuver it out of the vehicle. If the seat is heavy, get help from a friend to avoid straining your back. Once the seat is out, place it on a clean surface to prevent damage.

Installing the Replacement Seat: Reversing the Process

Installing the replacement seat is essentially the reverse of the removal process, but here are some key points to keep in mind:

Step 1: Preparing the Replacement Seat

Before installing the replacement seat, inspect it thoroughly for any damage or defects. Check the seat frame, upholstery, and electrical components. Make sure all the necessary hardware is included. If the replacement seat is used, clean it thoroughly before installing it in the vehicle.

Step 2: Connecting the Electrical Connectors

Using your documentation from the removal process, carefully reconnect all the electrical connectors to the replacement seat. Ensure that each connector is securely connected and that the release tabs are engaged. Double-check your work to avoid any wiring errors.

Step 3: Securing the Seat to the Vehicle

Position the replacement seat in the vehicle and align it with the mounting holes. Install the seat bolts and tighten them to the manufacturer's specified torque. Use a torque wrench to ensure proper tightening. Overtightening the bolts can damage the seat frame or the floor of the vehicle. Once the bolts are tightened, reinstall any trim pieces that were removed.

Testing and Troubleshooting

After installing the replacement seat, reconnect the negative terminal of the battery. Start the vehicle and test all the seat functions, including power adjustments, seat heaters, and any other features. If any of the functions are not working properly, check the electrical connectors and wiring for any loose connections or damage. Use a multimeter to test the circuits and identify any problems.

One common issue after replacing a seat is the airbag warning light illuminating on the dashboard. This can be caused by a faulty airbag sensor, a loose connection, or a problem with the airbag control module. If the airbag warning light is on, it's important to have the system diagnosed by a qualified technician. Do not attempt to diagnose or repair the airbag system yourself, as this can be dangerous.

If the seat is not adjusting properly, check the seat tracks for any obstructions. Make sure the seat tracks are properly lubricated to ensure smooth operation. If the seat heaters are not working, check the heating element and the thermostat. Use a multimeter to test the circuits and identify any problems.

Potential Pitfalls and Considerations

- Airbag Deployment: As mentioned earlier, the airbag system is extremely sensitive, and improper handling can lead to accidental deployment. Always disconnect the battery and wait at least 15 minutes before working on any electrical components related to the airbags.

- Seatbelt Pretensioners: Some seats have seatbelt pretensioners, which are pyrotechnic devices that tighten the seatbelt in the event of a collision. These devices are also sensitive and should be handled with care.

- Wiring Issues: If you encounter any damaged or corroded wiring, repair it properly using high-quality connectors and wiring. Ensure that all connections are secure and properly insulated.

- Torque Specifications: Always tighten the seat bolts to the manufacturer's specified torque. Overtightening can damage the seat frame or the floor of the vehicle.

- Aftermarket Seats: If you are installing an aftermarket seat, make sure it is compatible with your vehicle. You may need to purchase an adapter to connect the seat to the vehicle's electrical system.

Conclusion

Replacing the driver's seat in a 2006 Nissan Titan is a task that can be accomplished by a mechanically inclined individual with the right tools and knowledge. However, it's crucial to prioritize safety, especially when dealing with the electrical system and airbag components. By following this detailed guide and taking the necessary precautions, you can successfully replace your driver's seat and enjoy a more comfortable and supportive driving experience. Remember, if you are not comfortable performing this task yourself, it's always best to seek the assistance of a qualified technician.