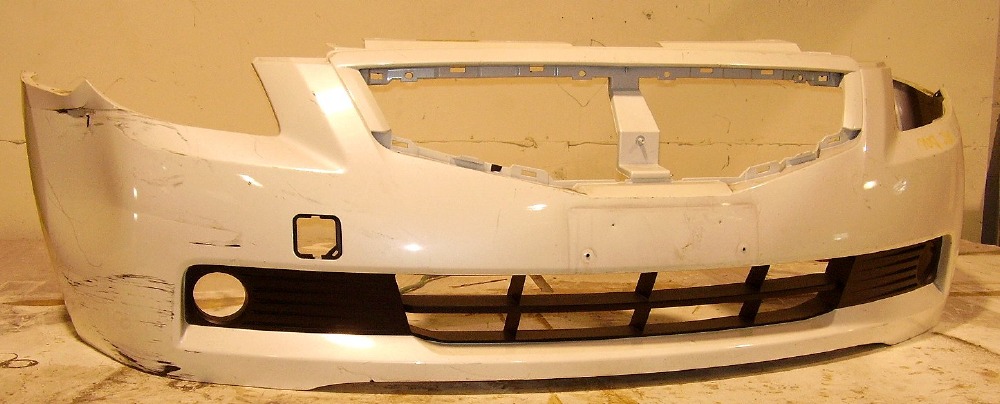

2008 Nissan Altima Coupe Front Bumper

The 2008 Nissan Altima Coupe's front bumper isn't just a cosmetic piece; it's a carefully engineered system designed to protect vehicle occupants and pedestrians, manage airflow, and contribute to the overall aesthetic of the car. This in-depth look dissects the components, materials, and design considerations that went into creating this seemingly simple part.

Bumper System Components

The term "bumper" is often used to describe the entire front-end assembly, but it's actually composed of several distinct components that work together. Understanding these components is key to appreciating the bumper's overall functionality.

Bumper Cover

The bumper cover is the painted, exterior shell that most people identify as the bumper. It's primarily an aesthetic component, but it also plays a crucial role in aerodynamics and pedestrian safety. On the 2008 Altima Coupe, the bumper cover is made of polypropylene (PP) plastic. This material was chosen for its balance of flexibility, impact resistance, and cost-effectiveness. PP allows the bumper to deform and absorb energy during low-speed impacts, minimizing damage to the vehicle's structure and occupants. The cover is typically painted to match the vehicle's body color and is designed with various contours and features to integrate with the headlights, grille, and overall vehicle design.

The manufacturing process for the bumper cover usually involves injection molding. Molten PP is injected into a mold under high pressure, creating the desired shape. After cooling, the cover is removed, trimmed, and prepared for painting. The thickness of the PP material varies depending on the area of the bumper, with thicker sections providing greater impact resistance in critical zones.

Bumper Reinforcement Bar

Behind the bumper cover lies the bumper reinforcement bar, also known as the bumper beam. This is the primary energy-absorbing component of the bumper system. On the 2008 Altima Coupe, the reinforcement bar is typically made of high-strength steel. Some manufacturers might use aluminum for weight reduction, but steel's superior strength and cost-effectiveness make it a common choice. The reinforcement bar is strategically positioned to withstand impacts and distribute the force across the vehicle's frame.

The reinforcement bar's cross-sectional shape is also crucial. It's often designed with a hat-shaped or C-shaped profile to maximize its resistance to bending and buckling. The design must account for offset impacts as well as direct impacts. The reinforcement bar is mounted to the vehicle's frame rails via brackets designed to crumple in a controlled manner during an impact, further absorbing energy. The mounting points are also carefully chosen to ensure that the impact forces are effectively transferred to the vehicle's structural members.

Energy Absorbers

Located between the bumper cover and the reinforcement bar are the energy absorbers. These components are designed to cushion the impact and reduce the severity of the collision, particularly in low-speed impacts. The energy absorbers on the 2008 Altima Coupe are often made of expanded polypropylene (EPP) foam or a similar deformable material. EPP is lightweight, highly compressible, and provides excellent energy absorption.

The design of the energy absorbers is critical. They are often molded with specific shapes and features to control their deformation behavior. For example, they might have crush zones or ribs that collapse in a predictable manner, allowing them to absorb energy effectively over a range of impact speeds. The positioning and size of the energy absorbers are also carefully calculated to optimize their performance. Their effectiveness is directly related to the geometry and material properties.

Mounting Brackets

The entire bumper system is secured to the vehicle's frame using a series of mounting brackets. These brackets are typically made of steel and are designed to withstand the forces generated during an impact. The brackets are carefully positioned and designed to ensure that the bumper is securely attached to the vehicle and that the impact forces are properly distributed. They often incorporate breakaway features, designed to fail in a controlled manner during a severe impact, preventing damage to the vehicle's frame rails. These brackets are usually bolted to both the reinforcement bar and the frame.

Design Considerations

The design of the 2008 Nissan Altima Coupe's front bumper involves a complex interplay of factors, including safety regulations, aerodynamic performance, manufacturing feasibility, and aesthetic appeal.

Safety Regulations

Bumper design is heavily influenced by government regulations designed to protect both vehicle occupants and pedestrians. Regulations like those from the Insurance Institute for Highway Safety (IIHS) and the National Highway Traffic Safety Administration (NHTSA) set standards for bumper performance in low-speed impacts. These standards specify the amount of damage that is allowed to the vehicle's components in a series of controlled crash tests. The 2008 Altima Coupe's bumper was engineered to meet or exceed these standards. These tests include pendulum impacts, corner impacts, and full-width barrier impacts.

Pedestrian Safety

In recent years, pedestrian safety has become an increasingly important consideration in bumper design. Modern bumpers are designed to minimize the severity of injuries to pedestrians in the event of a collision. This is achieved by incorporating features such as:

- Energy-absorbing materials: The bumper cover and energy absorbers are designed to deform and cushion the impact, reducing the risk of serious injuries to the legs and head.

- Rounded edges: The bumper's edges are often rounded to reduce the risk of fractures and other injuries.

- Reduced stiffness: The bumper is designed to be relatively flexible, allowing it to deform and distribute the impact force over a wider area.

Aerodynamics

The front bumper also plays a significant role in the vehicle's aerodynamic performance. The shape of the bumper is designed to reduce drag and improve fuel efficiency. Features like the air dam (the lower portion of the bumper) help to deflect air around the vehicle, reducing turbulence and drag. The bumper is also designed to channel air to the radiator and other engine components, improving cooling performance. Computer simulations and wind tunnel testing are used extensively to optimize the bumper's aerodynamic properties.

Manufacturing and Assembly

The bumper's design must also be compatible with the constraints of manufacturing and assembly. The bumper cover, reinforcement bar, and energy absorbers must be designed for efficient and cost-effective production. The assembly process must be straightforward and reliable. This often involves optimizing the shapes and sizes of the components to minimize material waste and streamline the manufacturing process. The use of modular designs also simplifies the assembly process and allows for variations in the bumper's features. Injection molding is the key process for producing the cover, and steel forming is for the reinforcement bar.

Material Selection

The choice of materials for the bumper components is critical to its performance. As mentioned earlier, polypropylene (PP) is commonly used for the bumper cover due to its flexibility, impact resistance, and cost-effectiveness. High-strength steel is often used for the reinforcement bar due to its strength and ability to absorb energy. Expanded polypropylene (EPP) foam is a popular choice for energy absorbers due to its lightweight and excellent energy-absorbing properties. Each material is selected based on its specific properties and how it contributes to the overall performance of the bumper system.

Advancements in materials science are continually leading to the development of new and improved bumper materials. For example, some manufacturers are exploring the use of fiber-reinforced composites for the bumper cover and reinforcement bar. These materials offer a combination of high strength, lightweight, and excellent impact resistance.

Conclusion

The 2008 Nissan Altima Coupe's front bumper is a testament to the complexities of automotive engineering. It's more than just a decorative panel; it's a carefully engineered system designed to protect occupants and pedestrians, manage airflow, and contribute to the overall aesthetic of the car. From the material selection to the structural design, every aspect of the bumper is optimized for performance, safety, and manufacturing efficiency. Understanding the components and design considerations involved in creating this seemingly simple part provides a deeper appreciation for the engineering that goes into modern automobiles.