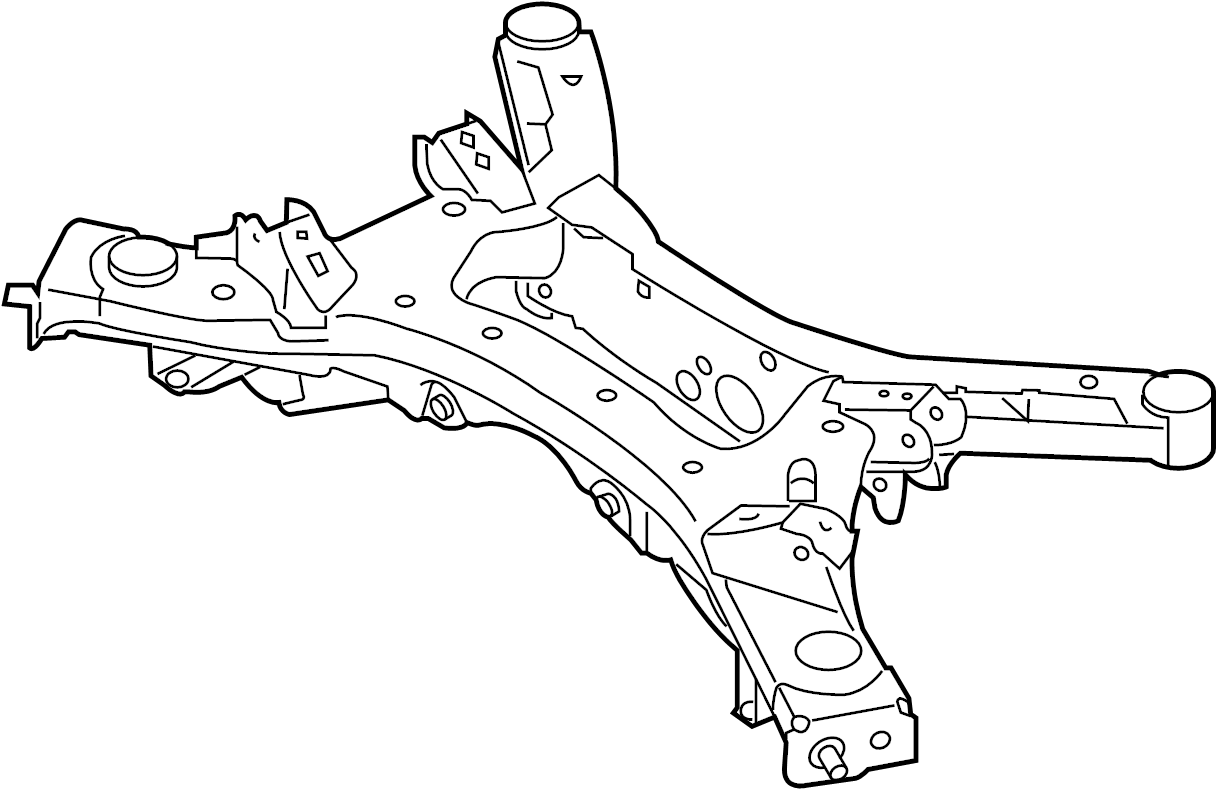

2009 Nissan Murano Awd Rear Subframe

The 2009 Nissan Murano, a vehicle celebrated for its blend of comfort and practicality, employs a sophisticated all-wheel-drive (AWD) system. At the heart of the rear suspension and AWD functionality lies the rear subframe, a critical component often overlooked. This article delves into the intricacies of the 2009 Murano AWD rear subframe, exploring its design, function, materials, common issues, and its impact on the vehicle's overall performance.

Function and Purpose

The rear subframe, also known as a rear suspension cradle, serves as a mounting point for several crucial components. It's essentially a structural framework that allows for the independent movement and controlled articulation of the rear suspension system. Its primary functions include:

- Providing a rigid mounting platform: The subframe securely houses the rear differential, rear suspension control arms (both upper and lower), wheel hubs/bearings, and often the rear sway bar. This centralized mounting prevents these components from being directly attached to the vehicle's body, isolating road noise and vibrations.

- Isolating noise and vibration: By acting as an intermediary between the suspension and the chassis, the subframe significantly reduces the transmission of road noise, vibrations, and harshness (NVH) into the passenger cabin. Rubber bushings are strategically placed at the subframe's mounting points to the vehicle body, further dampening vibrations.

- Enhancing handling and stability: The subframe's design contributes significantly to the vehicle's handling characteristics. By precisely positioning the suspension components, it helps maintain proper wheel alignment and control body roll during cornering. The rigidity of the subframe is crucial for ensuring predictable and responsive handling.

- Supporting the AWD system: In the 2009 Murano AWD, the rear differential, which distributes power to the rear wheels, is directly mounted to the subframe. This integration is essential for the seamless operation of the AWD system.

- Providing structural support in collisions: The subframe contributes to the vehicle's overall crashworthiness. It's designed to absorb and distribute impact forces during a collision, helping to protect the occupants.

Design and Construction

The 2009 Murano's rear subframe is typically constructed from stamped and welded steel. The specific design is a unibody design consisting of a boxed frame structure with strategically placed gussets to enhance strength and rigidity. The manufacturing process typically involves:

- Stamping: Large sheets of steel are stamped into the desired shapes for the various subframe components.

- Welding: The stamped components are then robotically welded together to form the complete subframe assembly. The welds are critical for ensuring the structural integrity of the subframe.

- Machining: After welding, some areas of the subframe may be machined to ensure precise tolerances for component mounting.

- Coating: The subframe is then coated with a rust-resistant material, typically a black paint or powder coating, to protect it from corrosion.

The subframe's design incorporates several key features:

- Mounting Points: Precisely located mounting points for the rear differential, suspension control arms, wheel hubs, and sway bar. These mounting points are designed to withstand significant loads and forces.

- Bushings: Rubber bushings are strategically placed at the subframe's mounting points to the vehicle's body. These bushings absorb vibrations and reduce noise transmission. Different bushing durometers (hardness) may be used at different mounting points to optimize NVH characteristics.

- Reinforcements: Gussets and reinforcements are added to high-stress areas of the subframe to enhance its strength and rigidity. These reinforcements help prevent bending and twisting under load.

- Geometry: The overall geometry of the subframe is carefully designed to optimize suspension performance and handling characteristics. The angles and positions of the mounting points are critical for achieving the desired suspension geometry.

Materials

The material selection for the rear subframe is crucial for its strength, durability, and weight. While specific grades may vary, the following materials are commonly used:

- High-Strength Steel: The primary material is typically high-strength, low-alloy (HSLA) steel. This type of steel offers a good balance of strength, weldability, and cost.

- Rubber Bushings: Natural or synthetic rubber compounds are used for the bushings. The specific rubber compound is chosen based on its damping characteristics, durability, and resistance to environmental factors.

- Coatings: Protective coatings, such as electrodeposition coatings (e-coat) or powder coatings, are applied to prevent corrosion. These coatings provide a barrier against moisture, salt, and other corrosive elements.

Common Issues and Failure Modes

Despite being a robust component, the rear subframe is susceptible to certain issues, especially in regions with harsh climates or poor road conditions. Common problems include:

- Corrosion: Rust is a major concern, particularly in areas where salt is used on roads during winter. Corrosion can weaken the subframe and eventually lead to failure. Inspection of drain holes is vital to preventing water from being trapped inside of the assembly.

- Bushing Degradation: The rubber bushings can degrade over time due to exposure to heat, ozone, and road contaminants. Worn bushings can result in increased noise, vibration, and sloppy handling.

- Impact Damage: Hitting potholes or other road hazards can damage the subframe, causing bending, cracking, or misalignment.

- Cracked Welds: The welds that hold the subframe together can crack due to stress or fatigue.

- Differential Mount Failure: The differential mounting points on the subframe can crack or fail, especially if the differential bearings are worn or damaged, leading to excessive vibrations.

Diagnosing Subframe Problems

Several symptoms can indicate a problem with the rear subframe:

- Excessive noise and vibration: A rumbling, clunking, or vibrating noise from the rear of the vehicle, especially when driving over bumps, can indicate worn bushings or a damaged subframe.

- Poor handling: Sloppy or unpredictable handling, especially during cornering, can be a sign of a damaged or misaligned subframe.

- Uneven tire wear: Abnormal tire wear patterns can indicate a misalignment caused by a damaged subframe.

- Visual inspection: A thorough visual inspection of the subframe can reveal signs of rust, cracks, damage, or worn bushings.

Impact on Vehicle Performance

The rear subframe plays a critical role in the 2009 Murano AWD's overall performance:

- Ride Quality: A properly functioning subframe contributes to a smooth and comfortable ride by isolating noise and vibration.

- Handling: The subframe's rigidity and geometry are essential for precise and responsive handling.

- AWD Performance: The subframe's secure mounting of the rear differential ensures efficient and reliable power transfer to the rear wheels.

- Safety: The subframe contributes to the vehicle's overall crashworthiness by absorbing and distributing impact forces.

Maintenance and Repair

Regular maintenance and prompt repairs are essential for ensuring the longevity and performance of the rear subframe.

- Regular Inspections: The subframe should be inspected regularly for signs of rust, damage, or worn bushings.

- Rust Prevention: Applying rust-inhibiting coatings can help protect the subframe from corrosion.

- Bushing Replacement: Worn bushings should be replaced promptly to maintain proper handling and reduce noise and vibration.

- Subframe Replacement: If the subframe is severely damaged or corroded, it may need to be replaced. Replacing a subframe is a complex and labor-intensive procedure that should be performed by a qualified mechanic.

In conclusion, the 2009 Nissan Murano AWD rear subframe is a complex and crucial component that plays a vital role in the vehicle's ride quality, handling, AWD performance, and safety. Understanding its design, function, materials, common issues, and impact on vehicle performance is essential for maintaining its longevity and ensuring a safe and enjoyable driving experience. Regular inspections and prompt repairs are key to preventing costly and potentially dangerous problems. Understanding the function and potential failure points can greatly assist in early problem detection and preventative maintenance.