2009 Nissan Versa Clutch Replacement

So, your 2009 Nissan Versa's clutch is giving you trouble? You're not alone! Clutches, like any wear item, eventually need replacement. Let's walk through the common signs, what the replacement entails, and what you can expect.

Recognizing the Signs: Is Your Clutch on Its Way Out?

Before diving into a replacement, it's important to be sure the clutch is actually the culprit. Here are some telltale signs your 2009 Versa's clutch might be failing:

- Clutch Slipping: This is perhaps the most common symptom. You'll notice the engine RPMs rise higher than normal when accelerating, but the car doesn't accelerate as quickly as it should. It feels like the engine is working hard, but the power isn't fully transferring to the wheels. This is especially noticeable when going uphill or carrying a load. Think of it like trying to run on ice; your feet are moving (engine RPMs), but you aren't going anywhere (car acceleration).

- Difficulty Shifting: Are you having trouble getting the car into gear, especially first or reverse? Do you have to force the shifter, or does it grind? A worn clutch can make shifting difficult, because the clutch disc isn't fully disengaging from the flywheel.

- Clutch Chatter: This is a shuddering or vibrating feeling when engaging the clutch, particularly when starting from a stop. It often feels like the car is bucking or shaking.

- High Clutch Pedal Engagement Point: As the clutch wears, you'll have to release the clutch pedal further and further before the clutch engages. If the engagement point is right at the top of the pedal travel, it's a sign of significant wear.

- Unusual Noises: While less common, you might hear squealing, grinding, or rattling noises when pressing or releasing the clutch pedal. These noises can indicate worn-out clutch components or a damaged throw-out bearing.

- Burning Smell: A distinct burning smell, similar to burning rubber or brakes, can indicate a slipping clutch. This smell is the result of the clutch disc overheating due to excessive friction.

Important Note: Some of these symptoms can also be caused by other issues, such as a hydraulic problem in the clutch system (master or slave cylinder) or a problem with the shift linkage. Before assuming the clutch is bad, it's always a good idea to have a qualified mechanic inspect the system.

The Clutch Replacement Process: What to Expect

Replacing a clutch is a fairly involved process that typically requires specialized tools and expertise. Here's a general overview of what's involved:

- Preparation: The mechanic will disconnect the battery and lift the vehicle using a lift or jack stands. Safety is paramount here.

- Draining Fluids: The transmission fluid will need to be drained.

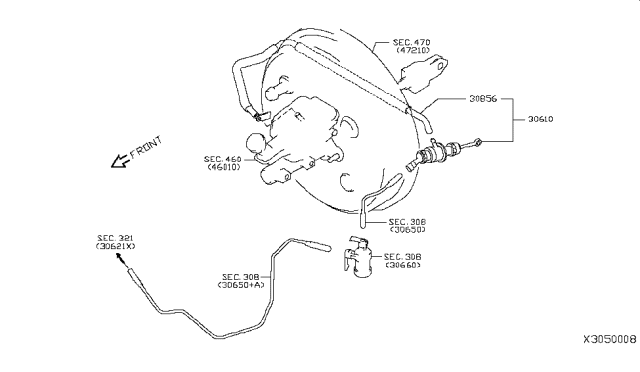

- Disconnecting Components: The mechanic will disconnect various components attached to the transmission, such as the shift linkage, driveshaft (if applicable), wiring harnesses, and any other related connections.

- Removing the Transmission: This is a critical step. The transmission is carefully removed from the engine. This usually involves supporting the engine with a support beam or jack.

- Inspecting the Flywheel: With the transmission removed, the flywheel is exposed. The mechanic will inspect it for wear, cracks, or hot spots. In many cases, the flywheel will need to be resurfaced or replaced to ensure proper clutch engagement.

- Replacing the Clutch Components: The old clutch disc, pressure plate, and throw-out bearing are removed. The new components are then installed in their place. The clutch disc must be carefully centered using a special alignment tool.

- Installing the Transmission: The transmission is carefully reinstalled onto the engine, ensuring proper alignment.

- Reconnecting Components: All the previously disconnected components are reconnected, including the shift linkage, driveshaft (if applicable), wiring harnesses, and other related connections.

- Refilling Fluids: The transmission is refilled with the correct type and amount of transmission fluid.

- Testing and Adjustment: The clutch is tested to ensure proper operation. The mechanic may also need to adjust the clutch pedal free play.

Common Parts Replaced During a Clutch Job:

- Clutch Disc: The friction disc that engages with the flywheel.

- Pressure Plate: The spring-loaded mechanism that presses the clutch disc against the flywheel.

- Throw-Out Bearing (Release Bearing): The bearing that presses against the pressure plate fingers to disengage the clutch.

- Pilot Bearing (or Bushing): A bearing or bushing located in the center of the flywheel that supports the input shaft of the transmission.

- Flywheel Bolts: One-time use bolts that secure the flywheel to the crankshaft.

- Transmission Fluid: Drained during the process and needs to be replaced with the correct type.

It's generally recommended to replace all these components at the same time to ensure a long-lasting and reliable repair. Skimping on one component can lead to premature failure of the others.

Tools Needed (For DIYers - Proceed with Caution!)

Warning: Clutch replacement is a complex job best left to experienced mechanics. If you're not comfortable working on your car's drivetrain, please seek professional help.

If you're an experienced DIYer and confident in your abilities, here's a list of tools you'll likely need:

- Jack and Jack Stands: Heavy-duty jack and jack stands to safely lift and support the vehicle.

- Wheel Chocks: To prevent the vehicle from rolling.

- Socket Set and Wrenches: A comprehensive set of sockets and wrenches in various sizes.

- Torque Wrench: For properly tightening bolts to the manufacturer's specifications.

- Impact Wrench (Optional): Can be helpful for removing stubborn bolts.

- Transmission Jack: A specialized jack designed to support and lower the transmission safely.

- Engine Support Beam: To support the engine while the transmission is removed.

- Clutch Alignment Tool: To center the clutch disc during installation. This is essential for proper clutch engagement.

- Flywheel Turning Tool: To hold the flywheel in place while removing and installing the flywheel bolts.

- Pry Bars: For separating the transmission from the engine.

- Drain Pan: To catch the transmission fluid.

- Shop Rags and Cleaners: For cleaning up spills and keeping your work area clean.

- Safety Glasses and Gloves: To protect your eyes and hands.

- Service Manual: A detailed service manual specific to your 2009 Nissan Versa is invaluable for providing step-by-step instructions and torque specifications.

Approximate Repair Costs: What to Budget For

The cost of a clutch replacement can vary depending on several factors, including:

- Labor Rates: Labor rates vary significantly between shops and regions.

- Parts Quality: Using high-quality parts will typically cost more but can provide better performance and longevity.

- Flywheel Resurfacing or Replacement: Whether the flywheel needs to be resurfaced or replaced will affect the overall cost.

- Any Additional Repairs: If any other issues are discovered during the repair, such as worn engine mounts or damaged shift linkage, the cost will increase.

As a general estimate, you can expect to pay between $800 and $1500 for a clutch replacement on a 2009 Nissan Versa. This includes the cost of parts and labor. It's always a good idea to get quotes from several different shops before making a decision. Be sure the quotes include a breakdown of parts and labor costs.

Important Tip: Ask the shop if they use a new throw-out bearing, pilot bearing and resurface the flywheel. These are critical for a proper clutch job.

Extending Clutch Life: Tips for Responsible Driving

While clutches eventually wear out, you can extend their lifespan by practicing good driving habits:

- Avoid Riding the Clutch: Don't rest your foot on the clutch pedal while driving. This causes the throw-out bearing to constantly engage, leading to premature wear.

- Shift Smoothly: Avoid jerky or abrupt shifts. Practice smooth and controlled clutch engagement.

- Avoid High-RPM Clutch Engagement: Don't rev the engine excessively when releasing the clutch. This puts unnecessary stress on the clutch disc.

- Minimize Slipping the Clutch: Avoid excessive clutch slippage, especially when starting from a stop on hills. Use the handbrake to prevent rolling backward.

- Don't Overload the Vehicle: Overloading the vehicle puts extra strain on the clutch, especially when starting from a stop or going uphill.

Conclusion

A worn clutch can make driving your 2009 Nissan Versa a frustrating experience. By understanding the symptoms of a failing clutch, knowing what the replacement process entails, and practicing good driving habits, you can keep your Versa running smoothly for years to come. If you suspect your clutch is failing, don't hesitate to seek professional help from a qualified mechanic. A timely repair can prevent further damage and ensure your safety on the road. Remember, it's better to address the issue sooner rather than later to avoid potentially more costly repairs down the line.