2010 Nissan Maxima Lower Control Arm

The 2010 Nissan Maxima, often lauded for its sporty performance and near-luxury feel, relies on a sophisticated suspension system to deliver that driving experience. A critical component of this system is the lower control arm. Often overlooked but absolutely essential, the lower control arm plays a vital role in maintaining vehicle stability, controlling wheel movement, and ensuring a comfortable ride. This in-depth look at the 2010 Maxima's lower control arm will explore its design, function, materials, and potential failure points.

Understanding the Lower Control Arm's Function

At its core, the lower control arm acts as a pivotal link between the vehicle's chassis (or frame) and the wheel hub assembly. Think of it as a horizontal lever that allows the wheel to move vertically (up and down) in response to road imperfections while maintaining a precise geometric relationship with the chassis. Without the control arm, the wheel would be free to move erratically, resulting in poor handling, instability, and an uncomfortable ride. The lower control arm, in conjunction with the upper control arm (where applicable), strut assembly, and other suspension components, forms a parallelogram-like structure that dictates the wheel's arc of travel.

The primary functions of the lower control arm can be summarized as follows:

- Lateral Support: Prevents the wheel from moving excessively side-to-side. This is crucial for maintaining proper track width and handling during cornering.

- Vertical Compliance: Allows the wheel to move vertically to absorb bumps and irregularities in the road surface, providing a smoother ride.

- Load Bearing: The lower control arm bears a significant portion of the vehicle's weight. This is especially true in front-wheel-drive vehicles like the Maxima, where the engine and transaxle add considerable weight over the front axle.

- Pivot Point: Serves as a critical pivot point for suspension movement, allowing the wheel to travel through its intended range of motion.

- Anti-Squat and Anti-Dive: The geometry of the control arm can be designed to influence the vehicle's response to acceleration (anti-squat) and braking (anti-dive), minimizing undesirable body motions.

Design and Construction of the 2010 Maxima's Lower Control Arm

The 2010 Nissan Maxima utilizes a MacPherson strut suspension design in the front. This means the lower control arm is a key component in supporting the vehicle's weight and controlling wheel movement. The design typically consists of the following:

- Arm Body: Usually constructed from stamped steel or forged aluminum. The 2010 Maxima's lower control arm is primarily made of stamped steel, chosen for its strength, durability, and cost-effectiveness. The shape is carefully engineered to provide maximum strength while minimizing weight. Gussets and reinforcing ribs are often incorporated to increase rigidity and prevent bending or twisting under load.

- Ball Joint: Located at the outboard end of the control arm, the ball joint connects the control arm to the steering knuckle (or spindle). This allows for pivotal movement in multiple planes, enabling the wheel to steer and articulate vertically. The ball joint is a wear item and is typically lubricated and sealed. Failure of the ball joint can lead to significant handling problems and potential safety hazards.

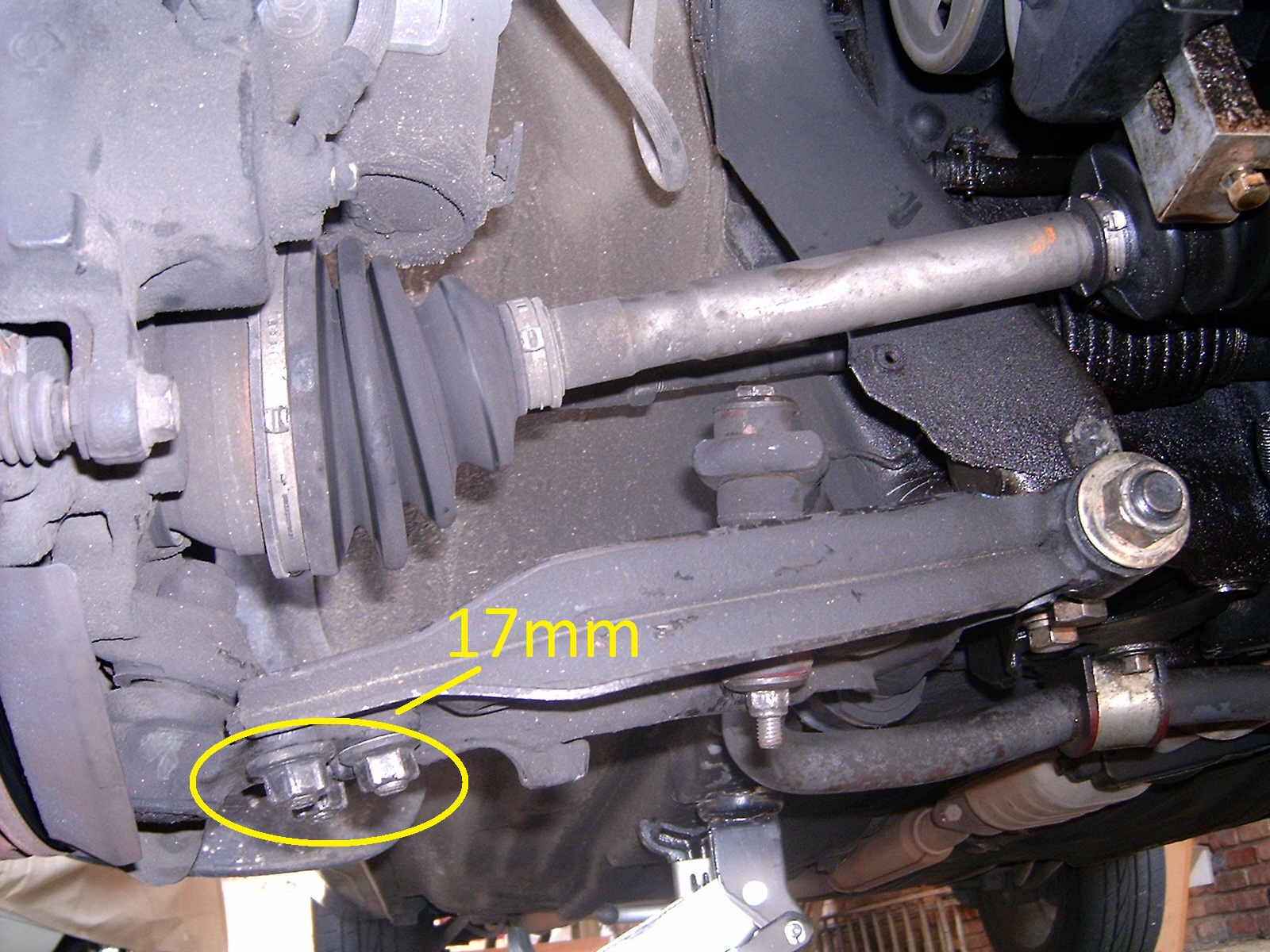

- Bushings: At the inboard end(s) of the control arm, bushings are used to attach the control arm to the vehicle's frame or subframe. These bushings are typically made of rubber or polyurethane and are designed to absorb vibrations and allow for controlled movement of the control arm. Bushings dampen noise and harshness transmitted from the road, contributing to ride comfort. The 2010 Maxima's lower control arm typically features two bushings, one at each mounting point.

- Mounting Points: These are the locations where the control arm attaches to the vehicle's chassis. The design and location of these mounting points are critical for determining the suspension geometry and handling characteristics.

The specific shape and dimensions of the lower control arm are carefully calculated to achieve the desired suspension geometry. This includes factors such as camber, caster, and toe, which all significantly impact the vehicle's handling and tire wear.

Materials and Manufacturing Processes

As mentioned earlier, the 2010 Nissan Maxima's lower control arm is primarily constructed from stamped steel. Let's delve deeper into why this material is chosen and the manufacturing processes involved:

- Steel: Offers a high strength-to-weight ratio and excellent durability. Stamped steel is a cost-effective manufacturing process that allows for the production of complex shapes in high volumes. Specific alloys of steel are chosen for their yield strength, tensile strength, and fatigue resistance.

- Stamping: This process involves pressing a flat sheet of steel between a die and a punch, forming the desired shape. The stamped components are then often welded together to create a complete control arm assembly.

- Bushings: Rubber bushings are typically vulcanized to metal sleeves for secure attachment to the control arm and chassis. The rubber compound is carefully formulated to provide the desired stiffness and damping characteristics. Polyurethane bushings are also sometimes used as aftermarket replacements. Polyurethane is more durable and offers less compliance than rubber, resulting in a firmer ride and improved handling.

- Ball Joints: The ball joint consists of a ball stud that articulates within a socket. The stud is typically made of hardened steel, and the socket is often made of a wear-resistant polymer. The joint is lubricated and sealed to prevent contamination and reduce friction.

Potential Failure Points and Common Issues

While the lower control arm is a robust component, it is subjected to significant stress and wear over time. Common failure points include:

- Ball Joint Failure: The ball joint is a common wear item and can fail due to wear and tear, lack of lubrication, or damage from impacts. Symptoms of a failing ball joint include clunking noises, loose steering, and uneven tire wear. In severe cases, the ball joint can separate completely, leading to a loss of control.

- Bushing Degradation: Rubber bushings can deteriorate over time due to exposure to the elements, oil, and road salt. Cracked, worn, or damaged bushings can cause excessive play in the suspension, leading to poor handling, vibrations, and noise.

- Control Arm Bending or Cracking: While less common, the control arm itself can bend or crack due to severe impacts, such as hitting a pothole or curb. This can compromise the structural integrity of the suspension and lead to dangerous handling characteristics.

- Corrosion: In regions with harsh winters and road salt, corrosion can weaken the control arm and accelerate the failure of bushings and ball joints.

Regular inspection of the lower control arm, including the ball joint and bushings, is essential for maintaining vehicle safety and performance. Look for signs of wear, damage, or corrosion. If you suspect a problem, have the vehicle inspected by a qualified mechanic.

Aftermarket Options and Upgrades

For enthusiasts looking to improve the performance of their 2010 Nissan Maxima, several aftermarket options are available for the lower control arm:

- Performance Bushings: Replacing the factory rubber bushings with polyurethane bushings can improve handling and responsiveness. However, this will typically result in a firmer ride.

- Adjustable Control Arms: These allow for fine-tuning of suspension geometry, such as camber and caster. This can be beneficial for vehicles that have been lowered or are used for racing.

- Lightweight Control Arms: Constructed from aluminum or other lightweight materials, these can reduce unsprung weight, improving handling and acceleration.

- Reinforced Control Arms: Designed for increased strength and durability, these are often used in vehicles that are subjected to extreme conditions or off-road use.

When considering aftermarket upgrades, it's important to choose reputable brands and ensure that the components are compatible with your vehicle. Consult with a qualified mechanic to determine the best options for your specific needs and driving style.

Conclusion

The lower control arm is a vital component of the 2010 Nissan Maxima's suspension system, playing a critical role in maintaining vehicle stability, controlling wheel movement, and ensuring a comfortable ride. Understanding its function, design, materials, and potential failure points can help you maintain your vehicle and ensure its safe and reliable operation. By performing regular inspections and addressing any issues promptly, you can keep your Maxima performing at its best for years to come. Ignoring a worn or damaged lower control arm can lead to serious safety consequences.