2012 Nissan Rogue Windshield Wipers

The 2012 Nissan Rogue, like most modern vehicles, relies on a seemingly simple system of windshield wipers to maintain visibility during inclement weather. However, beneath the surface lies a network of mechanical and electrical components working in concert to achieve effective and reliable windshield cleaning. This article will delve into the inner workings of the 2012 Rogue's wiper system, exploring its design, operation, and potential points of failure.

Wiper System Overview

The windshield wiper system in the 2012 Rogue comprises several key components:

- Wiper Motor: Provides the rotational force to drive the wiper arms.

- Wiper Linkage: Converts the rotary motion of the motor into the oscillating motion of the wiper arms.

- Wiper Arms: Connect to the linkage and hold the wiper blades against the windshield.

- Wiper Blades: The rubber elements that physically wipe water and debris from the windshield.

- Wiper Switch: Located on the steering column, allows the driver to control the wiper speed and activate the washer system.

- Washer Pump: Sprays washer fluid onto the windshield.

- Washer Fluid Reservoir: Holds the washer fluid.

- Wiring Harness: Connects all electrical components and delivers power and control signals.

- Fuses and Relays: Protect the electrical circuits from overloads and control the operation of the motor and pump.

The Wiper Motor: Heart of the System

The wiper motor is a relatively small, but powerful, 12-volt DC electric motor. Its primary function is to generate the rotational force required to move the wiper arms back and forth across the windshield. Inside the motor, electrical energy is converted into mechanical energy through the interaction of magnetic fields and armature windings. The 2012 Rogue's wiper motor likely utilizes a permanent magnet design, meaning that the magnetic field is generated by permanent magnets rather than electromagnets, simplifying the motor's construction and improving efficiency.

The motor is typically housed in a protective casing and mounted within the engine compartment, often near the base of the windshield. It's crucial that the motor is securely mounted to prevent excessive vibration and ensure proper operation of the linkage. Many modern wiper motors, including the one in the Rogue, incorporate a gear reduction system. This gearbox reduces the motor's high rotational speed to a more manageable speed for the wiper arms, while simultaneously increasing the torque available. Without this gear reduction, the wiper arms would move too quickly to effectively clear the windshield.

The 2012 Rogue's wiper motor likely features multiple speeds. These speeds are controlled by varying the voltage applied to the motor. Lower voltage results in slower rotation, while higher voltage increases the speed. This is typically achieved through a series of resistors or a pulse-width modulation (PWM) circuit within the wiper switch assembly. PWM allows for finer control of the motor speed by rapidly switching the voltage on and off, effectively averaging the voltage over time.

The Wiper Linkage: Converting Rotation to Oscillation

The wiper linkage is a crucial mechanical assembly that translates the rotary motion of the wiper motor into the oscillating (back and forth) motion of the wiper arms. This linkage system typically consists of a series of interconnected rods, levers, and pivot points. The design of the linkage dictates the sweep pattern of the wiper blades and ensures that both blades move in a coordinated manner. In the 2012 Rogue, the linkage is likely a four-bar linkage, a common and effective design for windshield wiper systems.

The motor's rotary output shaft is connected to one end of the linkage system. As the motor rotates, this initial rotation is transferred through the linkage, causing the other ends of the linkage to move in a reciprocating motion. This reciprocating motion is then directly connected to the wiper arms, causing them to sweep across the windshield. The specific geometry of the linkage is carefully calculated to achieve the desired sweep angle and coverage area.

The linkage is typically constructed from durable materials such as steel or aluminum to withstand the forces generated by the motor and the resistance encountered from the windshield. Regular lubrication of the linkage pivot points is essential to prevent wear and ensure smooth operation. A lack of lubrication can lead to binding, increased motor strain, and eventual failure of the linkage.

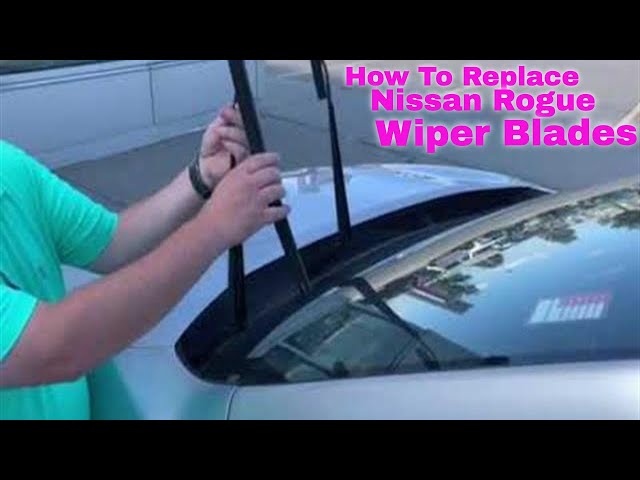

Wiper Arms and Blades: The Interface with the Elements

The wiper arms are the metal extensions that connect the wiper linkage to the wiper blades. They are designed to exert a consistent pressure on the blades, ensuring proper contact with the windshield. The arms are usually spring-loaded to maintain this pressure, compensating for variations in windshield curvature and blade wear.

The wiper blades themselves are the rubber components that directly wipe away water and debris from the windshield. They consist of a flexible rubber element attached to a supporting frame. The quality of the rubber is critical, as it must remain pliable and resistant to cracking and tearing, even in extreme temperatures. Modern wiper blades often incorporate features such as aerodynamic spoilers to improve performance at higher speeds and reduce wind noise.

The blades are designed to be easily replaceable, as they are subject to wear and tear from constant exposure to the elements. Regular inspection and replacement of the wiper blades are essential for maintaining optimal visibility. Streaking, skipping, or smearing are all signs that the blades need to be replaced.

The Washer System: Aiding Visibility

The washer system complements the wiper system by spraying washer fluid onto the windshield. This fluid helps to remove stubborn dirt, grime, and insect residue that the wiper blades alone may not be able to clear. The system consists of a washer fluid reservoir, an electric washer pump, and a series of nozzles that direct the fluid onto the windshield.

The washer pump is typically a small, submersible electric pump located within the washer fluid reservoir. When the driver activates the washer switch, the pump draws fluid from the reservoir and pressurizes it, sending it through the tubing to the nozzles. The nozzles are strategically positioned to ensure even distribution of the fluid across the windshield.

The washer fluid itself is a specially formulated solution containing detergents and anti-freezing agents. The detergents help to dissolve dirt and grime, while the anti-freezing agents prevent the fluid from freezing in cold weather, which could damage the pump and tubing.

Electrical System and Control

The entire windshield wiper system is controlled by the vehicle's electrical system. The wiper switch, located on the steering column, allows the driver to select different wiper speeds, activate the intermittent wiper function (if equipped), and activate the washer system. The switch sends signals to the wiper motor and washer pump, instructing them to operate at the desired speed or to spray washer fluid.

Fuses and relays protect the electrical circuits of the wiper system from overloads and short circuits. A blown fuse can prevent the wipers from operating altogether. The relay acts as an electrically controlled switch, allowing a low-current signal from the wiper switch to control a higher-current circuit that powers the wiper motor. This protects the wiper switch from damage.

The 2012 Rogue may also incorporate a rain sensor system. Rain sensors automatically activate the wipers when they detect moisture on the windshield. These systems typically use infrared light to detect the presence of water droplets. When water droplets are present, they reflect the infrared light differently, triggering the wipers to activate. The sensitivity of the rain sensor can usually be adjusted by the driver.

Potential Points of Failure

The windshield wiper system, like any mechanical and electrical system, is subject to wear and tear and can experience failures over time. Some common points of failure include:

- Wiper Motor Failure: The motor can burn out due to excessive use, worn brushes, or internal shorts.

- Linkage Binding: The linkage can become stiff or seize due to lack of lubrication, corrosion, or physical damage.

- Wiper Blade Deterioration: The rubber blades can crack, tear, or become hardened, reducing their effectiveness.

- Washer Pump Failure: The pump can fail due to a clogged intake, a burned-out motor, or a frozen fluid reservoir.

- Electrical Issues: Fuses can blow, relays can fail, and wiring connections can corrode, disrupting the flow of power to the system.

- Wiper Arm Damage: The wiper arms can become bent or damaged, preventing them from applying adequate pressure to the blades.

- Washer Nozzle Clogging: The washer nozzles can become clogged with debris, preventing them from spraying fluid properly.

Regular maintenance, including lubrication of the linkage, inspection and replacement of the wiper blades, and ensuring proper washer fluid levels, can help to prevent many of these failures and prolong the life of the windshield wiper system.

Understanding the intricacies of the 2012 Nissan Rogue's windshield wiper system allows for better troubleshooting and maintenance, ensuring clear visibility and safe driving in all weather conditions.

By recognizing the function and interrelation of each component, owners can better diagnose issues and perform necessary repairs or replacements, optimizing the system's performance and extending its lifespan.