2012 Nissan Sentra Oxygen Sensor Location

The 2012 Nissan Sentra, like most modern vehicles, relies heavily on its oxygen (O2) sensors to maintain optimal engine performance, fuel efficiency, and emissions control. These sensors are critical components within the engine management system, providing real-time data about the exhaust gas composition to the Engine Control Unit (ECU). Understanding the location and function of these sensors is essential for diagnostics, maintenance, and repairs. This guide provides an in-depth look at the O2 sensor locations within the 2012 Nissan Sentra's exhaust system.

Understanding Oxygen Sensor Function

Before diving into the specific locations, it's important to understand the role of oxygen sensors in the combustion process. An internal combustion engine strives for a stoichiometric air-fuel ratio, ideally 14.7:1 (air to fuel by mass). This ratio allows for complete combustion, minimizing harmful emissions and maximizing power. However, various factors can cause deviations from this ideal ratio, leading to either a lean condition (excess air) or a rich condition (excess fuel).

Oxygen sensors monitor the amount of oxygen in the exhaust gas stream. This information is then relayed to the ECU, which uses it to adjust the fuel injection system, ensuring the air-fuel mixture remains as close to stoichiometric as possible. There are typically two types of oxygen sensors:

- Upstream (Pre-Catalytic Converter) Sensors: These sensors, often referred to as Air-Fuel Ratio (A/F) sensors in some contexts, are located before the catalytic converter. Their primary function is to directly measure the oxygen content of the exhaust gas coming directly from the engine. This provides the ECU with the most accurate feedback for precise fuel trim adjustments. They tend to be wide-band sensors, providing a more granular reading than downstream sensors.

- Downstream (Post-Catalytic Converter) Sensors: Located after the catalytic converter, these sensors primarily monitor the efficiency of the catalytic converter. While they also provide some feedback about the air-fuel ratio, their main purpose is to ensure that the catalytic converter is effectively reducing harmful emissions. These sensors generally produce a narrower range of voltage outputs compared to upstream sensors.

2012 Nissan Sentra Oxygen Sensor Locations

The 2012 Nissan Sentra, typically equipped with a 2.0L four-cylinder engine (QR20DE) or sometimes a 2.5L (QR25DE), utilizes two oxygen sensors. Their locations are as follows:

Upstream Oxygen Sensor (Sensor 1) Location

The upstream oxygen sensor, also known as Sensor 1, is situated on the exhaust manifold, before the catalytic converter. To locate it:

- Open the hood of your 2012 Nissan Sentra.

- Locate the exhaust manifold. This is the component bolted directly to the engine's cylinder head where exhaust gases are collected. It's usually made of cast iron or stainless steel.

- Trace the exhaust manifold downwards. You will find the upstream oxygen sensor screwed into the manifold, typically before the point where the manifold connects to the catalytic converter.

- The sensor will have an electrical connector attached to it. The wiring harness for the sensor will usually be clipped to the engine or nearby components.

Important Note: The upstream sensor can be difficult to access due to its location near the hot exhaust manifold and other engine components. Heat shields may be in place to protect surrounding components from the manifold's heat. Exercise caution when working in this area.

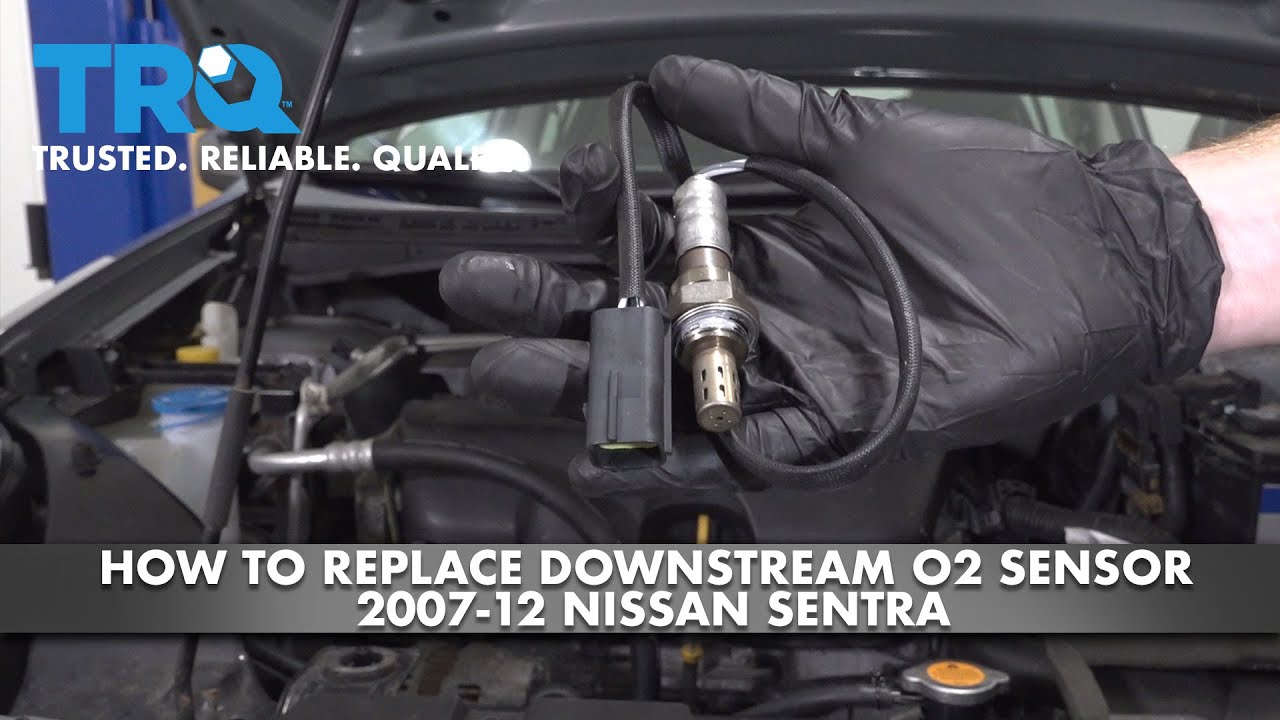

Downstream Oxygen Sensor (Sensor 2) Location

The downstream oxygen sensor, or Sensor 2, is located after the catalytic converter, typically in the exhaust pipe section immediately following the converter. To locate it:

- Locate the catalytic converter. This is a large, usually cylindrical component in the exhaust system. It's often enclosed in a heat shield.

- Trace the exhaust pipe downstream (towards the rear of the vehicle) from the catalytic converter.

- You will find the downstream oxygen sensor screwed into the exhaust pipe, usually within a few inches of the catalytic converter's outlet.

- Like the upstream sensor, it will have an electrical connector and associated wiring harness.

Note: The downstream sensor is generally more accessible than the upstream sensor, as it is typically located in a less crowded area under the vehicle. However, you may still need to raise the vehicle on ramps or jack stands for better access. Always use proper safety precautions when working under a vehicle.

Identifying the Correct Sensor

Visually, the two oxygen sensors may appear similar, but it is crucial to identify the correct sensor before replacement. Incorrectly installing the wrong sensor can lead to performance issues and diagnostic trouble codes (DTCs). Here are some tips for identifying the correct sensor:

- Wiring Harness Length: The upstream and downstream sensors typically have different wiring harness lengths. The upstream sensor's harness will usually be shorter, as it is located closer to the engine.

- Connector Type: While connector shapes and pin arrangements can vary even within the same vehicle model year, note the color and configuration of the connector on the original sensor before replacement.

- Part Number: The most reliable way to ensure you are using the correct sensor is to check the part number stamped on the sensor body or printed on the wiring harness. You can then cross-reference this part number with a parts catalog or online database.

- Diagnostic Trouble Codes (DTCs): If you are replacing a sensor due to a DTC, the code itself can often indicate which sensor is faulty (e.g., P0131 - O2 Sensor Circuit Low Voltage (Bank 1, Sensor 1)). Consult a reliable repair manual or online resource to interpret the DTCs.

Tools Required for Oxygen Sensor Replacement

Replacing an oxygen sensor is a relatively straightforward task, but it requires specific tools. Here’s a list of what you’ll typically need:

- Oxygen Sensor Socket: This is a specialized socket designed to fit around the oxygen sensor's wiring harness. It allows you to loosen and tighten the sensor without damaging the wires.

- Wrench or Socket Set: A standard wrench or socket set can be used in conjunction with the oxygen sensor socket.

- Penetrating Oil: Applying penetrating oil to the sensor threads can help loosen a corroded sensor.

- Torque Wrench: A torque wrench is essential for properly tightening the new sensor to the manufacturer's specified torque. Overtightening can damage the sensor or exhaust manifold.

- Jack and Jack Stands or Ramps: These are needed to safely raise the vehicle for access to the downstream sensor.

- Gloves: Wearing gloves will protect your hands from dirt, grease, and hot exhaust components.

- Safety Glasses: Protect your eyes from debris.

Potential Problems and Considerations

Several factors can affect the performance and lifespan of oxygen sensors:

- Contamination: Oil leaks, coolant leaks, and excessive carbon buildup can contaminate the sensor, reducing its accuracy and lifespan.

- Corrosion: Exposure to road salt, moisture, and extreme temperatures can corrode the sensor's threads and electrical connections.

- Age and Wear: Oxygen sensors degrade over time, losing their ability to accurately measure oxygen content.

If you suspect an oxygen sensor is faulty, it's important to diagnose the problem correctly before replacing the sensor. Common symptoms of a failing oxygen sensor include:

- Poor fuel economy

- Rough idling

- Hesitation during acceleration

- Increased emissions

- Check Engine Light (CEL) with related DTCs

Using a scan tool to read the sensor data can help determine if the sensor is functioning properly. A healthy upstream sensor should fluctuate rapidly between lean and rich conditions, while a healthy downstream sensor should exhibit a more stable voltage reading.

Important Safety Notice: Always disconnect the negative battery terminal before working on any electrical components of your vehicle. Allow the exhaust system to cool completely before attempting to remove or replace oxygen sensors, as they can become extremely hot during engine operation.