240sx Fuel Feed And Return Line Routing And Upgrade Options

Alright, let's talk about fuel lines on your 240SX. Whether you're chasing more power with engine modifications, dealing with frustrating fuel leaks, or just wanting to freshen up those old rubber lines, understanding your fuel feed and return line routing is crucial. We'll cover common problems, upgrade options, and what you need to get the job done right. Think of this as your guide to fuel system sanity for your S-chassis.

Understanding the Stock Fuel System

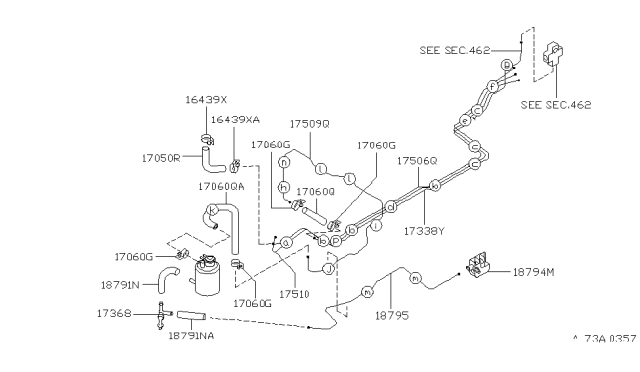

Before we dive into upgrades, let's review the stock setup. On a 240SX (S13 or S14), the fuel system is a pretty straightforward, closed-loop design. Fuel is drawn from the fuel tank by the fuel pump, travels up the fuel feed line to the fuel rail on the engine, where it's distributed to the injectors. Any unused fuel then returns to the tank via the fuel return line. A fuel pressure regulator (FPR) maintains consistent fuel pressure at the rail.

The stock lines are typically made of rubber, which can degrade over time due to exposure to fuel, heat, and the elements. This degradation is a common cause of leaks and fuel system inefficiencies. The factory fuel lines are also sized for the stock engine output. If you’ve significantly increased your horsepower, these lines can become a bottleneck, preventing your engine from getting the fuel it needs.

Common 240SX Fuel Line Issues

- Fuel Leaks: The most common problem, often originating at connection points or from cracks in the aged rubber lines. You might smell fuel, especially after driving.

- Fuel Starvation: If you've increased power, the stock lines might not be able to supply enough fuel, leading to poor performance, hesitation, or even engine damage.

- Poor Fuel Pressure Regulation: A failing FPR can cause inconsistent fuel pressure, leading to rough running and potential damage.

- Ethanol Compatibility: Older rubber fuel lines can degrade with ethanol-blended fuels, leading to premature failure.

- Restricted Flow: Corrosion or build-up inside the lines can restrict fuel flow, affecting performance.

Troubleshooting Fuel Line Problems

If you suspect a fuel line issue, here's a basic troubleshooting approach:

- Visual Inspection: Carefully inspect all fuel lines, paying close attention to connections, bends, and areas near heat sources. Look for cracks, swelling, or signs of fuel leakage.

- Smell Test: A strong fuel odor, especially in the engine bay or near the fuel tank, is a strong indicator of a leak.

- Fuel Pressure Check: Use a fuel pressure gauge to check the pressure at the fuel rail. Compare the reading to the factory specifications (typically around 36-43 psi at idle).

- Leak Down Test: After shutting off the engine, observe the fuel pressure gauge. A rapid drop in pressure indicates a leak somewhere in the system.

Important Safety Note: Fuel is highly flammable. Always work in a well-ventilated area, disconnect the battery, and have a fire extinguisher readily available.

Upgrade Options and Routing Strategies

Now, let's explore your options for upgrading your 240SX's fuel lines. Here are some common approaches:

Option 1: Replacement with OEM-Style Lines

For a straightforward repair, you can replace the old rubber lines with new ones of the same type. This is the most cost-effective option, but it doesn't address the limitations of the stock system, especially if you've increased power. Expect to pay around $50-$150 for a set of replacement rubber lines.

Option 2: Stainless Steel Braided Lines with AN Fittings

This is a popular and highly recommended upgrade. Stainless steel braided lines are much more durable and resistant to degradation than rubber lines. They also offer better flow characteristics and are compatible with ethanol-blended fuels. AN (Army-Navy) fittings provide a secure and leak-free connection. This usually involves replacing the entire fuel feed and return line from the fuel filter up to the fuel rail. Sometimes people replace from the tank forward.

Here's what's involved:

- Line Sizing: For most moderately modified 240SXs (up to around 400-450hp), -6AN (3/8") lines are sufficient for both feed and return. For higher horsepower builds, consider -8AN (1/2") lines for the feed and -6AN for the return.

- Fittings: You'll need AN fittings to connect the lines to the fuel filter, fuel rail, and fuel pressure regulator. Make sure to use fittings that are compatible with the type of fuel you'll be using (e.g., E85).

- Routing: You can generally follow the factory routing, but consider rerouting the lines away from heat sources like the exhaust manifold. Use clamps to secure the lines and prevent them from rubbing against other components.

- Fuel Pressure Regulator (FPR): Consider upgrading your FPR to an adjustable aftermarket unit. This allows you to fine-tune your fuel pressure for optimal performance. This is highly recommended with any fuel line upgrade.

Tools Needed:

- AN Wrench Set (essential for tightening AN fittings properly)

- Line Cutter (for clean cuts on stainless steel braided lines)

- Flare Nut Wrenches (for the fuel filter connections)

- Socket Set and Wrenches

- Screwdrivers

- Fuel Line Disconnect Tool (for some factory connections)

- Safety Glasses and Gloves

Approximate Cost: $300 - $800+, depending on the brand, line size, and included components (FPR, fuel rail, etc.). Labor costs at a shop could add another $200-$500.

Option 3: Complete Fuel System Upgrade

For high-horsepower builds, a complete fuel system upgrade might be necessary. This includes replacing the fuel pump, fuel filter, fuel lines, fuel rail, and fuel pressure regulator. This ensures that your engine receives an adequate and consistent supply of fuel. It's often done in conjunction with larger injectors.

Considerations:

- Fuel Pump: Choose a fuel pump that can supply enough fuel for your target horsepower level. Walbro 255lph pumps are a popular choice for many 240SX builds. Aeromotive and AEM are good higher end options.

- Fuel Rail: An aftermarket fuel rail with larger internal diameter improves fuel distribution to the injectors. Ensure the rail is compatible with your injectors and intake manifold.

- Fuel Filter: A high-flow fuel filter will help maintain fuel cleanliness and prevent clogging of the injectors.

- Fuel Cell: For dedicated race cars, consider replacing the stock fuel tank with a fuel cell for improved safety and fuel management.

Step-by-Step Guide (Stainless Steel Braided Lines)

While professional installation is recommended, here's a general overview of how to install stainless steel braided fuel lines:

- Preparation: Disconnect the battery, relieve fuel pressure (by removing the fuel pump fuse and starting the engine until it stalls), and gather all necessary tools and parts.

- Removal: Carefully disconnect and remove the old fuel lines. Take pictures of the routing for reference.

- Installation: Install the new AN fittings onto the fuel filter, fuel rail, and FPR. Ensure they are tightened properly using AN wrenches.

- Routing: Route the new stainless steel braided lines, following the factory routing as closely as possible. Secure the lines with clamps to prevent rubbing.

- Connection: Connect the lines to the AN fittings, ensuring a secure and leak-free connection.

- Testing: Reconnect the battery, prime the fuel system, and check for leaks. Start the engine and monitor fuel pressure.

Routing Tips and Considerations

- Heat Protection: Route fuel lines away from heat sources like the exhaust manifold and turbocharger. Use heat shielding or sleeves to protect the lines if necessary.

- Clearance: Ensure the lines have adequate clearance from moving parts like the steering shaft and suspension components.

- Support: Use clamps to secure the lines and prevent them from sagging or rubbing.

- Fuel Filter Placement: Keep the fuel filter accessible for easy maintenance.

- Professional Help: If you're not comfortable working on your fuel system, seek professional assistance from a qualified mechanic.

Upgrading your 240SX's fuel lines is a worthwhile investment, especially if you're looking to improve performance, reliability, and fuel system efficiency. By understanding the stock system, troubleshooting common problems, and choosing the right upgrade options, you can ensure that your engine gets the fuel it needs to perform its best. Remember to prioritize safety and take your time to do the job right. Good luck, and happy motoring!

Disclaimer: This article is for informational purposes only and should not be considered a substitute for professional advice. Always consult with a qualified mechanic before performing any modifications to your vehicle.