240sx Manual Transmission Sensors

The 240sx, particularly those equipped with the robust and beloved manual transmission, relies on a few key sensors to function optimally. Understanding these sensors, their purpose, potential failure modes, and basic troubleshooting steps is crucial for maintaining your S-chassis. While the manual transmission itself is a mechanical marvel, the ECU (Engine Control Unit) needs specific data to manage engine performance, idle, and even prevent certain mishaps.

Vehicle Speed Sensor (VSS)

Perhaps the most critical sensor on the 240sx manual transmission is the Vehicle Speed Sensor (VSS). This sensor does exactly what the name implies: it measures the speed of the vehicle. This information is then relayed to the ECU for various functions.

Function

The VSS provides critical data to the ECU for:

- Speedometer: Obviously, the VSS is directly responsible for the speedometer reading on your instrument cluster.

- Idle Control: The ECU uses vehicle speed to adjust the idle speed, especially when coming to a stop. This prevents the engine from stalling.

- Fuel Cutoff: At high speeds, the ECU may implement a fuel cutoff to prevent over-revving the engine (though this is less common on stock setups).

- Cruise Control: If equipped, the cruise control system relies heavily on the VSS to maintain a set speed.

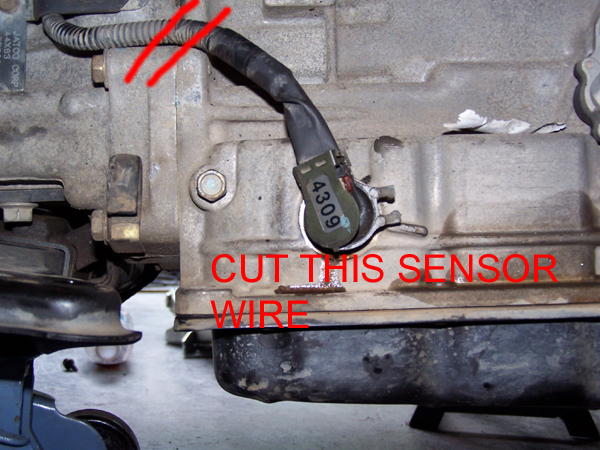

Location

The VSS is typically located on the transmission housing, near the output shaft. It's usually a cylindrical sensor with a two or three-wire connector.

Operation

The VSS generally operates using a reluctor wheel or a toothed gear that rotates with the transmission output shaft. As the gear spins, it induces a magnetic field in the sensor, which generates a pulsed electrical signal. The frequency of these pulses is directly proportional to the vehicle speed. The ECU reads these pulses and converts them into a speed value.

Failure Modes

Common symptoms of a failing VSS include:

- Erratic or non-functioning speedometer. This is the most obvious symptom.

- Rough or stalling idle, especially when coming to a stop. The ECU can't properly compensate for the vehicle slowing down.

- Cruise control malfunction.

- Check engine light (CEL) with codes related to VSS signal issues. Common codes include P0500 (Vehicle Speed Sensor A Malfunction).

Troubleshooting

Here's a basic troubleshooting process:

- Check the Connector: Ensure the connector is properly seated and free from corrosion. Use electrical contact cleaner if necessary.

- Inspect Wiring: Look for any damaged or broken wires leading to the sensor.

- Test the Sensor: Using a multimeter, you can test the sensor's output. While the wheel is turning (you'll need to safely lift the rear wheels for this), the voltage should fluctuate. Consult your 240sx repair manual for specific voltage ranges. Safety Note: Ensure the car is properly secured before attempting this test. Use jack stands and wheel chocks.

- Scan for Codes: Use an OBD-II scanner to check for any stored VSS-related codes. Clearing the codes after repair is essential.

- Replace the Sensor: If the sensor tests bad, replacement is usually the best course of action.

Neutral Position Switch (NPS)

The Neutral Position Switch (NPS), sometimes referred to as the Inhibitor Switch, is another important sensor on the 240sx manual transmission. While less directly related to engine performance during driving than the VSS, it plays a vital role during starting and idle.

Function

The primary function of the NPS is to inform the ECU whether the transmission is in neutral or not. This information is used for:

- Starting the Engine: The NPS prevents the engine from starting unless the transmission is in neutral or the clutch pedal is depressed (on models equipped with a clutch switch – see below). This is a safety feature to prevent accidental starts in gear.

- Idle Control: Similar to the VSS, the ECU may use the NPS signal to fine-tune the idle speed when the transmission is in neutral.

Location

The NPS is typically located on the transmission housing, often near the shifter linkage. It's a simple switch that is activated or deactivated by the position of the shifter.

Operation

The NPS is essentially a simple on/off switch. When the transmission is in neutral, the switch is closed, completing the circuit and sending a signal to the ECU. When the transmission is in gear, the switch is open, breaking the circuit.

Failure Modes

Common symptoms of a failing NPS include:

- Engine will not start. Even when the key is turned, the starter will not engage if the NPS is faulty and incorrectly indicating that the car is in gear.

- Intermittent starting issues. The engine may start sometimes, but not others, depending on the position of the shifter.

- Rough or unstable idle. This is less common but can occur if the ECU is receiving an incorrect signal from the NPS.

- Check Engine Light (CEL), although less common than with a VSS issue.

Troubleshooting

Troubleshooting the NPS is relatively straightforward:

- Check the Connector: As with the VSS, inspect the connector for proper seating and corrosion.

- Test the Switch: Using a multimeter, check the continuity of the switch. It should show continuity (a closed circuit) when the transmission is in neutral and no continuity (an open circuit) when in gear.

- Adjust the Switch: Some NPS models are adjustable. Consult your 240sx repair manual for instructions on how to properly adjust the switch position.

- Replace the Switch: If the switch tests bad, replacement is the best solution.

Clutch Switch (Not All Models)

Some 240sx models, especially those with more advanced ECU features or aftermarket modifications, may also utilize a Clutch Switch. This switch is located on the clutch pedal assembly.

Function

The clutch switch's primary function is to inform the ECU when the clutch pedal is depressed. This information can be used for:

- Starting the Engine: As mentioned earlier, it may act as a redundant safety feature, allowing the engine to start even if the NPS malfunctions, as long as the clutch is depressed.

- Idle Control: The ECU might slightly adjust the idle speed when the clutch is depressed to prevent stalling during gear changes.

- Launch Control/Flat Foot Shifting (Aftermarket ECUs): With aftermarket ECUs, the clutch switch is crucial for implementing advanced features like launch control and flat-foot shifting (maintaining full throttle during gear changes).

Location

The clutch switch is located on the clutch pedal assembly, usually near the top of the pedal's travel.

Operation

Like the NPS, the clutch switch is a simple on/off switch. When the clutch pedal is depressed, the switch is activated (closed circuit). When the clutch pedal is released, the switch is deactivated (open circuit).

Failure Modes

Common symptoms of a failing clutch switch include:

- Engine will not start unless the clutch pedal is depressed (even in neutral).

- Inconsistent idle speed when the clutch is depressed.

- Launch control/flat-foot shifting malfunctions (if equipped).

Troubleshooting

Troubleshooting the clutch switch is similar to the NPS:

- Check the Connector: Inspect the connector for proper seating and corrosion.

- Test the Switch: Using a multimeter, check the continuity of the switch. It should show continuity when the clutch pedal is depressed and no continuity when released.

- Adjust the Switch: Some clutch switches are adjustable.

- Replace the Switch: If the switch tests bad, replacement is the solution.

Conclusion

The sensors associated with the 240sx manual transmission, particularly the VSS and NPS, are essential for proper engine operation and safety. While the clutch switch is less common on stock vehicles, it's important to be aware of its function, especially if you're running an aftermarket ECU with advanced features. By understanding these sensors, their functions, and potential failure modes, you can effectively troubleshoot issues and keep your 240sx running smoothly. Remember to always consult your 240sx repair manual for specific instructions and torque specifications. Working on your vehicle can be dangerous. Always take necessary safety precautions, including using jack stands, wheel chocks, and disconnecting the battery when working on electrical components.