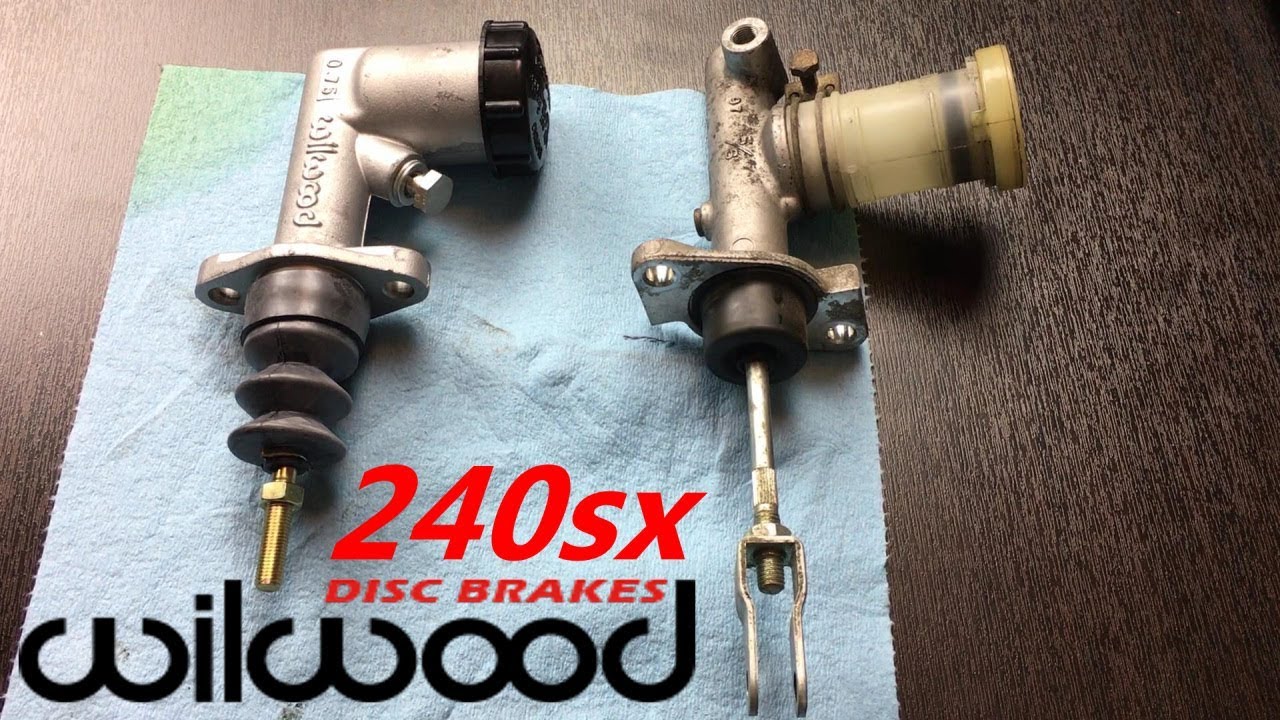

240sx Wilwood Clutch Master Cylinder

The Nissan 240SX, a darling of the drift and tuner communities, often finds its aging components struggling to keep up with performance modifications. One crucial area frequently addressed is the clutch system. Upgrading to a Wilwood clutch master cylinder is a popular choice, offering improved feel, durability, and the capacity to handle higher clutch pressures from performance clutches. This guide will delve into the technical aspects of installing and understanding a Wilwood clutch master cylinder in a 240SX.

Understanding the Stock 240SX Clutch System

Before diving into the Wilwood upgrade, it's essential to grasp how the factory 240SX clutch system operates. It's a hydraulic system, meaning it uses fluid pressure to transmit force from the pedal to the clutch fork. The main components include:

- Clutch Pedal: Where the driver initiates the clutch engagement/disengagement.

- Clutch Master Cylinder: Converts the pedal's mechanical input into hydraulic pressure. A piston inside the cylinder pushes fluid through the lines.

- Clutch Line: Transfers the pressurized hydraulic fluid. Often made of rubber in stock form, susceptible to expansion under pressure.

- Clutch Slave Cylinder: Receives the hydraulic pressure from the master cylinder and converts it back into mechanical force to move the clutch fork.

- Clutch Fork: Actuates the throw-out bearing, pressing against the clutch pressure plate.

- Clutch Pressure Plate: Applies pressure to the clutch disc, holding it against the flywheel to transmit engine power to the transmission.

The stock 240SX master cylinder, while adequate for a factory setup, often exhibits limitations when paired with aftermarket clutches that have higher clamping forces. These limitations can manifest as a soft pedal feel, inconsistent engagement, and even premature failure of the master cylinder itself.

Why Upgrade to a Wilwood Clutch Master Cylinder?

Wilwood offers a significant upgrade for several reasons:

- Improved Pedal Feel: Wilwood master cylinders are generally made with tighter tolerances and use high-quality materials, leading to a more precise and responsive pedal feel. This allows for better clutch control and modulation.

- Increased Durability: The stock master cylinder is prone to leaks and internal failures, especially under increased stress. Wilwood master cylinders are designed for performance applications and built to withstand higher pressures and temperatures.

- Larger Bore Options: Wilwood offers master cylinders with varying bore sizes. A larger bore can displace more fluid, reducing pedal travel required to fully disengage the clutch. This is particularly beneficial with performance clutches requiring a larger stroke. However, selecting the correct bore size is crucial, as too large a bore can result in a very stiff pedal.

- Adjustability: Some Wilwood models offer adjustable pushrods, allowing fine-tuning of the pedal engagement point.

- Compatibility with Aftermarket Clutches: Designed to handle the increased clamping force of performance clutches, preventing premature failure and ensuring consistent performance.

Technical Considerations: Bore Size and Stroke

Choosing the correct bore size for the Wilwood master cylinder is critical for optimal performance. Bore size directly impacts pedal feel and the amount of clutch slave cylinder travel.

- Bore Size: A larger bore diameter requires less pedal travel to achieve the same amount of fluid displacement. This can result in a shorter, firmer pedal feel. However, it also requires more force to actuate, potentially leading to a stiffer pedal. Conversely, a smaller bore requires more pedal travel for the same fluid displacement, resulting in a longer, softer pedal feel and reduced actuation force.

- Stroke: The stroke refers to the distance the piston travels within the master cylinder. The stroke of the master cylinder must be sufficient to fully actuate the slave cylinder and disengage the clutch. Insufficient stroke can lead to incomplete clutch disengagement, causing difficulty shifting gears.

For most 240SX applications with moderately upgraded clutches, a Wilwood master cylinder with a bore size in the range of 5/8" (0.625") to 3/4" (0.75") is often recommended. It's crucial to research and consult with Wilwood or experienced 240SX tuners to determine the ideal bore size based on the specific clutch and driving style.

Installation Process: A Step-by-Step Guide

Note: This is a general guide; specific installation procedures may vary depending on the Wilwood kit and the 240SX model year. Always consult the Wilwood installation instructions provided with the kit.

- Preparation: Gather all necessary tools, including wrenches, sockets, flare nut wrenches, brake fluid, a bleeding kit, and safety glasses. Disconnect the negative terminal of the battery.

- Removal of the Stock Master Cylinder:

- Locate the stock clutch master cylinder in the engine bay, typically mounted on the firewall.

- Disconnect the clutch line from the master cylinder using a flare nut wrench. Be prepared for brake fluid to spill; have a container ready.

- Disconnect the pushrod from the clutch pedal inside the cabin. This often involves removing a retaining clip or cotter pin.

- Remove the bolts securing the master cylinder to the firewall.

- Carefully remove the stock master cylinder.

- Installation of the Wilwood Master Cylinder:

- Mount the Wilwood master cylinder to the firewall using the provided hardware. Some kits may require drilling new holes or using an adapter plate.

- Connect the pushrod to the clutch pedal. Ensure proper alignment and secure it with the retaining clip or cotter pin. Adjust the pushrod length as needed.

- Connect the clutch line to the Wilwood master cylinder. Use a new copper crush washer for a leak-free seal. Consider upgrading to a stainless steel braided clutch line for improved durability and reduced expansion.

- Bleeding the Clutch System:

- This is a crucial step to remove air from the hydraulic system. Air in the system will result in a spongy pedal feel and poor clutch engagement.

- There are several methods for bleeding the clutch system, including the traditional two-person method, using a vacuum bleeder, or a pressure bleeder.

- The basic process involves opening the bleeder screw on the clutch slave cylinder while someone pumps the clutch pedal. Repeat this process until clear, bubble-free fluid emerges from the bleeder screw.

- Verification and Adjustment:

- After bleeding the system, check for leaks around the master cylinder and clutch line connections.

- Test the clutch pedal feel. It should be firm and consistent.

- Adjust the pushrod length as needed to achieve the desired clutch engagement point.

- Verify that the clutch fully disengages, allowing for smooth shifting.

Troubleshooting Common Issues

- Spongy Pedal Feel: Indicates air in the system. Re-bleed the clutch system thoroughly. Check for leaks in the lines and connections.

- Stiff Pedal: May indicate an incorrect bore size (too large) or an improperly adjusted pushrod. Re-evaluate the bore size and adjust the pushrod length.

- Clutch Drag (Difficulty Shifting): May indicate insufficient clutch disengagement due to air in the system, a faulty slave cylinder, or an improperly adjusted pushrod. Bleed the system, inspect the slave cylinder, and adjust the pushrod.

- Leaks: Check all connections and fittings for tightness. Replace damaged crush washers or lines.

Conclusion

Upgrading to a Wilwood clutch master cylinder on a 240SX offers significant improvements in pedal feel, durability, and performance. By carefully selecting the appropriate bore size, following the installation instructions, and properly bleeding the system, you can enhance your driving experience and ensure reliable clutch operation, even with high-performance clutches. Always prioritize safety and consult with experienced professionals if you are unsure about any aspect of the installation process. A properly installed Wilwood master cylinder is a worthwhile investment for any 240SX owner looking to maximize the performance and reliability of their vehicle.