350z Differential Swap Technical Requirements And Modifications

The Nissan 350Z, a modern classic in the world of performance coupes, offers a rewarding driving experience right out of the box. However, for those seeking enhanced performance, particularly in terms of acceleration and traction, a differential swap is a common and effective modification. This article will delve into the technical requirements and potential modifications associated with swapping the differential on a 350Z, providing a comprehensive overview for the technically inclined enthusiast.

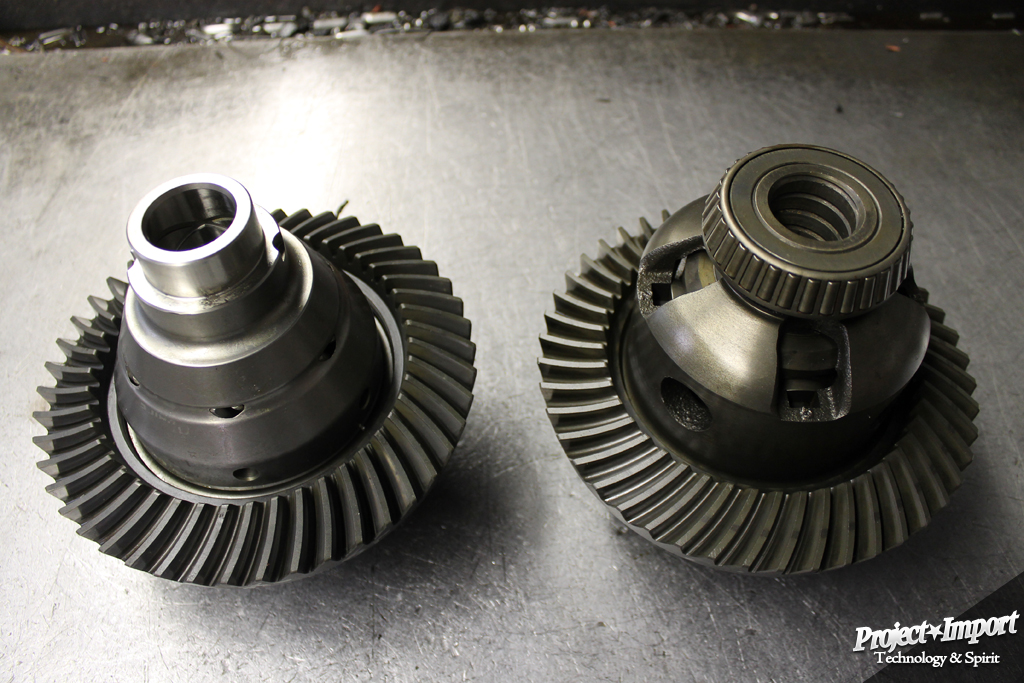

Understanding the 350Z Differential

Before diving into the swap itself, it's crucial to understand the function of the differential and the different types available for the 350Z. The differential's primary role is to allow the wheels on the same axle to rotate at different speeds, which is essential when cornering. Without it, the inner wheel would need to spin at the same rate as the outer wheel, causing tire slippage and making turning difficult.

The 350Z came equipped with different differential options depending on the model year and trim level. The most common are:

- Open Differential: This is the standard differential found in most base model 350Zs. It allows for unrestricted speed differences between the wheels. However, its main drawback is that if one wheel loses traction (e.g., due to ice or being lifted off the ground), all the power will be sent to that wheel, leaving the other wheel with no torque.

- Viscous Limited-Slip Differential (VLSD): Found in some higher trim levels, the VLSD uses a viscous fluid coupling to transfer torque to the wheel with more traction when one wheel starts to slip. The effectiveness of a VLSD diminishes with age as the fluid degrades.

- Electronic Limited-Slip Differential (eLSD): Later model 350Zs might feature eLSD, which use electronic sensors and actuators to apply braking force to the spinning wheel, forcing torque to the wheel with grip.

For performance enthusiasts, upgrading to a stronger or more effective Limited-Slip Differential (LSD) is a popular choice. Common upgrade options include:

- Clutch-Type LSD: These use a stack of clutch plates to limit wheel spin. They offer a more aggressive and predictable lock-up compared to VLSDs, making them suitable for track use.

- Torsen LSD: Torsen differentials (torque-sensing) use gears to transfer torque from the slipping wheel to the wheel with more grip. They are generally smoother and quieter than clutch-type LSDs, making them a good option for street and occasional track use.

- Spool: A spool effectively locks both axles together, eliminating any differential action. This is primarily used in drag racing applications where maximum traction in a straight line is desired, but it is not recommended for street driving due to its impact on handling.

Technical Requirements for a Differential Swap

Performing a differential swap on a 350Z requires a reasonable degree of mechanical skill, proper tools, and a safe working environment. Here's a breakdown of the essential requirements:

Tools and Equipment:

- Jack and Jack Stands: Essential for safely lifting and supporting the vehicle. Use sturdy jack stands rated for the weight of the car.

- Wheel Chocks: To prevent the car from rolling while lifted.

- Socket Set: Including metric sockets and extensions. A breaker bar is highly recommended for stubborn bolts. Deep sockets are often needed.

- Wrench Set: Covering a range of metric sizes.

- Torque Wrench: Crucial for properly tightening bolts to the manufacturer's specifications.

- Impact Wrench (Optional but Recommended): Can significantly speed up the removal of stubborn bolts.

- Drain Pan: To catch the old differential fluid.

- Fluid Pump: For filling the new differential with fluid.

- Punch and Hammer: For removing stubborn axles.

- Pry Bar: Useful for separating components.

- Penetrating Oil: To loosen rusty bolts.

- Gloves and Eye Protection: For safety.

- Shop Rags: For cleaning up spills.

Parts and Materials:

- Replacement Differential: The chosen LSD or differential assembly. Ensure it's compatible with your 350Z model year and trim.

- Differential Fluid: Use the correct type and weight specified by the manufacturer of the new differential. Different LSDs require different fluids (e.g., some clutch-type LSDs require friction modifiers).

- Differential Seals: Consider replacing the differential seals (pinion seal and axle seals) to prevent leaks.

- New Bolts (Optional): Replacing bolts that have been tightened and loosened repeatedly is good practice.

- Threadlocker (e.g., Loctite): For securing certain bolts.

Procedure:

- Preparation: Safely lift the vehicle and secure it on jack stands. Disconnect the negative battery terminal.

- Draining the Old Differential Fluid: Locate the drain plug on the differential housing and remove it, allowing the old fluid to drain completely.

- Removing the Axles: Disconnect the axles from the differential. This usually involves removing bolts holding the axles to the differential flanges. Be careful not to damage the axle seals during removal. Sometimes a punch and hammer are needed to gently persuade them out.

- Removing the Driveshaft: Disconnect the driveshaft from the differential. Mark the orientation of the driveshaft flange to the differential flange to ensure proper reinstallation and minimize vibration.

- Removing the Differential Housing: Unbolt the differential housing from the subframe. This can be a heavy and awkward piece, so have a plan for safely lowering it to the ground.

- Installing the New Differential: Carefully lift the new differential into position and bolt it to the subframe. Torque the bolts to the manufacturer's specifications.

- Reinstalling the Driveshaft and Axles: Reconnect the driveshaft and axles to the differential. Ensure the driveshaft is aligned correctly based on your earlier markings. Torque all bolts to the manufacturer's specifications.

- Filling the Differential with Fluid: Locate the fill plug on the differential housing and fill the differential with the correct type and amount of fluid.

- Final Checks: Double-check all bolts and connections. Ensure there are no leaks.

- Lowering the Vehicle: Carefully lower the vehicle back to the ground.

- Test Drive: Perform a short test drive to check for any unusual noises or vibrations. Start slowly and gradually increase speed.

Potential Modifications and Considerations

While a differential swap is a relatively straightforward procedure, there are several potential modifications and considerations to keep in mind:

Gear Ratio:

The gear ratio of the differential affects the car's acceleration and top speed. A shorter gear ratio (e.g., 4.08) will provide quicker acceleration but lower top speed, while a taller gear ratio (e.g., 3.54) will provide slower acceleration but higher top speed. When swapping differentials, consider whether you want to change the gear ratio to suit your driving style and needs.

Axle Upgrades:

If you are significantly increasing the power output of your 350Z, you may want to consider upgrading the axles to handle the increased torque. The stock axles can be a weak point, especially with an aggressive LSD and increased horsepower. Upgraded axles are typically made from stronger materials and are designed to withstand higher loads.

Subframe Bushings:

While you have the differential out, it's a good opportunity to inspect the subframe bushings. Worn or damaged bushings can contribute to wheel hop and poor handling. Consider replacing them with polyurethane bushings for improved performance and durability. Keep in mind that polyurethane bushings can transmit more NVH (noise, vibration, and harshness) into the cabin.

Driveshaft Upgrades:

Similar to the axles, the driveshaft can also be a weak point in high-horsepower applications. Consider upgrading to a stronger driveshaft, especially if you are experiencing vibrations or suspect that the stock driveshaft is nearing its limit.

Break-In Procedure:

For new LSDs, especially clutch-type units, a proper break-in procedure is crucial for ensuring optimal performance and longevity. Follow the manufacturer's instructions for the break-in procedure, which typically involves driving the car gently for a certain number of miles and then changing the differential fluid.

Fluid Changes:

Regular differential fluid changes are essential for maintaining the health of the differential. Follow the manufacturer's recommended fluid change interval and use the correct type of fluid. Inspect the fluid for any signs of metal shavings or contamination, which could indicate a problem with the differential.

Conclusion

A differential swap is a valuable modification for improving the performance and handling of a Nissan 350Z. By understanding the different types of differentials, the technical requirements of the swap, and the potential modifications, you can make an informed decision and achieve the desired results. Remember to prioritize safety, use the correct tools and procedures, and consult with a qualified mechanic if you are unsure about any aspect of the process. With careful planning and execution, a differential swap can transform your 350Z into an even more enjoyable and capable performance machine.