97 Nissan Pickup Swirl Control Valve

The 97 Nissan Pickup, a reliable workhorse, often goes unnoticed for its subtle yet ingenious engineering. Among these under-appreciated features is the swirl control valve, a component designed to enhance combustion efficiency and reduce emissions, especially during cold starts and low-load conditions. While not unique to this model, its implementation and function provide a fascinating case study in automotive design.

The Need for Swirl: A Primer on Combustion

To fully understand the swirl control valve, we must first delve into the principles of internal combustion. A gasoline engine operates by mixing air and fuel, compressing the mixture, and igniting it to generate power. The efficiency of this process hinges on how thoroughly the air and fuel are mixed. Incomplete mixing results in pockets of unburnt fuel, leading to wasted energy, increased emissions (particularly hydrocarbons and carbon monoxide), and reduced performance.

Swirl, in this context, refers to a rotary motion imparted to the air-fuel mixture within the combustion chamber. This swirling action promotes better mixing, ensuring that more of the fuel comes into contact with oxygen, leading to a more complete and efficient burn. Different engine designs employ various methods to create swirl, from intake port shapes to strategically placed deflectors. The Nissan Pickup, in certain engine configurations (primarily the KA24E 2.4L engine), uses a swirl control valve to achieve this effect.

The 97 Nissan Pickup Swirl Control Valve: Design and Operation

The swirl control valve, in its essence, is a butterfly valve located within the intake manifold. Its purpose is to selectively restrict airflow into one of the two intake ports leading to each cylinder. By partially blocking one port, the majority of the incoming air is forced through the other port at a higher velocity. This creates a swirling motion as the air enters the combustion chamber.

Component Breakdown:

- Valve Body: This houses the butterfly valve and is typically cast aluminum, designed to withstand the temperatures and pressures within the intake manifold.

- Butterfly Valve: A flat, circular plate that rotates to control airflow. Its edges are carefully machined to minimize air leakage when closed.

- Actuator: This is the mechanism that controls the valve's position. In the 97 Nissan Pickup, this is usually a vacuum-operated actuator. A vacuum line connects the actuator to a source of vacuum in the engine (often the throttle body).

- Linkage: A series of levers and rods that connect the actuator to the butterfly valve, translating the actuator's linear motion into the valve's rotational motion.

- Vacuum Lines: These hoses deliver vacuum pressure to the actuator, causing it to open or close the valve.

Operational Sequence:

The swirl control valve's operation is typically tied to engine speed and load. Here's a simplified explanation of how it works:

- Cold Start/Low Load: When the engine is cold or operating under light load (e.g., idling or cruising at low speeds), the ECU (Engine Control Unit) signals a solenoid valve (often referred to as a vacuum switching valve, or VSV) to allow vacuum to reach the swirl control valve actuator. This vacuum pressure pulls the actuator, which in turn closes the butterfly valve partially blocking one intake port. The resulting high-velocity airflow creates strong swirl within the cylinder, promoting thorough air-fuel mixing and efficient combustion. This is especially crucial during cold starts when fuel atomization is poorer.

- Warm Engine/Higher Load: As the engine warms up and the load increases (e.g., during acceleration or climbing a hill), the ECU de-energizes the solenoid valve. This cuts off the vacuum supply to the swirl control valve actuator. A spring within the actuator then forces the butterfly valve to open fully. With both intake ports now unobstructed, airflow is maximized, providing ample air for higher power output. The swirl effect is reduced, but at higher engine speeds and loads, the inherent turbulence within the cylinder is usually sufficient for adequate air-fuel mixing.

The specific parameters that trigger the swirl control valve's operation (engine temperature, engine speed, throttle position) are programmed into the ECU and may vary slightly depending on the exact engine configuration and model year.

Troubleshooting and Maintenance

Like any mechanical component, the swirl control valve can be susceptible to failure. Common problems include:

- Vacuum Leaks: Cracked or disconnected vacuum lines can prevent the actuator from operating correctly. This can result in the valve being stuck open or closed, leading to poor engine performance or increased emissions. Inspect all vacuum lines connected to the swirl control valve and the VSV for cracks or leaks. Replace any damaged hoses.

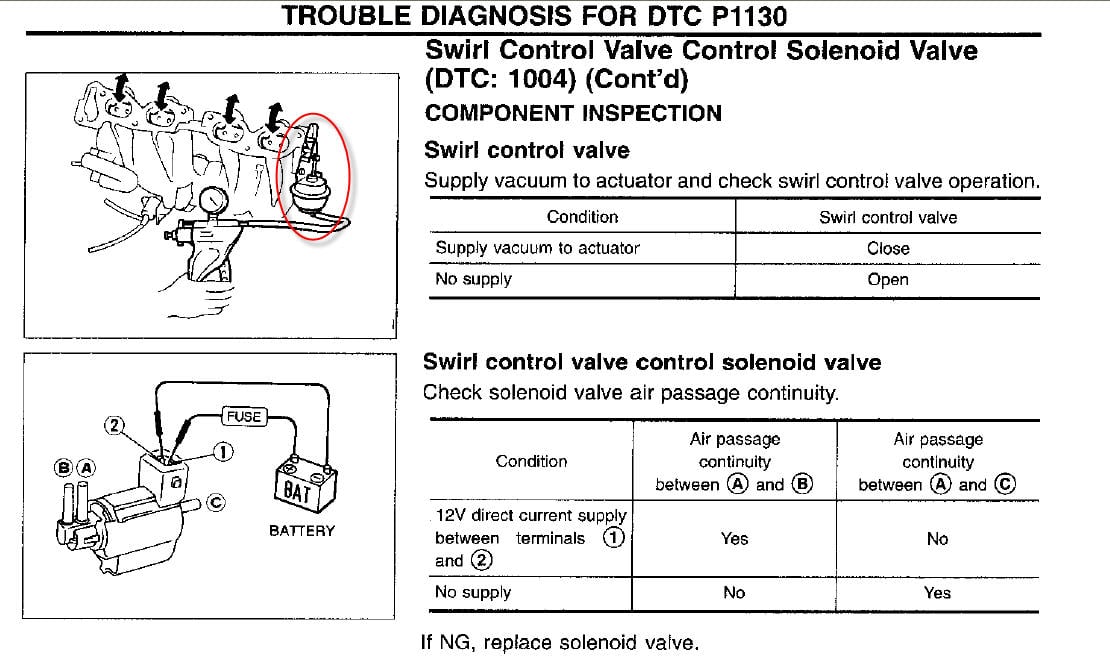

- Actuator Failure: The actuator itself can fail due to internal diaphragm rupture or corrosion. You can test the actuator by applying vacuum directly to the vacuum port and observing whether the linkage moves. If the actuator doesn't hold vacuum or the linkage doesn't move smoothly, it needs to be replaced.

- Valve Sticking: Carbon buildup or corrosion can cause the butterfly valve to stick in the open or closed position. This can be difficult to diagnose without removing the intake manifold and inspecting the valve directly. Cleaning the valve with carburetor cleaner may help, but if the valve is severely corroded or damaged, it may need to be replaced.

- VSV Malfunction: The vacuum switching valve (VSV) that controls the vacuum supply to the actuator can also fail. You can test the VSV using a multimeter to check for continuity. You should also be able to hear a clicking sound when the VSV is energized. If the VSV is not functioning correctly, it needs to be replaced.

Symptoms of a malfunctioning swirl control valve can include:

- Poor cold starting.

- Reduced fuel economy.

- Rough idling.

- Increased emissions (especially during cold starts).

- Hesitation during acceleration.

- Diagnostic trouble codes (DTCs) related to intake air or fuel trim (though these are not always specific to the swirl control valve).

Regular inspection of the vacuum lines and actuator is recommended as part of routine maintenance. While not a common maintenance item requiring frequent attention, addressing any issues promptly can prevent more serious engine problems down the road. Disconnecting the negative battery cable before working on any vacuum lines or electrical components is always a good safety practice.

The Swirl Control Valve in the Broader Automotive Context

The 97 Nissan Pickup's swirl control valve represents a relatively simple and effective approach to enhancing combustion efficiency. Modern engines often employ more sophisticated technologies, such as variable intake manifolds with electronically controlled flaps, to achieve similar results. These systems offer finer control over airflow and swirl, allowing for optimization across a wider range of engine operating conditions.

However, the fundamental principle remains the same: creating controlled turbulence within the combustion chamber to improve air-fuel mixing and combustion efficiency. Understanding the swirl control valve in the 97 Nissan Pickup provides valuable insight into the broader challenges of internal combustion engine design and the constant pursuit of improved efficiency and reduced emissions. It's a testament to the ingenuity of automotive engineers in finding practical and cost-effective solutions to complex problems.

While perhaps not the flashiest feature, the swirl control valve plays a crucial role in the overall performance and emissions characteristics of the 97 Nissan Pickup. By understanding its design, operation, and potential failure points, enthusiasts and amateur engineers alike can gain a deeper appreciation for the intricate workings of this reliable vehicle and the engineering principles that underpin it.