A Comprehensive Torque Specification Chart For The Nissan 240sx

The Nissan 240SX, a darling of the drifting and tuning scenes, demands precise maintenance and modification to perform optimally and reliably. A critical aspect of this is understanding and adhering to proper torque specifications. Torque, in simple terms, is a rotational force. Tightening a bolt or nut to the correct torque value ensures that the fastener provides the necessary clamping force to hold components together securely, without being overstressed, which can lead to failure. This article provides a comprehensive guide to torque specifications for various components of the Nissan 240SX, applicable to both the S13 (1989-1994) and S14 (1995-1998) models, focusing on common areas of interest for enthusiasts.

Understanding Torque and Measurement Units

Before diving into the specific torque values, it’s essential to understand the units of measurement commonly used. Torque is typically expressed in foot-pounds (ft-lbs) or Newton-meters (Nm). In this guide, we'll primarily use foot-pounds, with conversions to Newton-meters provided for reference. Remember that using the correct torque wrench and calibrating it regularly is vital for accurate torque application. Using an incorrect torque wrench or an uncalibrated one can lead to undertightening or overtightening, both of which can have severe consequences. A conversion factor to keep in mind is approximately 1 ft-lb equals 1.356 Nm.

Engine Torque Specifications

The engine is the heart of the 240SX, and proper torque application is crucial for its longevity and performance. These specifications are generally applicable to the KA24E (single overhead cam) and KA24DE (dual overhead cam) engines, though slight variations might exist based on year and specific sub-model. Always consult the factory service manual (FSM) for the most accurate information for your specific vehicle.

Cylinder Head

The cylinder head is a critical component, and the torque sequence and values are paramount. Improper tightening can lead to head gasket failure, coolant leaks, and even engine damage. Always use new head bolts as they are torque-to-yield bolts. These bolts stretch upon tightening, and re-using them can result in improper clamping force.

KA24E: Typically tightened in three stages: 22 ft-lbs, 43 ft-lbs, then an additional 90-degree turn. Always follow the specified torque sequence, usually from the center outwards in a crisscross pattern.

KA24DE: Follow a similar multi-stage approach. Consult the FSM for the exact torque values and final angle tightening, as they can vary slightly. A common sequence is 25 ft-lbs, then 51 ft-lbs, followed by a final 90-degree turn.

Main Bearing Caps

The main bearing caps secure the crankshaft in place. Tightening them correctly is essential for proper crankshaft rotation and bearing life.

KA24E/KA24DE: 33-36 ft-lbs. Again, follow the FSM's specified torque sequence. Lubricate the bolt threads and under the bolt heads with engine oil before tightening.

Connecting Rod Caps

Connecting rod caps secure the connecting rods to the crankshaft. Improper torque can lead to rod knock and engine failure.

KA24E/KA24DE: 18-22 ft-lbs, followed by a final 60-90 degree turn. Refer to the FSM for the precise angle specification. Ensure the connecting rod bearings are properly lubricated during installation.

Intake Manifold

KA24E/KA24DE: 11-15 ft-lbs. Tighten in a sequence that starts from the center and works outwards to ensure even clamping force and prevent leaks.

Exhaust Manifold

KA24E/KA24DE: 25-32 ft-lbs. Similar to the intake manifold, use a center-outward tightening sequence. Check for exhaust leaks after installation.

Valve Cover

KA24E/KA24DE: 3-5 ft-lbs. These bolts are easily overtightened, which can damage the valve cover. Use a low-range torque wrench.

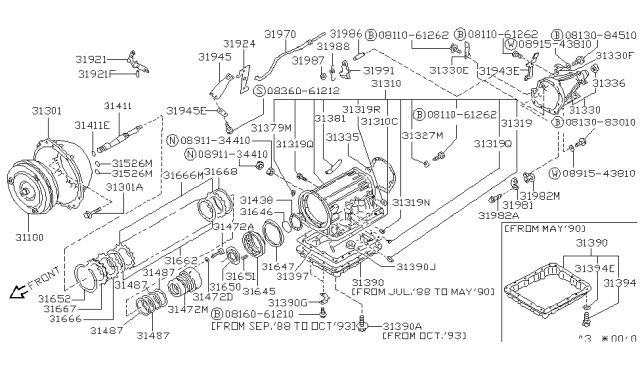

Drivetrain Torque Specifications

The drivetrain transfers power from the engine to the wheels. Proper torque is crucial for reliable operation of the transmission, differential, and related components.

Transmission Bellhousing Bolts

KA24E/KA24DE: 30-40 ft-lbs. These bolts secure the transmission to the engine.

Flywheel/Flexplate Bolts

These bolts attach the flywheel (manual transmission) or flexplate (automatic transmission) to the crankshaft. These are critical bolts and must be tightened correctly.

KA24E/KA24DE: 61-69 ft-lbs. Use new bolts and apply thread locker. Tighten in a star pattern.

Clutch Pressure Plate Bolts

KA24E/KA24DE: 14-18 ft-lbs. Tighten in a star pattern.

Differential Cover Bolts

S13/S14: 22-36 ft-lbs.

Driveshaft Bolts

S13/S14: 22-36 ft-lbs. It's recommended to use new bolts and apply thread locker.

Suspension and Chassis Torque Specifications

The suspension and chassis components ensure safe handling and vehicle stability. Proper torque is critical for these components.

Wheel Lug Nuts

S13/S14: 72-87 ft-lbs. Use a torque stick when using an impact gun to prevent overtightening. Always tighten lug nuts in a star pattern.

Strut Top Mount Bolts

S13/S14: Varies depending on aftermarket components. Consult the manufacturer's specifications. For OEM, typically 25-35 ft-lbs.

Lower Control Arm Bolts

S13/S14: Front: 80-95 ft-lbs. Rear: 60-75 ft-lbs (verify with FSM).

Tie Rod End Bolts

S13/S14: 36-51 ft-lbs.

Brake Caliper Bolts

S13/S14: Front: 25-36 ft-lbs. Rear: 17-25 ft-lbs (verify with FSM).

General Fastener Torque Guide (When Specific Torque is Unknown)

Sometimes, specific torque values are not readily available, especially for older vehicles or when dealing with non-original components. In such cases, a general fastener torque guide can be helpful. This guide is based on bolt size and grade (strength). However, this should be used as a last resort only. Always prioritize finding the specific torque specification in the factory service manual or from the component manufacturer.

Here’s a simplified table for Grade 8 bolts (SAE):

| Bolt Size | Torque (ft-lbs) |

|---|---|

| 1/4" | 9 |

| 5/16" | 19 |

| 3/8" | 33 |

| 7/16" | 54 |

| 1/2" | 83 |

Important Considerations:

- Bolt Grade: Identifying the bolt grade is crucial. Grade 8 bolts are stronger and require higher torque than lower-grade bolts.

- Thread Pitch: Fine threads typically require slightly less torque than coarse threads for the same bolt size and grade.

- Lubrication: Lubricated threads require less torque than dry threads to achieve the same clamping force. If the FSM specifies lubricated threads, apply a light coating of oil or anti-seize. If dry, clean the threads thoroughly.

- Material: The material being fastened also matters. Aluminum components are more susceptible to damage from overtightening than steel components.

Final Thoughts

This guide provides a comprehensive overview of torque specifications for the Nissan 240SX. However, it is not a substitute for the factory service manual (FSM). Always refer to the FSM for the most accurate and up-to-date information specific to your vehicle’s year and model. Using the correct torque specifications is essential for the longevity, reliability, and safety of your 240SX. Investing in a quality torque wrench and taking the time to understand these specifications will contribute significantly to the successful maintenance and modification of your vehicle. Happy wrenching!