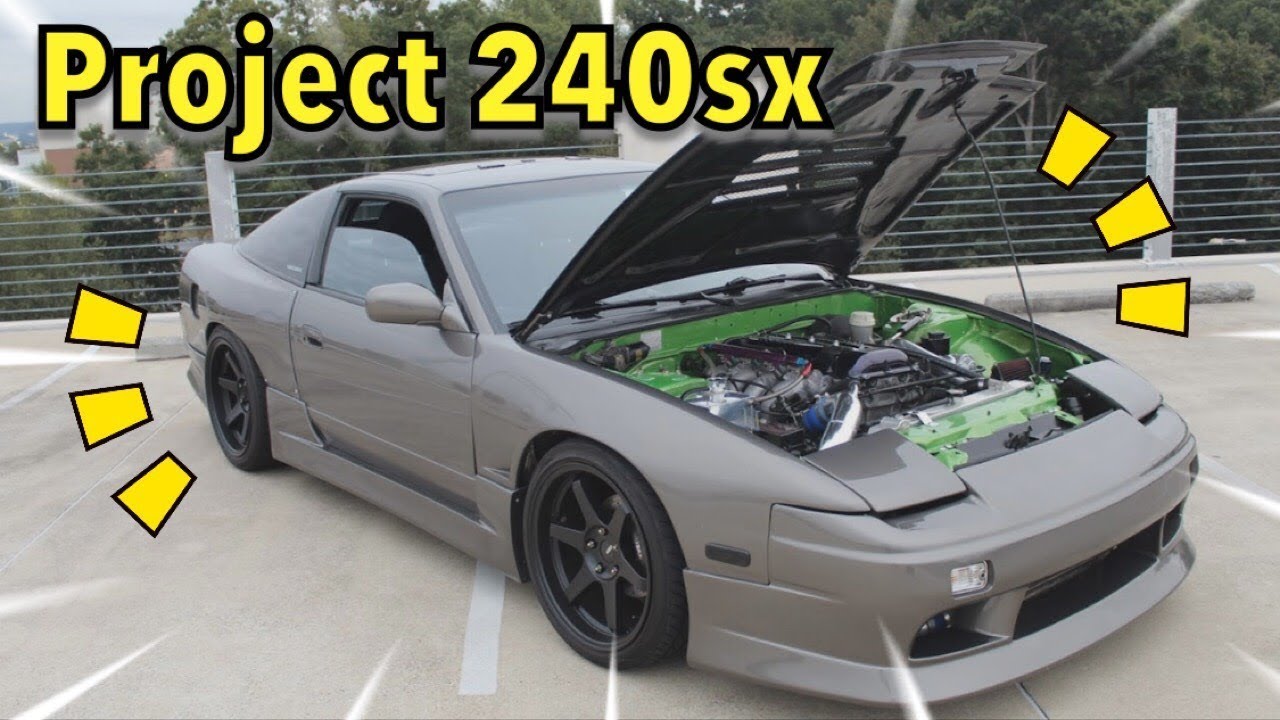

A Methodical Approach To Planning And Executing A Nissan 240sx Project Build

So, you're thinking about building a Nissan 240SX. Excellent choice! The 240SX, particularly the S13 and S14 chassis, offers a fantastic platform for a wide range of projects, from mild street builds to full-blown track machines. However, jumping in without a plan is a recipe for frustration and wasted money. This guide outlines a methodical approach to planning and executing your 240SX project, ensuring you stay on track and achieve your goals.

Phase 1: Define Your Project Goals & Budget

This is the most crucial step. Before you even touch a wrench, clearly define what you want to achieve with your 240SX. Ask yourself these questions:

- What is the intended use of the car? Daily driver? Weekend track toy? Drift car? Autocross competitor? Show car? A combination of these?

- What is your desired power level? A reliable, slightly improved engine? A fully built, high-horsepower monster?

- What is your desired handling characteristics? Comfortable street ride? Aggressive track handling? Drift-oriented suspension?

- What aesthetic are you aiming for? OEM restoration? Modern performance look? JDM style?

Be honest with yourself about your skill level and available time. Don't try to tackle a complex engine swap if you've never worked on an engine before. Consider the learning curve and whether you're willing to invest the time and effort required.

Setting a Realistic Budget

Once you have a clear vision, create a realistic budget. This is where many projects go wrong. Overestimating is better than underestimating. Research the cost of parts, labor (if you're outsourcing any work), tools, and unexpected expenses. Allocate funds for:

- The car itself: Factor in potential rust repair, existing damage, and the overall condition.

- Parts: Engine upgrades, suspension components, body kits, wheels, tires, etc.

- Labor: If you're not doing all the work yourself, get quotes from reputable shops.

- Tools: You'll likely need to acquire specialized tools.

- Fluids and Consumables: Oil, coolant, brake fluid, grease, etc.

- Unexpected Expenses: Always allocate 10-20% of your budget for unforeseen problems. Trust me, there *will* be unforeseen problems.

- Shipping costs and Taxes: These can quickly add up, especially with larger parts.

Use a spreadsheet to track your expenses and stick to your budget as closely as possible. Prioritize needs over wants and consider buying used parts (in good condition) to save money.

Phase 2: Research and Planning

Now that you have a clear goal and budget, it's time to dive into the details. Thorough research is crucial for avoiding costly mistakes and ensuring compatibility between components. Research:

- Engine Options: The stock KA24E/DE is a solid starting point, but many people opt for engine swaps like the SR20DET, RB25DET, 1JZ-GTE, 2JZ-GTE, or even LS swaps. Research the pros and cons of each option, including power potential, reliability, cost, and complexity.

- Suspension Systems: Coilovers, springs, shocks, sway bars, control arms – the options are endless. Understand how each component affects handling and choose a setup that matches your driving style and intended use. Consider adjustable components to fine-tune your suspension.

- Brake Upgrades: Improved braking is essential, especially with increased power. Research different brake rotor sizes, caliper options, and master cylinder upgrades.

- Differential and Drivetrain: A limited-slip differential (LSD) can significantly improve traction. Consider upgrading axles if you're increasing power substantially.

- ECU and Tuning: If you're modifying the engine, you'll need a way to manage it. Options include standalone ECUs, piggyback ECUs, and reflashing the stock ECU. Understand the tuning process and either learn to tune yourself or hire a qualified tuner. This is not an area to cut corners!

- Wiring Harnesses: Engine swaps often require custom wiring harnesses. Research reputable suppliers and understand the wiring process. Consider purchasing a pre-made harness for simplicity.

Read forums, watch YouTube videos, and talk to other 240SX owners. Learn from their experiences and avoid common pitfalls. Create a detailed parts list with part numbers, prices, and vendors. This will help you stay organized and track your progress.

Phase 3: Acquisition & Preparation

With your plan and budget in place, it's time to acquire the necessary parts and tools. Start by purchasing the core components, such as the engine, transmission, and suspension. Inspect all parts thoroughly before installing them. This includes:

- Checking for damage: Cracks, dents, corrosion, etc.

- Verifying part numbers: Ensure you have the correct parts.

- Cleaning and inspecting used parts: Replace worn or damaged components.

Preparing the Chassis

Before installing any new parts, prepare the chassis. This may involve:

- Rust Repair: Address any rust issues before they worsen. This is often the biggest challenge with older 240SXs. Welding skills or professional help may be required.

- Cleaning: Thoroughly clean the engine bay, interior, and undercarriage.

- Sound Deadening: Consider adding sound deadening material to reduce road noise.

- Wiring: Clean up and organize the existing wiring harness. Repair any damaged wires.

Take your time and do it right. A clean and well-prepared chassis will make the rest of the project much easier.

Phase 4: Installation & Fabrication

Now the fun begins! Start installing the new parts according to your plan. Follow manufacturer instructions carefully and double-check your work. If you're performing an engine swap, pay close attention to the wiring harness and fuel system. Take plenty of pictures and notes as you disassemble and reassemble parts. This will be invaluable if you run into problems later.

Fabrication

Many 240SX projects require some degree of fabrication. This may include:

- Welding: For rust repair, roll cage installation, or custom exhaust fabrication.

- Cutting and Grinding: For modifying body panels or creating custom brackets.

- Wiring: For creating custom wiring harnesses or adapting existing harnesses.

If you're not comfortable with fabrication, consider outsourcing this work to a qualified shop. Poorly executed fabrication can compromise the safety and reliability of your car.

Phase 5: Testing, Tuning, and Refinement

Once you've completed the installation, it's time to test and tune your car. Start with a thorough inspection to ensure everything is properly installed and connected. Then, perform a series of test drives to identify any problems. Address any issues before proceeding to tuning.

Tuning

If you've modified the engine, you'll need to tune the ECU to optimize performance and ensure reliability. This can be done on a dynamometer (dyno) by a qualified tuner. The tuner will adjust the fuel and ignition maps to maximize power while maintaining safe operating parameters. A proper tune is essential for preventing engine damage.

Refinement

After tuning, continue to refine your car based on your driving experience. This may involve adjusting the suspension settings, tweaking the alignment, or making minor modifications to improve performance or comfort. This iterative process of testing, tuning, and refinement is what separates a good build from a great one.

Phase 6: Enjoy Your Ride!

Finally, the moment you've been waiting for! Get out there and enjoy your newly built 240SX. But remember, a project car is never truly "finished." There will always be something to improve or modify. Keep learning, keep tinkering, and keep enjoying the process!