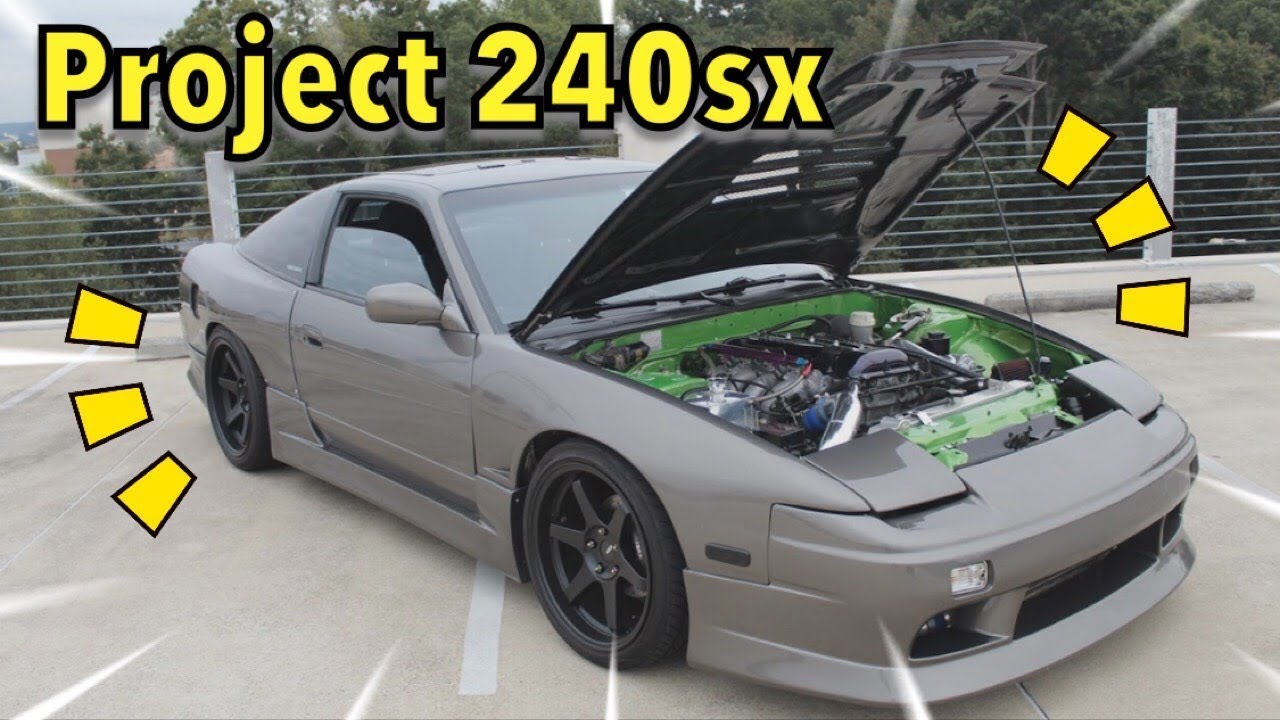

A Step-by-step Guide To Planning And Executing A 240sx Project Build

The Nissan 240SX, particularly the S13 and S14 generations, enjoys enduring popularity as a project car platform. Its lightweight chassis, rear-wheel-drive configuration, and readily available aftermarket support make it a prime candidate for modification, ranging from mild upgrades to complete overhauls. However, embarking on a 240SX project without a clear plan is a recipe for frustration, cost overruns, and potentially, an unfinished car. This guide outlines a methodical, step-by-step approach to planning and executing a successful 240SX build.

Phase 1: Defining the Project Scope

The first and most critical phase involves defining the project's scope. This determines the level of effort, budget, and ultimately, the car's intended purpose. Asking yourself these questions will help clarify your objectives:

1. Intended Use:

Is the 240SX intended for:

Daily Driving: Focus on reliability, comfort, and modest performance gains.

Track Days: Prioritize handling, braking, and engine power, with a focus on durability under demanding conditions.

Drifting: Emphasis on power delivery, suspension setup for controlled oversteer, and durability under high-stress maneuvers.

Drag Racing: Concentrate on maximizing horsepower and traction for straight-line acceleration.

Show Car: Aesthetics take precedence, with attention to detail in paint, bodywork, and interior modifications.

Realistically assess your driving style and needs. Building a drift car for daily commuting is impractical, just as building a show car for track days is likely to result in disappointment (and potential damage).

2. Budget Allocation:

Establish a realistic budget. 240SX projects are notorious for exceeding initial estimates. Break down the budget into key areas:

Acquisition Cost: The initial price of the 240SX.

Engine/Drivetrain: Costs associated with engine upgrades, swaps, transmission modifications, and differential work.

Suspension: Coilovers, sway bars, bushings, and other suspension components.

Brakes: Calipers, rotors, pads, and brake lines.

Wheels/Tires: Alloy wheels and performance tires.

Bodywork/Paint: Repairs, modifications, and paint job.

Interior: Seats, gauges, steering wheel, and other interior upgrades.

Electronics: Engine management system (EMS), gauges, and wiring.

Contingency: A buffer for unexpected expenses (aim for 10-20% of the total budget).

Research the cost of components before committing to a plan. Online forums, vendor websites, and performance shops are valuable resources. Be honest with yourself about your financial limitations. It's better to complete a well-executed, budget-conscious build than to leave a half-finished project languishing in the garage.

3. Skill Level and Resources:

Evaluate your mechanical skills and available tools. Be realistic about what you can accomplish yourself and what requires professional assistance. Consider:

Mechanical Experience: Can you confidently perform engine swaps, suspension installations, and wiring modifications?

Tools and Equipment: Do you have access to a well-equipped garage with essential tools such as a jack, stands, wrenches, sockets, and diagnostic equipment?

Time Commitment: Project builds require significant time and dedication. Factor in your work schedule, family obligations, and other commitments.

Don't be afraid to seek help from experienced friends, local mechanics, or performance shops. Knowing when to delegate tasks is crucial for a successful build.

Phase 2: Component Selection and Sourcing

With a clear project scope defined, the next phase involves selecting and sourcing components. Research is paramount to ensure compatibility, quality, and value.

1. Engine and Drivetrain:

The engine is the heart of the 240SX. Popular options include:

SR20DET: The factory engine, offering a good balance of power and reliability. Upgrades can significantly increase performance.

KA24DE: The naturally aspirated engine. Less powerful than the SR20DET but more affordable and reliable. A good option for budget builds or forced induction upgrades.

RB25DET/RB26DETT: Inline-six engines offering higher horsepower potential but requiring more extensive modifications.

LS V8: A popular swap for its high horsepower and readily available parts. Requires significant fabrication and chassis reinforcement.

Consider the engine's condition, provenance, and compatibility with the 240SX chassis. Thoroughly inspect used engines before purchasing. If opting for a swap, research the required mounting hardware, wiring harnesses, and other necessary components.

The transmission and differential should be selected to match the engine's power output and intended use. Upgrading to a stronger transmission and limited-slip differential (LSD) is recommended for high-performance applications.

2. Suspension and Brakes:

Upgrading the suspension enhances handling and responsiveness. Options include:

Coilovers: Adjustable ride height and damping for fine-tuning handling characteristics.

Sway Bars: Reduce body roll and improve cornering stability.

Bushings: Replace worn-out rubber bushings with polyurethane or spherical bearings for improved responsiveness.

Adjustable Arms: Allow for precise alignment adjustments to optimize handling.

Choose suspension components based on your intended use and budget. Quality coilovers are a worthwhile investment for track days and drifting.

Upgrading the brakes is crucial for safety and performance. Consider:

Larger Rotors and Calipers: Increase braking surface area and clamping force for improved stopping power.

Performance Brake Pads: Provide higher friction for better braking performance.

Stainless Steel Brake Lines: Reduce brake line expansion for a firmer pedal feel.

Ensure the brake upgrade is compatible with your wheel size and master cylinder. A brake bias adjuster can help fine-tune the front-to-rear braking balance.

3. Wheels and Tires:

Wheels and tires significantly impact handling, traction, and aesthetics. Choose wheels that are lightweight, strong, and appropriately sized for your suspension and brakes.

Select tires that match your intended use. Performance tires with a softer compound provide better grip for track days and drifting, while all-season tires offer better wet-weather performance and longevity.

4. Sourcing Parts:

Source parts from reputable vendors and suppliers. Consider:

Online Retailers: Offer a wide selection of parts and competitive prices.

Performance Shops: Provide expert advice and installation services.

Used Parts Market: A cost-effective option for certain components, but exercise caution and inspect parts thoroughly.

Compare prices and read reviews before purchasing. Don't compromise on quality to save a few dollars. Cheap parts often lead to problems down the road.

Phase 3: Execution and Assembly

With parts acquired, the execution phase begins. Follow these guidelines for a smooth and successful assembly:

1. Organization and Documentation:

Maintain a clean and organized workspace. Label and store parts carefully. Document your progress with photos and notes. This will be invaluable for troubleshooting and future reference.

2. Step-by-Step Installation:

Follow installation manuals and tutorials carefully. Don't rush. Double-check your work at each step. If unsure about a procedure, seek guidance from experienced individuals or consult online resources.

3. Testing and Tuning:

After assembly, thoroughly test all systems. Check for leaks, noises, and other abnormalities. Perform initial tuning on a dyno or with a professional tuner. Fine-tune the engine management system (EMS) to optimize performance and fuel efficiency.

4. Addressing Challenges:

Inevitably, challenges will arise. Don't get discouraged. Research solutions, seek advice, and be patient. A methodical approach is key to overcoming obstacles.

Phase 4: Refinement and Maintenance

Once the 240SX is running and driving, the final phase involves refinement and maintenance. This includes:

1. Addressing Issues:

Identify and address any remaining issues. This may involve further tuning, suspension adjustments, or component replacements.

2. Regular Maintenance:

Perform regular maintenance to keep the 240SX in top condition. This includes oil changes, fluid flushes, brake inspections, and tire rotations.

3. Continuous Improvement:

The 240SX project is never truly "finished." Continuously evaluate your car's performance and identify areas for improvement. Embrace the journey of learning and refining your build.

Building a 240SX is a rewarding but challenging endeavor. By following a structured plan, selecting quality components, and dedicating time and effort, you can transform a stock 240SX into a personalized machine that reflects your vision and passion.