Air Compressor For 2017 Nissan Altima

Delving into the Air Conditioning System: The Air Compressor in Your 2017 Nissan Altima

The air conditioning system in your 2017 Nissan Altima, like in most modern vehicles, is a complex yet crucial component for passenger comfort. At its heart lies the air compressor, a mechanical pump responsible for circulating the refrigerant that cools the air entering the cabin. Understanding the compressor's function, operation, and potential issues can empower you to diagnose problems, potentially saving time and money on repairs.

The Role of the Air Compressor in the A/C Cycle

Before diving into the specifics of the 2017 Altima's compressor, it's essential to understand the broader air conditioning cycle. The system operates based on the principles of thermodynamics, leveraging refrigerant's phase changes (liquid to gas and back) to absorb and release heat. The major components, besides the compressor, include:

- Evaporator: Located inside the cabin, usually behind the dashboard. It absorbs heat from the cabin air, causing the refrigerant to evaporate into a low-pressure gas.

- Condenser: Located in front of the radiator, it releases the heat absorbed from the cabin into the outside air, causing the refrigerant gas to condense back into a high-pressure liquid.

- Expansion Valve (or Orifice Tube): Controls the flow of refrigerant into the evaporator, reducing the pressure and temperature.

- Receiver Drier (or Accumulator): Filters contaminants and moisture from the refrigerant.

The compressor is the engine of this cycle. It performs the crucial task of increasing the pressure and temperature of the refrigerant gas coming from the evaporator. This high-pressure, high-temperature gas is then pushed to the condenser, where heat is expelled.

The 2017 Nissan Altima's Air Compressor: Type and Operation

The 2017 Nissan Altima typically employs a scroll-type compressor, though some model years may use a variable displacement swashplate compressor. Scroll compressors are generally favored for their efficiency, quiet operation, and relatively compact size. Understanding the type is essential for diagnosis and repair.

Scroll compressors function using two interleaved spiral scrolls, one fixed and one orbiting. As the orbiting scroll moves within the fixed scroll, it creates pockets of decreasing volume, compressing the refrigerant gas. This continuous compression process results in a steady flow of high-pressure refrigerant. These compressors are known for their smooth operation and reduced pulsation compared to older piston-type compressors.

Variable Displacement compressors use a swashplate mechanism to control the stroke length of the pistons. This allows the compressor to adjust its output based on the cooling demand, improving fuel efficiency. While robust, they can be more complex to diagnose and repair. If your Altima has automatic climate control, it is more likely to have a variable displacement compressor.

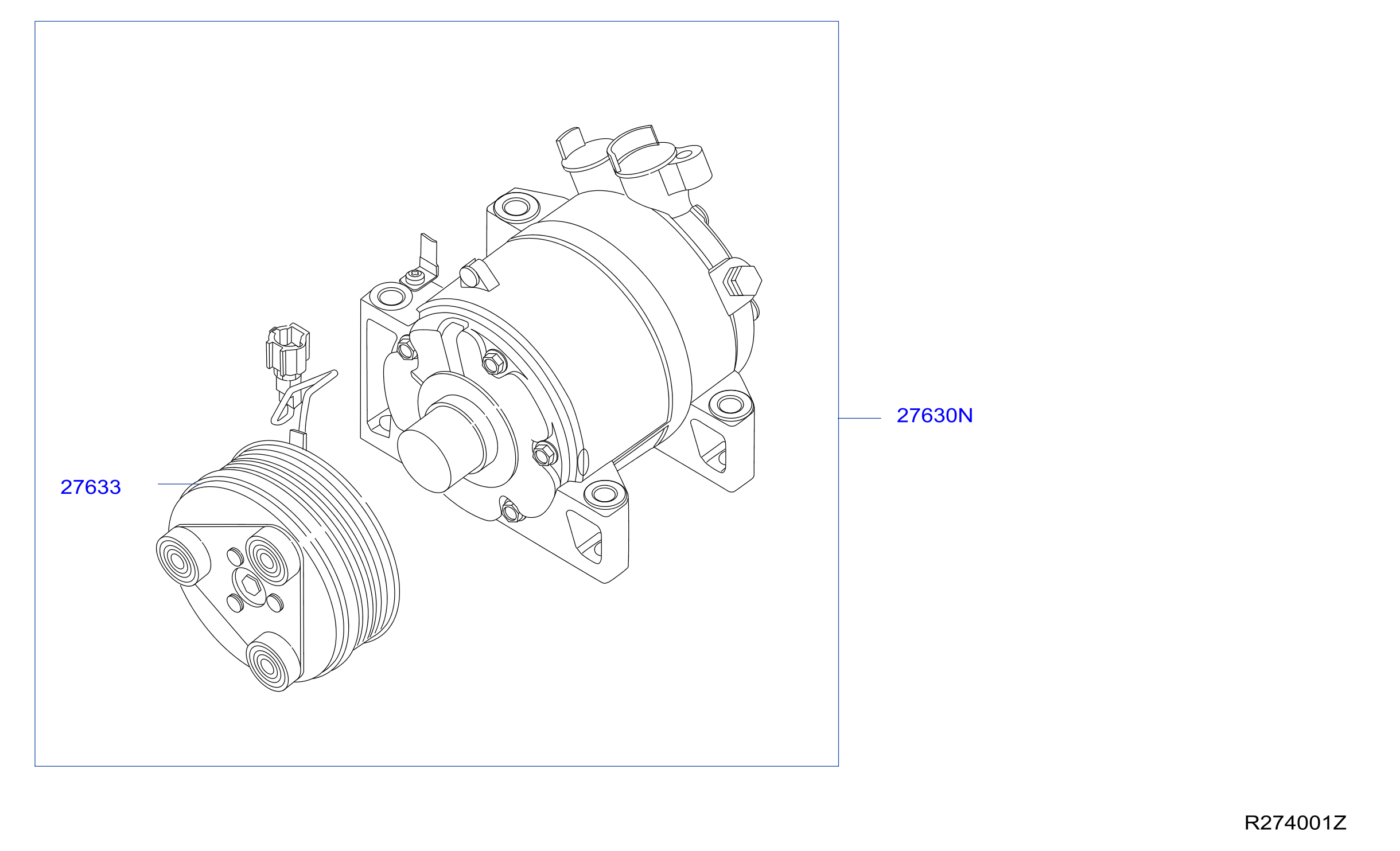

In either case, the compressor is driven by the engine via a belt connected to the crankshaft. An electromagnetic clutch engages or disengages the compressor, allowing the A/C system to be turned on or off. When the A/C is engaged, the clutch locks the compressor pulley to the compressor shaft, causing the compressor to start pumping refrigerant.

Key Components & Control Mechanisms

Beyond the compressor itself, several related components are critical to its operation:

- A/C Clutch: An electromagnetic clutch engages the compressor pulley to the compressor shaft when the A/C system is activated. A worn clutch or insufficient air gap can cause the compressor to intermittently engage or fail to engage altogether. The clutch is energized by a relay controlled by the A/C switch and various safety sensors.

- Pressure Switches: These sensors monitor the refrigerant pressure in the system. Low-pressure switches protect the compressor from running dry (which can cause damage), while high-pressure switches prevent over-pressurization, which could lead to component failure. These switches send signals to the engine control unit (ECU), which can disengage the A/C clutch if pressure levels are outside the acceptable range.

- Refrigerant: The type and charge level of the refrigerant are critical. The 2017 Altima typically uses R-134a refrigerant, though some newer models may use R-1234yf. Improper refrigerant type or insufficient charge can significantly impact the A/C system's performance and potentially damage the compressor.

- Compressor Control Valve (Variable Displacement Compressors): If equipped with a variable displacement compressor, a control valve regulates the amount of refrigerant being compressed. This valve responds to signals from the climate control system, adjusting the compressor's output to match the cooling demand. A malfunctioning control valve can cause inconsistent cooling or complete A/C failure.

Common Air Compressor Problems in the 2017 Altima

Several issues can plague the Altima's air compressor. Recognizing these problems early can prevent more extensive damage.

- Compressor Clutch Failure: A worn or damaged clutch is a common problem. Symptoms include a squealing noise when the A/C is engaged, intermittent cooling, or complete A/C failure. A visual inspection can often reveal a worn clutch plate or excessive air gap.

- Internal Compressor Failure: Internal wear or damage can cause the compressor to seize or become inefficient. Symptoms include unusual noises (grinding or knocking) coming from the compressor, reduced cooling performance, and metal particles circulating in the refrigerant system. In this case, replacement is typically necessary.

- Refrigerant Leaks: Low refrigerant levels can prevent the compressor from engaging or cause it to run inefficiently. Leaks can occur at various points in the system, including the compressor seals, hoses, and fittings.

- Contamination: Dirt, debris, or moisture in the refrigerant system can damage the compressor's internal components. A clogged receiver drier can also contribute to compressor failure. Proper system flushing and vacuuming are essential when replacing a compressor.

- Electrical Issues: Problems with the A/C clutch relay, pressure switches, or wiring can prevent the compressor from engaging.

Troubleshooting & Diagnostics

Diagnosing A/C compressor issues requires a systematic approach:

- Visual Inspection: Check the compressor clutch for damage, wear, and proper air gap. Examine the compressor housing for signs of leaks or damage. Inspect the belt for wear or slippage.

- Pressure Testing: Use a manifold gauge set to measure the high-side and low-side pressures in the system. Abnormal pressure readings can indicate compressor problems, refrigerant leaks, or blockages in the system.

- Clutch Engagement Test: Verify that the A/C clutch is receiving power when the A/C is engaged. Use a multimeter to check for voltage at the clutch connector.

- Scan Tool Diagnostics: Use an OBD-II scan tool to check for A/C system-related trouble codes. These codes can provide valuable clues about the nature of the problem.

- Refrigerant Level Check: While pressure readings can be helpful, it's important to ensure the system has the correct refrigerant charge. If a leak is suspected, use a leak detector to pinpoint the source.

Repair & Replacement

Repairing or replacing an air compressor typically requires specialized tools and knowledge. Always consult a qualified automotive technician for complex A/C repairs. Before replacing a compressor, it's crucial to:

Identify the root cause of the compressor failure. Replacing the compressor without addressing underlying issues, such as refrigerant leaks or contamination, will likely lead to premature failure of the new compressor.

The replacement process generally involves:

- Recovering the remaining refrigerant (using specialized equipment).

- Disconnecting the A/C lines and electrical connectors.

- Removing the old compressor.

- Flushing the A/C system to remove contaminants.

- Replacing the receiver drier (or accumulator).

- Installing the new compressor.

- Evacuating the system to remove air and moisture.

- Recharging the system with the correct type and amount of refrigerant.

Choosing a high-quality replacement compressor from a reputable brand is essential for ensuring long-term reliability. Consider purchasing a new compressor rather than a rebuilt unit, as rebuilt compressors may have a shorter lifespan.

Preventative Maintenance

While A/C system issues can arise unexpectedly, preventative maintenance can help prolong the life of your Altima's air compressor:

- Regular A/C System Checks: Have the A/C system inspected by a qualified technician at least once a year.

- Refrigerant Recharge: If the A/C system is not cooling as well as it used to, consider having the refrigerant recharged.

- Replace Air Filter Regularly: A clean cabin air filter ensures proper airflow to the evaporator, which can improve A/C performance.

- Run the A/C Periodically: Even during the winter months, running the A/C for a few minutes each week can help lubricate the compressor and prevent seals from drying out.

By understanding the function, operation, and potential problems of the air compressor in your 2017 Nissan Altima, you can be better equipped to diagnose issues and make informed decisions about repair and maintenance. Remember that A/C system repairs can be complex, so consulting a qualified technician is always recommended.