Battery Group Size Specifications And Electrical System Analysis

Understanding your vehicle's battery and electrical system is crucial for ensuring its reliable operation. Two key aspects of this understanding are the battery group size and a thorough electrical system analysis. This article will guide you through these important concepts, helping you make informed decisions about your vehicle's power source.

What is Battery Group Size?

Battery group size refers to a standardized classification system for automotive batteries. This system, established by the Battery Council International (BCI), defines a battery's physical dimensions (length, width, and height), terminal type, and general performance characteristics. It's essentially a code that helps you quickly identify a battery that will physically fit in your vehicle's battery tray and provide the necessary power.

Think of it like shoe sizes – a size 10 from one brand is generally the same size 10 from another. Similarly, a Group 24 battery should generally have the same dimensions and electrical characteristics as another Group 24 battery.

Why is Battery Group Size Important?

Choosing the correct battery group size is paramount for several reasons:

- Fitment: The most obvious reason is physical fit. A battery that is too large will not fit in the battery tray, and a battery that is too small might not be securely held in place. A loose battery can vibrate, leading to premature failure.

- Terminal Compatibility: Different battery group sizes can have different terminal types and orientations. Using the wrong group size could prevent you from connecting the battery cables properly.

- Cold Cranking Amps (CCA): Battery group size is often correlated with CCA, which is a measure of a battery's ability to start an engine in cold weather. Using a battery with insufficient CCA could lead to starting problems, especially in colder climates.

- Reserve Capacity (RC): Reserve capacity indicates how long a fully charged battery can power essential accessories if the alternator fails. Using a battery with insufficient RC could leave you stranded if your alternator malfunctions.

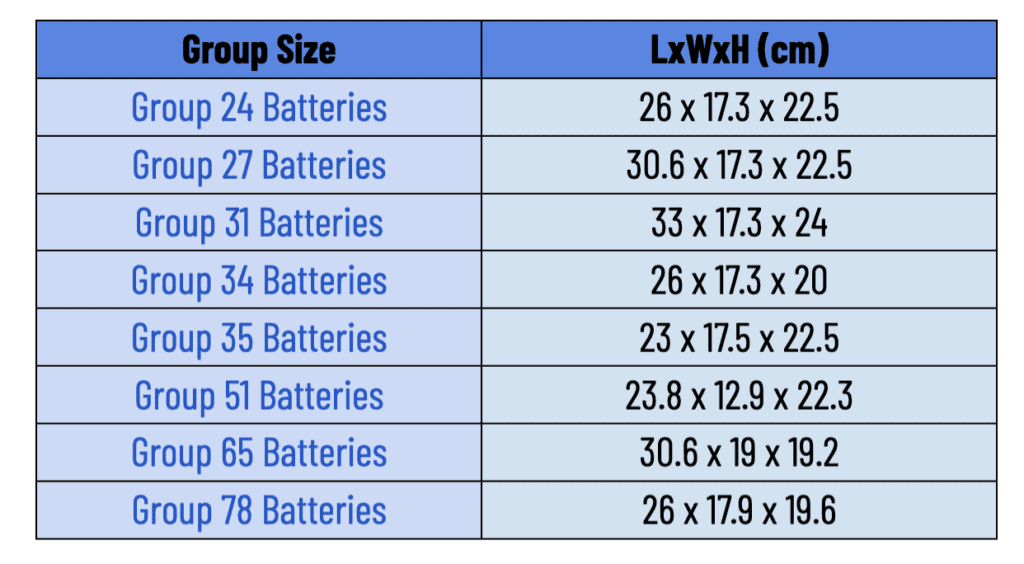

Common Battery Group Sizes

While there are numerous battery group sizes, some are more common than others. Here are a few examples:

- Group 24/24F: Often found in Japanese and some American vehicles.

- Group 27: Commonly used in trucks, SUVs, and marine applications due to their higher capacity.

- Group 34: Smaller than Group 24 and often used in vehicles with limited space.

- Group 35: Another common size for smaller vehicles, often Japanese imports.

- Group 65: Frequently found in Ford trucks and SUVs.

- Group 75: Often used in General Motors vehicles.

Note: This is not an exhaustive list, and the best way to determine the correct battery group size for your vehicle is to consult your owner's manual or use a battery size finder tool provided by reputable battery manufacturers (such as Optima, DieHard, or Interstate).

Finding the Right Battery Group Size

Here are several methods to determine the correct battery group size for your vehicle:

- Consult Your Owner's Manual: This is the most reliable source of information. The manual will specify the recommended battery group size for your vehicle.

- Check the Existing Battery: The battery group size is usually printed on the battery label.

- Use a Battery Size Finder Tool: Many battery manufacturers offer online tools that allow you to enter your vehicle's year, make, and model to find the correct battery group size.

- Consult a Professional: A mechanic or auto parts store employee can help you determine the correct battery group size for your vehicle.

Electrical System Analysis: Diagnosing Problems and Ensuring Optimal Performance

While the battery is a critical component, it's only one part of your vehicle's electrical system. A comprehensive electrical system analysis is essential for diagnosing problems and ensuring optimal performance. This involves testing various components and circuits to identify any faults or weaknesses.

Key Components of the Electrical System

Understanding the main components of your vehicle's electrical system is crucial for proper diagnosis:

- Battery: Provides the initial power to start the engine and operate accessories.

- Alternator: Recharges the battery while the engine is running and provides power to the vehicle's electrical systems.

- Starter: Cranks the engine to initiate combustion.

- Wiring Harness: A network of wires that connects all the electrical components.

- Fuses and Relays: Protect the electrical circuits from overloads and control the flow of electricity.

- Sensors: Monitor various parameters (temperature, pressure, etc.) and send signals to the engine control unit (ECU).

- ECU (Engine Control Unit): The "brain" of the engine, controlling various functions based on sensor inputs.

Common Electrical System Problems

Many issues can arise within a vehicle's electrical system. Here are some of the most common:

- Dead Battery: Caused by leaving lights on, a parasitic draw, or a faulty battery.

- Alternator Failure: Results in a dead battery and can cause the engine to stall.

- Starter Motor Failure: Prevents the engine from starting.

- Faulty Wiring: Can cause shorts, open circuits, and intermittent problems.

- Blown Fuses: Indicate an overload in a specific circuit.

- Faulty Sensors: Can lead to incorrect engine operation and poor fuel economy.

Performing an Electrical System Analysis

A proper electrical system analysis involves a series of tests to isolate and diagnose any issues. Here are some common procedures:

- Battery Load Test: Measures the battery's ability to deliver power under load.

- Alternator Output Test: Checks the alternator's charging voltage and amperage.

- Starter Draw Test: Measures the amount of current the starter motor draws during cranking.

- Voltage Drop Test: Identifies excessive resistance in electrical circuits.

- Continuity Test: Verifies the integrity of wiring and connections.

- Parasitic Draw Test: Detects excessive current drain when the vehicle is turned off.

- OBD-II Scan: Retrieves diagnostic trouble codes (DTCs) from the ECU.

Tools for Electrical System Analysis

Several specialized tools are required for performing a thorough electrical system analysis:

- Multimeter: Used to measure voltage, current, and resistance.

- Battery Load Tester: Applies a load to the battery and measures its voltage.

- Alternator Tester: Checks the alternator's output voltage and amperage.

- OBD-II Scanner: Reads diagnostic trouble codes (DTCs) from the ECU.

- Wiring Diagrams: Essential for tracing circuits and identifying components.

When to Seek Professional Help

While some basic electrical system tests can be performed by DIYers, it's often best to seek professional help from a qualified mechanic. If you're not comfortable working with electrical systems or if you're dealing with complex issues, a professional has the expertise and equipment to accurately diagnose and repair the problem.

Conclusion

Choosing the correct battery group size and performing regular electrical system analyses are essential for maintaining your vehicle's reliability and performance. By understanding these concepts and taking preventative measures, you can avoid costly repairs and ensure that your vehicle's electrical system is functioning optimally. Remember to consult your owner's manual, use reliable battery size finder tools, and don't hesitate to seek professional help when needed. A well-maintained electrical system translates to a safer and more enjoyable driving experience. Regular maintenance and proactive diagnostics are key!