Catalytic Converter Nissan Titan 2005

The 2005 Nissan Titan, a full-size pickup truck, represents a significant period in automotive history, particularly concerning emissions control. A critical component in achieving acceptable emissions standards is the catalytic converter. This guide delves into the technical aspects of the catalytic converter found in the 2005 Nissan Titan, exploring its function, construction, diagnostic troubleshooting, and potential replacement considerations. This is tailored for curious readers and amateur engineers eager to grasp the inner workings of this essential pollution-reducing device.

Understanding the Basics of Catalytic Conversion

Before focusing specifically on the Titan's catalytic converter, it's crucial to understand the fundamental principles of catalytic conversion. Internal combustion engines produce several harmful pollutants, including hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx). The catalytic converter is designed to significantly reduce the levels of these pollutants before they are released into the atmosphere.

At its core, a catalytic converter relies on a chemical process called catalysis. A catalyst is a substance that accelerates a chemical reaction without being consumed in the reaction itself. In this case, precious metals such as platinum, palladium, and rhodium act as catalysts. These metals are applied in a thin layer to a ceramic substrate inside the converter.

The typical three-way catalytic converter performs three simultaneous tasks:

- Reduction of Nitrogen Oxides (NOx): NOx molecules are broken down into nitrogen (N2) and oxygen (O2).

- Oxidation of Carbon Monoxide (CO): CO is oxidized into carbon dioxide (CO2).

- Oxidation of Hydrocarbons (HC): HC are oxidized into carbon dioxide (CO2) and water (H2O).

The 2005 Nissan Titan Catalytic Converter: Specific Design and Configuration

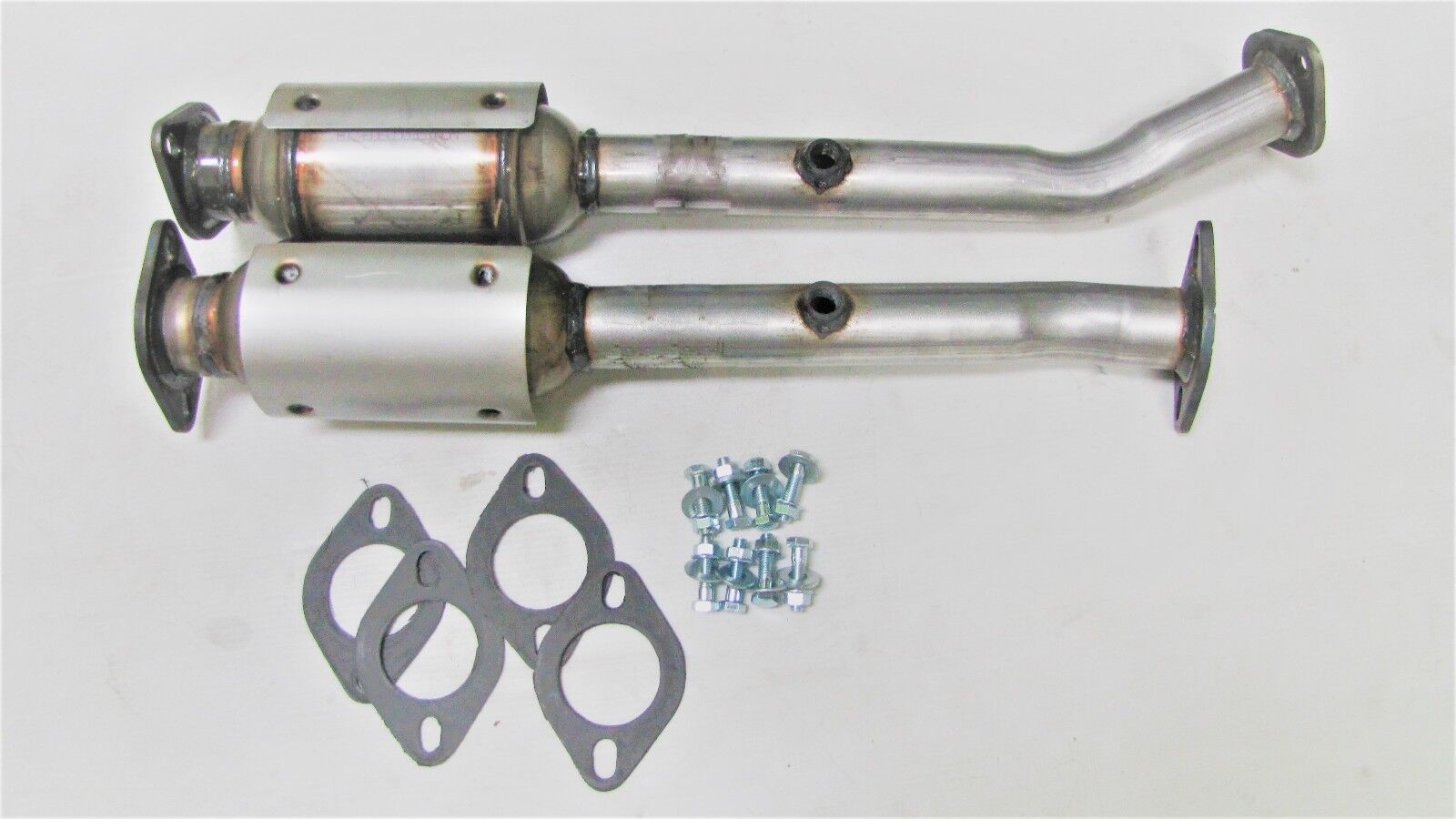

The 2005 Nissan Titan typically employs a dual catalytic converter system, meaning it has two converters, one for each bank of the V8 engine. This configuration is designed to handle the exhaust volume and flow rate generated by the large displacement engine effectively. The specific location of the converters is downstream of the exhaust manifolds but upstream of the muffler. This placement is crucial for optimal operating temperature.

The ceramic substrate within the converter is often described as a "honeycomb" structure. This design maximizes the surface area available for the catalytic reaction, allowing for efficient conversion within a relatively compact space. The substrate is coated with a washcoat, a porous layer containing the precious metal catalysts. This washcoat increases the surface area even further and provides a better distribution of the catalysts.

The converter is housed in a stainless steel casing, designed to withstand the high temperatures and corrosive environment of the exhaust system. The casing is typically welded shut to prevent leaks and maintain the integrity of the catalytic process.

The 2005 Titan's catalytic converter system also incorporates oxygen sensors. These sensors, located both upstream and downstream of the converter, monitor the oxygen content in the exhaust gas. The upstream sensor provides feedback to the engine control unit (ECU), allowing it to adjust the air-fuel mixture for optimal combustion. The downstream sensor monitors the efficiency of the catalytic converter. A significant difference in oxygen levels between the upstream and downstream sensors indicates that the converter is functioning correctly.

Diagnostic Trouble Codes (DTCs) and Common Failure Modes

Several Diagnostic Trouble Codes (DTCs) can indicate a problem with the catalytic converter. The most common DTC related to converter efficiency is P0420: Catalyst System Efficiency Below Threshold (Bank 1). A similar code, P0430, applies to Bank 2. This code suggests that the converter is not adequately reducing emissions.

Other DTCs, such as those related to oxygen sensor performance (e.g., P0130-P0167), can also indirectly point to a catalytic converter issue. A faulty oxygen sensor can provide incorrect feedback to the ECU, leading to an improper air-fuel mixture and potentially damaging the converter.

Common failure modes of catalytic converters in the 2005 Nissan Titan include:

- Clogging: Carbon buildup or physical damage to the substrate can restrict exhaust flow, reducing engine performance and potentially leading to overheating. Excessive oil consumption or coolant leaks into the combustion chamber can accelerate clogging.

- Poisoning: Exposure to certain substances, such as lead (found in some older fuels) or silicone (from certain gasket sealants), can deactivate the catalysts, rendering the converter ineffective.

- Melting: Overheating due to a rich air-fuel mixture or prolonged engine misfires can melt the ceramic substrate, causing it to collapse and restrict exhaust flow.

- Physical Damage: Impact from road debris can damage the converter casing or substrate.

It's crucial to diagnose the root cause of a catalytic converter failure before replacing the converter. Replacing a converter without addressing the underlying problem (e.g., engine misfires, oil leaks) will likely result in premature failure of the new converter.

Troubleshooting and Testing the Catalytic Converter

Several methods can be used to diagnose a potential catalytic converter issue:

- Visual Inspection: Check the converter casing for signs of physical damage, such as dents, cracks, or rust.

- Exhaust Backpressure Test: Use a backpressure gauge to measure the exhaust backpressure upstream of the converter. Excessive backpressure indicates a clogged converter. A normal reading for a V8 engine like in the 2005 Titan would be under 2 PSI at idle.

- Oxygen Sensor Analysis: Use a scan tool to monitor the voltage readings from the upstream and downstream oxygen sensors. The downstream sensor voltage should be relatively stable, while the upstream sensor voltage should fluctuate rapidly. A downstream sensor voltage that mirrors the upstream sensor voltage indicates a failing converter. However, note that this method isn't foolproof and may require further analysis.

- Infrared Thermometer: After the engine has reached operating temperature, use an infrared thermometer to measure the temperature of the converter inlet and outlet. The outlet temperature should be significantly higher than the inlet temperature if the converter is functioning correctly. Important safety note: exhaust components get very hot, take great care not to burn yourself during this step.

- Emissions Testing: A professional emissions test can provide definitive evidence of converter failure.

Before performing any diagnostic tests, ensure that the engine is properly tuned and that there are no other underlying engine problems that could be affecting converter performance.

Replacement Considerations

Replacing a catalytic converter can be a significant expense. When replacing the converter, it's essential to use a quality replacement part that meets or exceeds the original equipment manufacturer (OEM) specifications. Aftermarket converters are available at various price points, but it's crucial to choose a reputable brand to ensure proper performance and longevity. Cheaper units may not contain the necessary amount of precious metal catalysts to effectively reduce emissions.

In some regions, it is illegal to replace a catalytic converter with a non-compliant part. Check your local regulations before purchasing a replacement converter. In many cases, an aftermarket converter must be CARB (California Air Resources Board) compliant to be legal for use. These are typically more expensive but guarantee proper function and compliance.

When installing a new converter, ensure that all exhaust system connections are properly sealed to prevent leaks. Leaks can affect the performance of the converter and trigger DTCs.

Post-Installation Inspection: After replacing the catalytic converter, clear any DTCs and monitor the engine performance closely. Check for exhaust leaks and ensure that the oxygen sensor readings are within the normal range. Performing an emissions test after installation is a good practice to verify that the new converter is functioning correctly.

Prevention: To extend the life of your 2005 Nissan Titan's catalytic converter, address any engine issues promptly, use high-quality fuel, and avoid driving through areas with potential road hazards. Regular maintenance, including oil changes and tune-ups, can also help prevent premature converter failure.

The information provided here is for educational purposes and should not be considered a substitute for professional automotive advice. Consult a qualified mechanic for any repairs or diagnostic procedures.