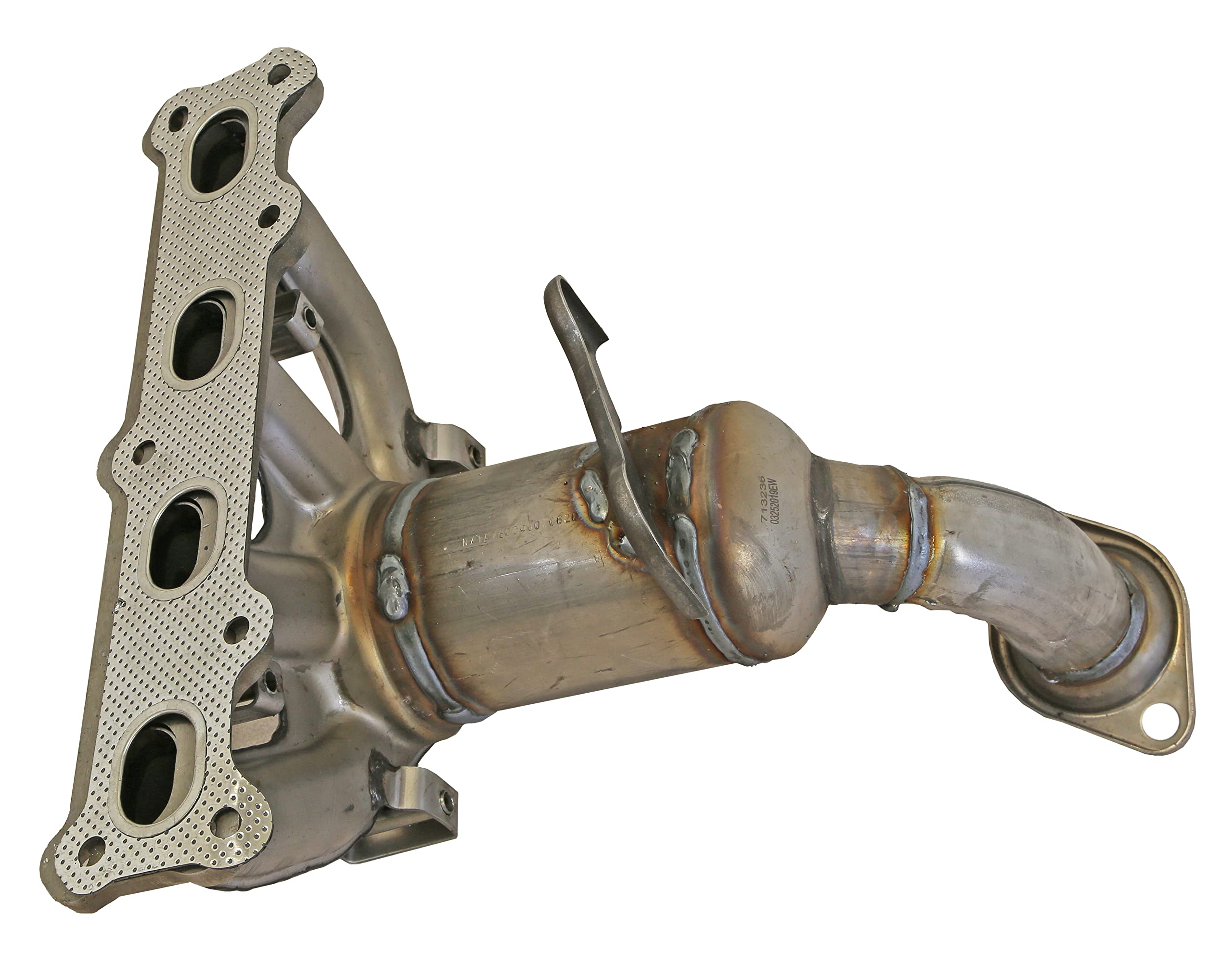

Catalytic Converter With Exhaust Manifold

The catalytic converter, often integrated with the exhaust manifold, is a crucial component in modern internal combustion engine vehicles. It plays a vital role in reducing harmful emissions before they are released into the atmosphere. This article delves into the intricacies of the catalytic converter and its integration with the exhaust manifold, exploring its design, function, and common issues.

The Exhaust Manifold: Gathering the Exhaust Gasses

Before we dive into the catalytic converter itself, it's essential to understand the function of the exhaust manifold. The exhaust manifold is the first component in the exhaust system. It's bolted directly to the cylinder head(s) of the engine and its primary task is to collect the high-temperature exhaust gases expelled from each cylinder after the combustion process. Its design is crucial for engine efficiency.

Traditionally, exhaust manifolds were simple cast iron structures, designed for durability and cost-effectiveness. However, modern vehicles often employ more sophisticated designs, including tubular headers, constructed from steel or even stainless steel. These headers are carefully engineered to optimize exhaust gas flow, reducing backpressure and potentially increasing engine power and fuel efficiency. By streamlining the exhaust path, these headers allow the engine to "breathe" more freely.

The exhaust manifold is subjected to extreme thermal stress, enduring rapid temperature fluctuations as hot exhaust gases flow through it intermittently. This constant heating and cooling can lead to cracking or warping over time, especially in older or less expensive cast iron manifolds.

The Catalytic Converter: A Chemical Transformation

The catalytic converter is situated downstream of the exhaust manifold, and in many modern designs, it's directly integrated into the manifold itself, forming a single unit. Its primary function is to convert harmful pollutants in the exhaust gas into less harmful substances through chemical reactions. These pollutants primarily consist of:

- Hydrocarbons (HC): Unburned fuel, contributing to smog.

- Carbon Monoxide (CO): A poisonous, odorless gas.

- Nitrogen Oxides (NOx): Contribute to smog and acid rain.

The catalytic converter achieves this chemical transformation using a combination of precious metals, typically platinum, palladium, and rhodium, which act as catalysts. A catalyst is a substance that speeds up a chemical reaction without being consumed in the process.

Two-Way vs. Three-Way Catalytic Converters

Early catalytic converters were "two-way" converters, designed to oxidize HC and CO into carbon dioxide (CO2) and water (H2O). However, they were ineffective at reducing NOx emissions. Modern vehicles predominantly use "three-way" catalytic converters, which simultaneously address all three pollutants:

- Reduction of NOx: Rhodium is used to reduce nitrogen oxides (NOx) into nitrogen (N2) and oxygen (O2).

- Oxidation of CO: Platinum is used to oxidize carbon monoxide (CO) into carbon dioxide (CO2).

- Oxidation of HC: Palladium is used to oxidize unburned hydrocarbons (HC) into carbon dioxide (CO2) and water (H2O).

Construction of a Catalytic Converter

A typical catalytic converter consists of a ceramic or metallic substrate with a honeycomb-like structure. This structure provides a large surface area for the catalyst to interact with the exhaust gases. The catalyst materials (platinum, palladium, and rhodium) are applied as a thin coating to the substrate. The substrate is then encased in a stainless steel shell to protect it from damage and provide structural integrity.

The honeycomb structure is designed to minimize backpressure while maximizing the contact area between the exhaust gases and the catalyst. This ensures efficient conversion of pollutants with minimal impact on engine performance.

Integration with the Exhaust Manifold

Integrating the catalytic converter directly into the exhaust manifold offers several advantages:

- Faster Warm-Up: Placing the converter closer to the engine results in faster warm-up. Catalytic converters are most effective when they reach operating temperature (typically around 400-800°C). A faster warm-up reduces emissions during the crucial cold-start phase, when the engine is running rich.

- Reduced Space Requirements: Combining the manifold and converter into a single unit can save space in the engine compartment, which is particularly important in modern vehicles with increasingly complex engine layouts.

- Improved Efficiency: By minimizing the distance between the engine and the converter, heat loss is reduced, helping the converter maintain its operating temperature and perform more efficiently.

However, integrated designs also present some challenges. The catalytic converter and manifold are now a single, more expensive unit. Replacing the manifold now requires replacing the converter, or vice versa, which increases maintenance costs. Furthermore, the increased heat load on the manifold can potentially shorten its lifespan. Because of this, careful material selection and design considerations are crucial for ensuring the durability of integrated exhaust manifold/catalytic converter assemblies.

Common Problems and Diagnostics

Catalytic converters are relatively durable components, but they can fail due to various factors:

- Contamination: The most common cause of catalytic converter failure is contamination. This can occur when excessive oil, coolant, or fuel enters the exhaust system. These contaminants can coat the catalyst, poisoning it and rendering it ineffective.

- Overheating: Prolonged overheating can damage the catalyst and even melt the substrate. This can be caused by a misfiring engine, a lean fuel mixture, or excessive backpressure.

- Physical Damage: The catalytic converter can be physically damaged by impacts from road debris.

- Age and Wear: Over time, the catalyst can become less effective due to normal wear and tear.

Symptoms of a failing catalytic converter can include:

- Reduced Engine Performance: The engine may feel sluggish or unresponsive.

- Poor Fuel Economy: The engine may consume more fuel than usual.

- Check Engine Light: The "Check Engine" light may illuminate, and a diagnostic trouble code (DTC) related to the catalytic converter may be stored. Codes such as P0420 ("Catalyst System Efficiency Below Threshold") are common indicators.

- Rattling Noise: A rattling noise from the exhaust system can indicate a broken or damaged substrate inside the converter.

- Failed Emissions Test: The vehicle may fail an emissions test due to excessive levels of HC, CO, or NOx.

Diagnosing catalytic converter problems typically involves using a diagnostic scan tool to read DTCs and monitoring the oxygen sensor readings upstream and downstream of the converter. Oxygen sensors measure the oxygen content in the exhaust gas. A healthy catalytic converter will significantly reduce the oxygen content downstream compared to upstream. If the oxygen sensor readings are similar, it suggests that the converter is not functioning properly.

Maintenance and Prevention

While catalytic converters are designed to last for many years, proper maintenance can help extend their lifespan:

- Regular Engine Maintenance: Keeping the engine properly tuned and maintained is crucial. This includes regular oil changes, spark plug replacements, and addressing any engine misfires promptly.

- Avoid Short Trips: Short trips can prevent the catalytic converter from reaching its operating temperature, leading to incomplete combustion and increased emissions.

- Use Quality Fuel: Using high-quality fuel can help prevent fuel system problems that can damage the catalytic converter.

- Address Oil Leaks: Repair any oil leaks promptly to prevent oil from entering the exhaust system.

Conclusion

The catalytic converter, especially when integrated with the exhaust manifold, is a vital component for reducing harmful emissions from vehicles. Understanding its design, function, and potential problems is essential for maintaining vehicle performance and protecting the environment. By following proper maintenance practices and addressing any issues promptly, you can help ensure the longevity and effectiveness of your vehicle's catalytic converter.