Caterpillar Warning Symbols And Meanings

Caterpillar, or CAT, is a name synonymous with heavy machinery. From bulldozers sculpting landscapes to massive mining trucks hauling tons of ore, CAT equipment powers industries worldwide. Integral to the safe and efficient operation of these machines is a comprehensive warning system, communicated through a series of standardized symbols. Understanding these symbols is crucial, not only for operators but also for mechanics, technicians, and anyone involved in the vicinity of this powerful equipment. This guide delves into the intricacies of Caterpillar warning symbols, exploring their meanings, categories, and the underlying principles that govern their design.

Categories of Warning Symbols

CAT warning symbols are generally categorized based on the severity and nature of the potential hazard. These categories help operators quickly assess the risk and take appropriate action. The most common categories include:

Hazard Alert

The hazard alert symbol, typically an equilateral triangle with an exclamation mark inside, is the most ubiquitous and important symbol on CAT equipment. It signals a potentially dangerous situation that could result in serious injury or death. The specific hazard is usually described by an accompanying pictogram or text.

Safety Alert

Safety alert symbols denote potential hazards that are less immediate than those signaled by the hazard alert. These could indicate improper operating procedures, the need for safety gear, or awareness of specific machine limitations. While not always immediately life-threatening, ignoring safety alerts can lead to equipment damage, minor injuries, or reduced operational efficiency.

Maintenance Alert

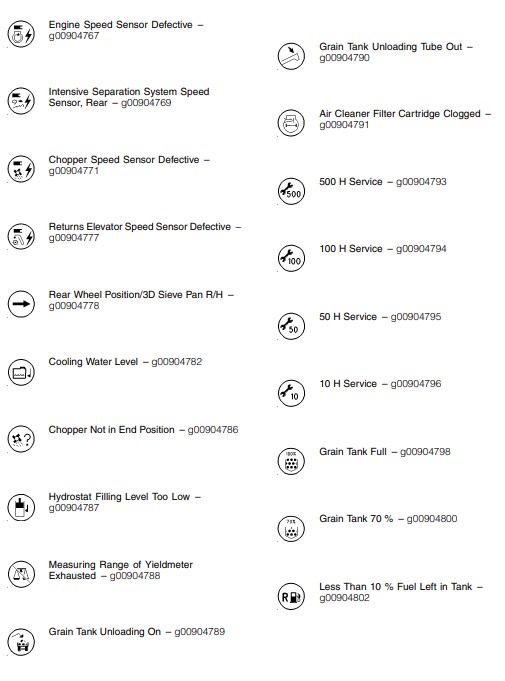

These symbols indicate the need for immediate maintenance or inspection. They often relate to fluid levels (oil, coolant, hydraulic fluid), filter condition, or component wear. Addressing maintenance alerts promptly prevents costly breakdowns and ensures the longevity of the machine.

Operational Alert

Operational alerts inform the operator about the machine's performance or limitations. These could include warnings about exceeding speed limits, operating on steep slopes, or approaching maximum load capacity. Adhering to operational alerts ensures safe and efficient operation within the machine's design parameters.

Deciphering Common Caterpillar Warning Symbols

While CAT employs a vast library of warning symbols, certain pictograms appear more frequently than others. Here's a breakdown of some of the most common symbols and their meanings:

- Engine Oil Pressure Low: A stylized oil can with a dripping spout and a descending droplet, often accompanied by an exclamation mark. This indicates critically low engine oil pressure, potentially leading to severe engine damage. Immediate shutdown and inspection are required.

- Coolant Temperature High: A thermometer immersed in liquid, often with the liquid rising towards the top of the thermometer. This signals an overheated engine. Reduced load or shutdown may be necessary to prevent further damage.

- Hydraulic Oil Temperature High: Similar to the coolant temperature symbol, but often distinguished by a different color or the presence of hydraulic lines. Indicates excessive hydraulic oil temperature, which can damage hydraulic components.

- Air Filter Restriction: A stylized air filter with an arrow pointing into it and a solid line blocking the arrow. This means the air filter is clogged and needs cleaning or replacement. A restricted air filter reduces engine performance and increases fuel consumption.

- Battery Charging System Fault: A battery symbol with a plus and minus sign, often with an exclamation mark. Indicates a problem with the battery charging system, such as a faulty alternator or voltage regulator.

- Brake System Malfunction: A brake shoe symbol, often with an exclamation mark or a warning triangle. This signifies a problem with the braking system, requiring immediate attention.

- Seat Belt Required: A person wearing a seat belt. This is a reminder to fasten the seat belt before operating the machine.

- Hearing Protection Required: Earmuffs. Indicates the need to wear hearing protection due to high noise levels.

- Safety Glasses Required: Safety glasses. Indicates the need to wear safety glasses to protect the eyes from flying debris or other hazards.

- High Voltage: A jagged lightning bolt inside a triangle. Indicates the presence of high-voltage electrical components. Extreme caution is necessary.

- Rotating Fan: A stylized fan with rotating blades. Indicates the presence of a rotating fan that can cause serious injury. Keep hands and loose clothing away.

- Hot Surface: A hand touching a surface with radiating heat waves. Indicates a hot surface that can cause burns. Avoid contact.

- Crushing Hazard: Two approaching surfaces crushing an object between them. Indicates a risk of being crushed between moving parts or equipment.

- Falling Object: An object falling from above. Indicates a risk of being struck by falling objects. Wear appropriate head protection.

The Importance of Standardized Symbols

The use of standardized warning symbols is crucial for several reasons. Firstly, it transcends language barriers. A pictogram is universally understood, regardless of the operator's native language. This is particularly important in international operations where operators may come from diverse backgrounds.

Secondly, standardized symbols ensure consistency across different models and generations of CAT equipment. An operator familiar with one CAT machine can readily understand the warning system on another, reducing the learning curve and minimizing the risk of misinterpretation. This consistency also benefits mechanics and technicians who service a wide range of CAT equipment.

Thirdly, the use of internationally recognized symbols enhances safety and promotes a culture of awareness. Operators become accustomed to seeing and understanding these symbols, leading to quicker recognition and response to potential hazards. This contributes to a safer working environment and reduces the likelihood of accidents.

Evolution of Warning Symbols

Caterpillar's warning symbol system is not static; it evolves over time to reflect advances in technology, changes in safety regulations, and feedback from operators and technicians. Newer machines often incorporate more sophisticated electronic displays that provide more detailed information about potential hazards. These displays may include text descriptions in multiple languages, diagnostic codes, and even interactive troubleshooting guides.

Furthermore, CAT continuously refines its warning symbols based on ergonomic studies and human factors research. The goal is to create symbols that are easily recognizable, unambiguous, and memorable. This iterative process ensures that the warning system remains effective and relevant in the face of evolving workplace demands.

Accessing Symbol Information

The most reliable source of information on Caterpillar warning symbols is the Operator's Manual for the specific machine in question. This manual provides a comprehensive overview of all the symbols used on the machine, along with detailed explanations of their meanings and recommended actions. In addition, Caterpillar offers online resources and training materials that cover warning symbol identification and interpretation.

It's crucial to consult the official documentation rather than relying on anecdotal information or outdated sources. Caterpillar continuously updates its documentation to reflect the latest changes in its warning system. Using the correct information ensures that operators and technicians are properly informed and can respond appropriately to potential hazards.

Beyond the Symbols: A Culture of Safety

While understanding Caterpillar warning symbols is essential, it's only one component of a comprehensive safety program. Creating a culture of safety requires a holistic approach that encompasses training, procedures, and a commitment to continuous improvement. Operators must be properly trained on the safe operation of the machine, including the interpretation of warning symbols and the appropriate response to potential hazards. Regular inspections and maintenance are also crucial to ensure that the machine is in safe working condition. Furthermore, a strong safety culture encourages open communication and reporting of potential hazards, allowing for proactive intervention and prevention of accidents.

In conclusion, Caterpillar warning symbols serve as a vital communication tool, conveying critical information about potential hazards and machine status. Understanding these symbols is not just a matter of memorization; it's about developing a keen awareness of the machine and its environment. By diligently heeding these warnings and embracing a culture of safety, operators, technicians, and everyone involved can contribute to a safer and more productive work environment.