Chevy 350 Swap Kit Adapter And Mounting Solutions

The Chevrolet 350 small-block V8. Few engines are as deeply woven into the fabric of automotive culture. From its ubiquitous presence in trucks and muscle cars to its remarkable adaptability for swaps into virtually anything with wheels, the Chevy 350 remains a cornerstone of hot-rodding. But shoehorning this iconic powerplant into a vehicle that wasn't originally designed for it requires careful planning and, crucially, the right adapter and mounting solutions. This guide will delve into the technical aspects of these crucial components, offering insights for anyone considering a Chevy 350 swap.

Understanding the Challenges

Before diving into specific adapter and mounting kits, it's essential to understand the core challenges involved in a swap. A Chevy 350, while relatively compact for a V8, still presents significant space and engineering hurdles:

- Engine Bay Compatibility: The physical dimensions of the 350 must be accommodated within the target vehicle's engine bay. This includes height, width, and length clearances, as well as accounting for accessory drives (alternator, power steering pump, A/C compressor).

- Mounting Points: The factory engine mounts on the target vehicle almost certainly won't align with the 350's block. Custom mounts or adapters are therefore indispensable.

- Drivetrain Alignment: The 350's crankshaft centerline needs to be precisely aligned with the transmission input shaft. Misalignment can lead to premature wear on the transmission, driveshaft, and even the engine itself.

- Exhaust System: Adapting or fabricating an exhaust system that fits the engine bay and connects to the existing (or modified) exhaust system is crucial.

- Cooling System: Ensuring adequate cooling for the 350 is paramount. This might involve upgrading the radiator, modifying coolant hose routing, and/or adding an electric fan.

- Fuel System: The fuel system needs to deliver the correct pressure and volume of fuel to the 350. This often means upgrading the fuel pump, fuel lines, and potentially the fuel tank.

- Electrical System: Integrating the 350's wiring harness with the target vehicle's electrical system is a critical step. This includes wiring for the ignition system, fuel injection (if applicable), sensors, and gauges.

Ignoring any of these challenges can lead to a poorly executed swap that is unreliable, unsafe, or both.

Adapter Plates: Bridging the Gap

Adapter plates serve as an interface between the Chevy 350 engine block and the existing engine mounts on the target vehicle's chassis. They are typically made from high-strength steel or aluminum. The critical factors to consider when choosing adapter plates are:

- Accuracy of Fitment: The adapter plates must be precisely manufactured to ensure proper engine alignment. Look for plates that are CNC machined for optimal accuracy.

- Material Strength: The plates must be strong enough to withstand the forces generated by the engine. Steel is generally preferred for high-horsepower applications, while aluminum can be suitable for milder builds.

- Offset Considerations: Some adapter plates may incorporate an offset to reposition the engine slightly within the engine bay. This can be necessary to clear obstacles or improve drivetrain alignment.

- Hardware Quality: Always use high-quality hardware (bolts, nuts, washers) to secure the adapter plates to the engine block and chassis. Grade 8 hardware is generally recommended.

When installing adapter plates, meticulous attention to detail is essential. Torque specifications must be strictly adhered to to prevent loosening or failure. Use thread locker (such as Loctite) on all fasteners.

Engine Mounts: Absorbing Vibration and Securing the Engine

Engine mounts play a crucial role in isolating engine vibrations from the chassis and providing a secure anchor for the engine. There are several types of engine mounts available:

- Rubber Mounts: Rubber mounts are the most common type of engine mount. They provide excellent vibration damping but are less durable than other types.

- Polyurethane Mounts: Polyurethane mounts offer a balance between vibration damping and durability. They are stiffer than rubber mounts, which can result in slightly more vibration being transmitted to the chassis but also provide better engine control.

- Solid Mounts: Solid mounts provide the most direct connection between the engine and the chassis. They offer the best engine control but transmit the most vibration. Solid mounts are generally only used in racing applications.

- Hydraulic Mounts: Hydraulic mounts use fluid-filled chambers to dampen vibrations. They offer excellent vibration damping and are often used in luxury vehicles.

Choosing the right type of engine mount depends on the intended use of the vehicle. For a daily driver, rubber or polyurethane mounts are typically the best choice. For a racing application, solid mounts may be preferred. When using adapter plates, ensure that the engine mounts are compatible with the plates. Some adapter plates may require specific engine mounts.

Proper installation of engine mounts is critical for safety and performance. Ensure that the mounts are securely attached to the engine block and chassis. Torque specifications must be followed carefully.

Crossmembers and Frame Modifications

In some cases, simply using adapter plates and engine mounts may not be sufficient to properly install the Chevy 350. The existing crossmember or frame may need to be modified or replaced. This is often necessary when the engine is significantly larger or has different mounting points than the original engine.

Crossmember modifications can involve:

- Relocating or reinforcing existing crossmember mounting points.

- Fabricating a new crossmember.

- Using a universal crossmember designed for engine swaps.

Frame modifications can be more complex and may require welding. These modifications can involve:

- Reinforcing the frame to handle the increased power of the 350.

- Modifying the frame to clear the engine and its accessories.

- Fabricating new frame mounting points for the engine.

Frame modifications should only be performed by experienced welders and fabricators. Improperly executed frame modifications can compromise the structural integrity of the vehicle.

Drivetrain Considerations

Beyond the engine mounts themselves, consider how the Chevy 350's power will be transmitted to the wheels. This involves the transmission, driveshaft, and rear axle.

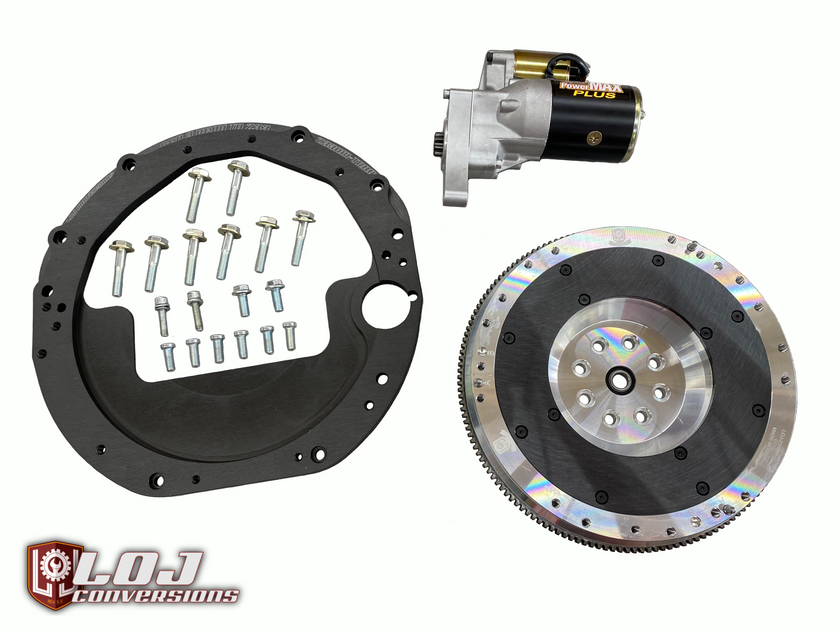

- Transmission Compatibility: The Chevy 350 has been paired with numerous transmissions throughout its history. Popular choices for swaps include the Turbo 350, Turbo 400, and 700R4 automatic transmissions, as well as various manual transmissions. Ensure that the chosen transmission is compatible with the 350's bellhousing pattern and can handle the engine's power output. Adapter plates may be required to mate a non-Chevy transmission to the 350.

- Driveshaft Length and Balance: After installing the engine and transmission, the driveshaft length will likely need to be adjusted. A qualified driveshaft shop can shorten or lengthen the driveshaft and ensure that it is properly balanced.

- Rear Axle Strength: The rear axle must be strong enough to handle the increased power of the 350. A weak rear axle can fail prematurely, especially under hard acceleration. Consider upgrading the rear axle to a stronger unit if necessary.

Careful planning and execution are essential for a successful drivetrain swap. Proper alignment and component selection are critical for reliability and performance.

Beyond the Basics: Accessory Drive Adapters

The Chevy 350 used various accessory drive configurations over the years. Depending on the target vehicle and the chosen accessories (power steering, A/C, etc.), adapter brackets may be needed to mount these accessories to the engine. These adapters ensure proper belt alignment and tension.

Conclusion

Successfully swapping a Chevy 350 into a different vehicle is a complex undertaking that requires careful planning, meticulous attention to detail, and a solid understanding of automotive engineering principles. Choosing the correct adapter plates, engine mounts, and addressing drivetrain compatibility are essential steps in ensuring a reliable and enjoyable swap. By carefully considering the challenges and selecting the appropriate components, you can successfully transplant this iconic engine into your project car.

Remember, safety is paramount. If you lack the necessary skills or experience, consult with a qualified mechanic or fabricator to ensure that the swap is performed correctly and safely. A well-executed Chevy 350 swap can transform a vehicle, providing a significant boost in power and performance. But a poorly executed swap can lead to frustration, expense, and even danger. Do your research, plan carefully, and take your time to ensure a successful outcome.