Control Arm Bushing Material Properties And Durability

Let's dive into the often-overlooked but critically important component of your car's suspension: the control arm bushing. These humble bits of rubber (or increasingly, polyurethane) play a vital role in vehicle handling, ride comfort, and overall durability. Understanding their material properties and how those properties impact longevity is key for any enthusiast looking to improve their car's performance or simply keep it running smoothly.

What Are Control Arm Bushings and Why Do They Matter?

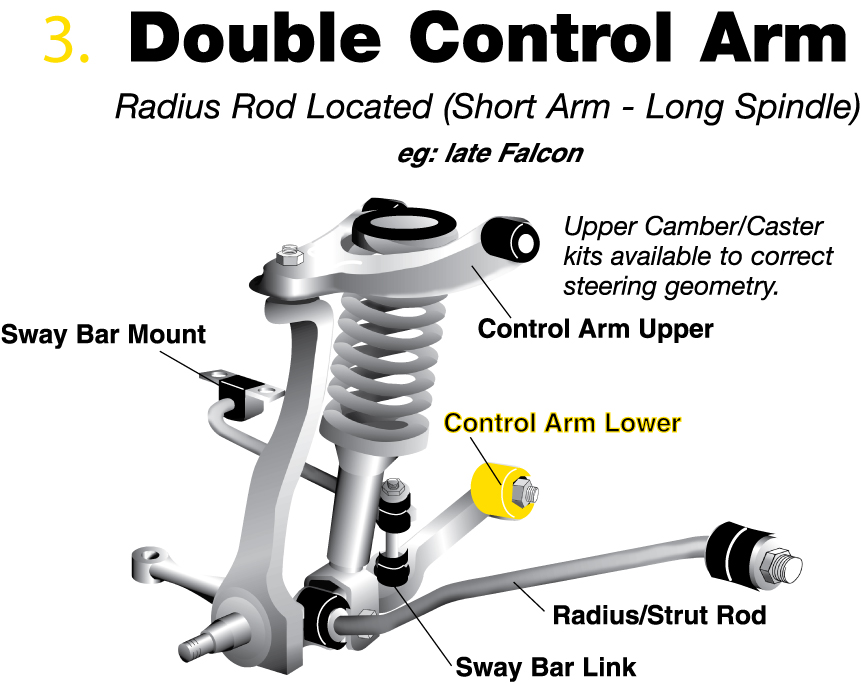

Control arms are the suspension links that connect your vehicle's chassis to the wheel hub. They allow the wheels to move up and down while maintaining proper alignment. Bushings are elastomeric (meaning they can deform under stress and return to their original shape) components that act as the pivot points between the control arm and the chassis or wheel hub. Their primary functions are:

- Isolating Noise and Vibration: They absorb impacts and dampen vibrations from the road, preventing them from transmitting directly to the vehicle's cabin.

- Allowing Suspension Movement: They accommodate the articulation of the suspension as the wheels move up and down and the chassis rolls.

- Maintaining Wheel Alignment: By controlling the movement of the control arm, they help keep the wheels pointed in the right direction for optimal handling and tire wear.

A worn or damaged control arm bushing can lead to a number of problems, including sloppy handling, excessive tire wear, clunking noises from the suspension, and even reduced braking performance. Replacing them can dramatically improve your car's ride and handling, often making it feel like new again.

Common Control Arm Bushing Materials: Properties and Trade-offs

The two most common materials used for control arm bushings are rubber and polyurethane. Each has its own set of advantages and disadvantages:

Rubber Bushings

Rubber has been the traditional choice for bushings for decades. It offers excellent vibration damping and a comfortable ride. However, rubber is susceptible to degradation from exposure to oil, grease, and UV light. There are generally two types of rubber used in bushings: Natural Rubber and Synthetic Rubber (like Neoprene or EPDM).

- Natural Rubber: Offers the best damping properties, providing a quiet and comfortable ride. However, it has lower resistance to oil, grease, and ozone compared to synthetic alternatives.

- Synthetic Rubber: Provides better resistance to environmental factors and chemicals but generally exhibits slightly reduced damping compared to natural rubber.

Key material properties to consider for rubber bushings include:

- Durometer (Shore A): This measures the hardness of the rubber. Lower durometer values indicate softer, more compliant rubber, which provides better vibration damping but may wear faster. Higher durometer values indicate harder rubber, which offers better control and durability but transmits more vibration. Typically, OEM rubber bushings range from 50-70 Shore A.

- Tensile Strength: This measures the amount of force required to break the rubber. Higher tensile strength indicates a more durable material that can withstand higher stresses.

- Elongation at Break: This measures how much the rubber can stretch before it breaks. Higher elongation at break indicates a more flexible material that can better absorb impacts.

- Compression Set: This measures the permanent deformation of the rubber after being subjected to a compressive load. Lower compression set indicates better resistance to permanent deformation and longer bushing life.

The primary failure mode for rubber bushings is cracking and tearing due to age, heat, and exposure to contaminants. They can also become deformed over time, leading to increased suspension play and reduced handling precision.

Polyurethane Bushings

Polyurethane (PU) bushings are a popular upgrade for performance-oriented vehicles. They are significantly stiffer and more durable than rubber, offering improved handling and responsiveness. However, they also transmit more vibration and noise into the cabin. PU bushings are generally resistant to oil, grease, and other chemicals, making them a longer-lasting option in harsh environments.

Key material properties to consider for polyurethane bushings include:

- Durometer (Shore A): PU bushings are typically available in a wider range of durometers than rubber bushings. Common values range from 70 Shore A (relatively soft) to 95 Shore A (very hard). Higher durometer values provide greater control and reduced suspension flex but at the expense of ride comfort.

- Tensile Strength: PU generally exhibits higher tensile strength than rubber, making it more resistant to tearing and deformation.

- Elongation at Break: While PU is strong, its elongation at break is typically lower than rubber. This means it's less able to stretch and absorb large impacts, potentially leading to cracking or shattering under extreme stress.

- Tear Resistance: This measures the resistance of the material to tearing. Polyurethane typically has excellent tear resistance.

- Hydrolysis Resistance: This measures the resistance of the material to degradation from exposure to water. Some types of polyurethane are more susceptible to hydrolysis than others.

A potential issue with polyurethane bushings is squeaking. Because they're stiffer, they can generate noise as they articulate within the control arm. Applying a suitable grease during installation (and periodically thereafter) is crucial to prevent this. Be sure to use a grease specifically formulated for polyurethane, as some petroleum-based greases can degrade the material.

Durability Considerations: Factors Affecting Bushing Life

The lifespan of a control arm bushing depends on a variety of factors, including:

- Material Quality: Higher-quality materials will generally last longer. Look for bushings made from reputable manufacturers known for their quality control.

- Driving Conditions: Frequent driving on rough roads or aggressive driving will accelerate bushing wear.

- Environmental Factors: Exposure to extreme temperatures, UV light, and corrosive chemicals can degrade the bushing material.

- Vehicle Weight: Heavier vehicles place more stress on the suspension components, leading to faster bushing wear.

- Proper Installation: Incorrect installation can damage the bushing and shorten its lifespan. Always follow the manufacturer's instructions carefully.

- Lubrication (For Polyurethane): As mentioned, proper lubrication of polyurethane bushings is essential to prevent squeaking and premature wear.

Extending Bushing Life

Here are some tips to help extend the life of your control arm bushings:

- Regular Inspection: Inspect your bushings regularly for signs of wear, such as cracks, tears, or excessive play. Catching problems early can prevent more serious damage.

- Proper Lubrication (For Polyurethane): Apply a suitable grease to polyurethane bushings periodically to prevent squeaking and wear.

- Avoid Harsh Chemicals: Avoid exposing your bushings to harsh chemicals, such as degreasers or solvents.

- Drive Sensibly: Avoid driving aggressively on rough roads.

- Consider Upgrading: If you frequently drive on rough roads or demand high performance from your suspension, consider upgrading to polyurethane bushings for increased durability. However, be prepared for a potentially harsher ride.

Choosing the Right Bushing Material

The best bushing material for your car depends on your driving style and priorities. Here's a quick guide:

- Daily Driver: Rubber bushings are typically the best choice for daily drivers, as they provide a comfortable ride and adequate durability for normal driving conditions.

- Performance Enthusiast: Polyurethane bushings are a good option for performance enthusiasts who prioritize handling and responsiveness over ride comfort.

- Track Car: Very stiff polyurethane or even solid bushings (like spherical bearings) are often used in track cars to minimize suspension flex and maximize handling precision. However, these options offer very little vibration damping and are not suitable for street use.

When selecting polyurethane bushings, pay close attention to the durometer rating. A higher durometer rating will provide greater control but will also transmit more vibration and noise. It's often best to start with a relatively soft polyurethane bushing (around 70-80 Shore A) and then move to a harder bushing if needed.

Conclusion

Control arm bushings are a critical part of your vehicle's suspension system. Understanding their material properties and durability considerations is essential for maintaining your car's ride and handling. By choosing the right bushing material and taking proper care of your suspension, you can ensure a smooth, comfortable, and safe driving experience for years to come. Don't underestimate the impact of these seemingly small components; they play a huge role in how your car feels and performs.