Dual Tip Exhaust System Backpressure And Flow Characteristics

The exhaust system is a crucial component of any internal combustion engine, responsible for efficiently removing spent gases from the cylinders. While a single exhaust outlet used to be the norm, dual-tip exhaust systems have become increasingly prevalent, adorning everything from sporty sedans to high-performance SUVs. Beyond aesthetics, dual-tip designs raise pertinent questions about their impact on exhaust backpressure and flow characteristics. Do they offer genuine performance benefits, or are they primarily a styling statement? This guide delves into the technical aspects of dual-tip exhaust systems, exploring their intricacies and dissecting their effects on engine performance.

Understanding Exhaust Backpressure

Before diving into the specifics of dual-tip exhausts, it's essential to grasp the concept of exhaust backpressure. Backpressure, in its simplest form, is the resistance to exhaust gas flow within the exhaust system. It's measured in units like PSI or kPa, and its magnitude is influenced by several factors, including pipe diameter, bends, catalytic converter design, and muffler construction. Too much backpressure can hinder the engine's ability to efficiently expel exhaust gases, leading to reduced volumetric efficiency, lower horsepower, and decreased fuel economy. Imagine trying to exhale forcefully through a tiny straw – the resistance you feel is analogous to exhaust backpressure.

Conversely, too little backpressure, particularly in naturally aspirated engines, can also be detrimental. This is because exhaust pulses can create a scavenging effect, drawing out the remaining exhaust gases from the cylinder and even aiding in the intake of fresh air-fuel mixture. A completely free-flowing exhaust system might disrupt this scavenging effect, especially at lower engine speeds, resulting in a loss of low-end torque. The key is to strike a balance – to optimize exhaust flow without sacrificing the beneficial effects of controlled backpressure.

The Dual-Tip Design: A Closer Look

Dual-tip exhaust systems can be categorized into two primary configurations:

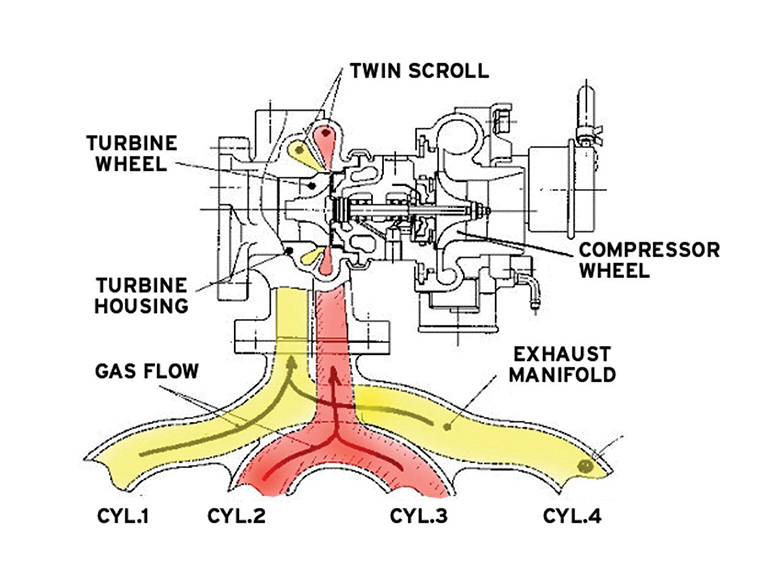

True Dual Exhaust Systems

A true dual exhaust system features two separate exhaust pipes running independently from the engine's exhaust manifolds or headers all the way to the tailpipes. Each bank of cylinders has its dedicated exhaust pathway. This design is typically found on V-engines (V6, V8, etc.) where each cylinder bank can be treated as a separate engine, benefiting from independent exhaust tuning. A true dual system can potentially offer improved exhaust flow and reduced backpressure compared to a single exhaust system, as each cylinder bank isn't forced to share a common exhaust pathway. This separation can minimize exhaust pulse interference and optimize scavenging effects.

Dual Outlet Systems (Split Exhausts)

A dual outlet system, often mislabeled as a "true dual," typically involves a single exhaust pipe emanating from the engine, which then splits into two outlets near the rear of the vehicle. This configuration is more common on inline engines and transversely mounted engines in front-wheel-drive vehicles. The purpose of the split is primarily aesthetic, mimicking the appearance of a true dual system. In most cases, a dual outlet system offers minimal performance gains compared to a well-designed single exhaust system. The split section can even introduce additional turbulence and backpressure if not carefully engineered.

Backpressure and Flow Characteristics of Dual-Tip Systems

The impact of a dual-tip exhaust system on backpressure and flow characteristics hinges heavily on its design. Let's consider each type:

True Dual Exhaust Systems

A properly designed true dual exhaust system offers the potential for reduced backpressure and improved exhaust flow compared to a single exhaust system. The independent exhaust pathways for each cylinder bank minimize exhaust pulse interference, allowing for a more efficient evacuation of exhaust gases. The larger overall cross-sectional area also contributes to lower backpressure. However, several factors can negate these potential benefits:

- Pipe Diameter: If the diameter of the individual pipes in a true dual system is too small, it can still create significant backpressure, negating the benefits of the dual design.

- Bends and Routing: Sharp bends in the exhaust pipes can significantly increase backpressure. A well-designed system will minimize the number and severity of bends.

- Muffler Design: The mufflers used in a true dual system must be designed to minimize restriction. Chambered mufflers, while offering good sound attenuation, can often introduce significant backpressure. Straight-through mufflers are generally preferred for performance applications.

- X-Pipes and H-Pipes: Connecting the two exhaust pipes with an X-pipe or H-pipe can further enhance exhaust flow and scavenging. These crossover pipes allow exhaust pulses from one cylinder bank to help evacuate gases from the other, improving cylinder filling and overall engine performance.

Therefore, simply adding a true dual exhaust system doesn't guarantee performance gains. The system must be carefully engineered to optimize flow and minimize backpressure.

Dual Outlet Systems (Split Exhausts)

As previously mentioned, a dual outlet system typically offers minimal performance benefits. The primary restriction in the exhaust system remains the single pipe leading from the engine. The split near the rear of the vehicle simply divides the exhaust flow into two outlets. While the dual outlets might slightly reduce backpressure compared to a single outlet with the same overall cross-sectional area, the difference is usually negligible. In some cases, poorly designed split sections can actually increase backpressure due to turbulence and flow disruption.

However, a dual outlet system can offer a slightly improved exhaust note, as the two outlets can produce a fuller and more aggressive sound. Furthermore, the aesthetic appeal of dual exhaust tips can be a significant factor for many car enthusiasts.

Factors Influencing Backpressure and Flow

Several factors contribute to the overall backpressure and flow characteristics of any exhaust system, including:

- Pipe Diameter: A larger pipe diameter generally reduces backpressure, but excessively large pipes can reduce exhaust velocity and scavenging effects.

- Material: Stainless steel exhaust systems are more durable and resistant to corrosion than mild steel systems.

- Catalytic Converter: High-flow catalytic converters minimize restriction compared to stock converters.

- Muffler Design: As mentioned earlier, straight-through mufflers are generally preferred for performance.

- Welding Technique: Smooth, clean welds minimize turbulence and improve flow.

Conclusion

Dual-tip exhaust systems, particularly true dual systems, can offer performance benefits by reducing backpressure and improving exhaust flow. However, the extent of these benefits depends heavily on the design of the system and the overall exhaust system configuration. A poorly designed dual system can actually hinder performance. Dual outlet systems (split exhausts) are primarily aesthetic enhancements, offering minimal performance gains. Ultimately, the best exhaust system for a particular application depends on the engine type, intended use, and desired performance characteristics. Careful consideration of these factors is crucial for selecting an exhaust system that delivers both performance and aesthetic appeal.

Before making any modifications to your exhaust system, it's always advisable to consult with a qualified automotive technician or performance specialist to ensure that the chosen system is appropriate for your vehicle and driving needs.

Disclaimer: This article provides general information about dual-tip exhaust systems. Specific performance gains or losses may vary depending on the vehicle, engine, and exhaust system configuration.