Engine Swap Cost Analysis And Parts List Compilation

Engine swaps. The very phrase conjures images of screaming engines, tire smoke, and the satisfying realization of a significant performance upgrade. But beneath the surface of this automotive alchemy lies a complex web of planning, execution, and, crucially, cost analysis. An engine swap isn't just bolting in a bigger motor; it's a holistic engineering project with potentially significant financial implications. This guide will walk you through the intricate process of compiling a comprehensive parts list and accurately estimating the cost of your dream engine swap.

Understanding the Scope: Defining the Swap

Before even considering parts, the most crucial step is defining the scope of the swap. This includes not just the engine itself, but the entire drivetrain and supporting systems. Consider these key questions:

- Engine Choice: What engine are you using? Is it from the same manufacturer, or are you venturing into a more complex, cross-brand swap? A straightforward swap (e.g., replacing an older small-block Chevy with a newer LS variant in a classic Camaro) will generally be less expensive than swapping a completely different engine family (e.g., a Toyota 2JZ into a Mazda Miata).

- Drivetrain Compatibility: Will the existing transmission bolt up to the new engine? If not, you'll need a new transmission, potentially a custom adapter plate, and possibly a new driveshaft. Consider the transmission's torque capacity – is it rated to handle the new engine's power output?

- Mounting and Fitment: Will the new engine physically fit into the engine bay? Are custom engine mounts required? Will the hood close? Clearance issues can lead to unexpected fabrication costs.

- Electrical System: Is the wiring harness compatible? Will you need a standalone engine management system (EMS), also known as an ECU, or can the existing ECU be reprogrammed? Modern engines often rely on complex CAN bus networks, requiring significant electrical expertise to integrate.

- Fuel System: Can the existing fuel pump and injectors supply enough fuel for the new engine? You might need a higher-capacity fuel pump, larger injectors, and potentially new fuel lines.

- Cooling System: Is the existing radiator sufficient? Will you need a larger radiator, new hoses, and potentially a custom cooling fan setup?

- Exhaust System: Will the existing exhaust manifolds or headers bolt up to the new engine? You'll likely need a custom exhaust system, including headers, catalytic converters (if required), and mufflers.

- Emissions Compliance: Does the swap need to comply with emissions regulations? This can add significant cost and complexity, especially in states with strict emissions testing.

Answering these questions will give you a solid foundation for creating your parts list. The more thoroughly you define the scope, the more accurate your cost estimate will be.

Compiling the Parts List: A Detailed Breakdown

The parts list is the heart of the cost analysis. It's a meticulous inventory of every component required for the swap. Here's a breakdown of the key categories and considerations:

1. The Engine Itself:

This is the most obvious cost, but even here, there are nuances:

- New vs. Used: A new crate engine offers the peace of mind of a warranty and known history, but it's significantly more expensive. A used engine can be a budget-friendly option, but it carries the risk of hidden problems. A thorough inspection, including a compression test and leak-down test, is crucial.

- Complete vs. Long Block vs. Short Block: A complete engine includes all accessories (alternator, starter, power steering pump, etc.), while a long block includes the cylinder head(s) but not the accessories. A short block consists only of the engine block, crankshaft, pistons, and connecting rods. Choose the option that best suits your needs and budget.

- Core Charge: Some suppliers require a core charge, which is a deposit refunded upon returning your old engine.

- Shipping Costs: Engines are heavy and expensive to ship. Factor this into your budget.

2. Transmission and Drivetrain:

As mentioned earlier, the transmission is a critical component. Consider these factors:

- New vs. Used: Similar to engines, transmissions come in new and used options. A rebuilt or remanufactured transmission can be a good compromise between cost and reliability.

- Adapter Plates: If the engine and transmission aren't directly compatible, you'll need a custom adapter plate. These can be expensive, especially for rare combinations.

- Driveshaft: The driveshaft might need to be shortened or lengthened to match the new drivetrain configuration.

- Clutch/Torque Converter: Ensure the clutch or torque converter is rated to handle the new engine's power output.

- Differential: The differential's gear ratio might need to be changed to optimize performance with the new engine and transmission.

3. Engine Management System (EMS):

The EMS controls the engine's fuel and ignition systems. There are several options:

- Reprogramming the Existing ECU: This is the cheapest option, but it requires expertise and might not be possible for all swaps.

- Standalone EMS: A standalone EMS offers maximum flexibility and control, but it's more complex to install and tune. Companies like Holley, AEM, and Megasquirt offer a variety of standalone EMS options.

- Wiring Harness: You'll need a wiring harness to connect the EMS to the engine and the vehicle's electrical system. You can either modify the existing harness or purchase a new, custom-built harness.

4. Fuel System:

Upgrading the fuel system is often necessary to supply enough fuel for the new engine.

- Fuel Pump: Choose a fuel pump with sufficient flow rate for the engine's horsepower.

- Fuel Injectors: Select injectors with the appropriate flow rate and impedance.

- Fuel Lines: Upgrade the fuel lines to handle the increased fuel pressure and flow.

- Fuel Pressure Regulator: An adjustable fuel pressure regulator allows you to fine-tune the fuel pressure.

5. Cooling System:

Overheating is a common problem with engine swaps, so ensuring adequate cooling is crucial.

- Radiator: Choose a radiator with sufficient cooling capacity for the new engine. An aluminum radiator is often a good upgrade.

- Cooling Fan: An electric cooling fan is more efficient than a mechanical fan.

- Hoses: Use high-quality hoses that can withstand the engine's temperature and pressure.

6. Exhaust System:

A custom exhaust system is often required to match the new engine.

- Headers/Exhaust Manifolds: Choose headers or exhaust manifolds that are designed for the specific engine and chassis.

- Catalytic Converters: If required for emissions compliance, choose high-flow catalytic converters.

- Mufflers: Select mufflers that provide the desired sound level and performance.

- Exhaust Tubing: Choose the appropriate diameter and material for the exhaust tubing.

7. Mounting and Fitment:

Addressing mounting and fitment issues is essential for a successful swap.

- Engine Mounts: Custom engine mounts are often required. You can either fabricate your own or purchase pre-made mounts.

- Transmission Mount: A new transmission mount might be needed to accommodate the new transmission.

- Clearance Issues: Address any clearance issues with the hood, firewall, or other components. This might require modifying the engine bay or using a different intake manifold.

8. Miscellaneous Parts:

Don't forget these often-overlooked parts:

- Fluids: Oil, coolant, transmission fluid, power steering fluid, brake fluid.

- Filters: Oil filter, fuel filter, air filter.

- Belts and Hoses: Replace all belts and hoses.

- Fasteners: Nuts, bolts, washers. Use high-quality fasteners.

- Sensors: Oxygen sensors, temperature sensors, pressure sensors.

- Wiring Supplies: Wire, connectors, heat shrink tubing.

Estimating Labor Costs: DIY vs. Professional Installation

Labor costs can be a significant portion of the overall expense. If you're performing the swap yourself, you'll save on labor, but you'll need to invest your time and potentially purchase specialized tools. If you're hiring a professional mechanic, get quotes from multiple shops and compare their hourly rates and estimated labor time. Be sure to factor in potential unforeseen issues that could increase labor costs. A realistic assessment of your own skills and available time is crucial.

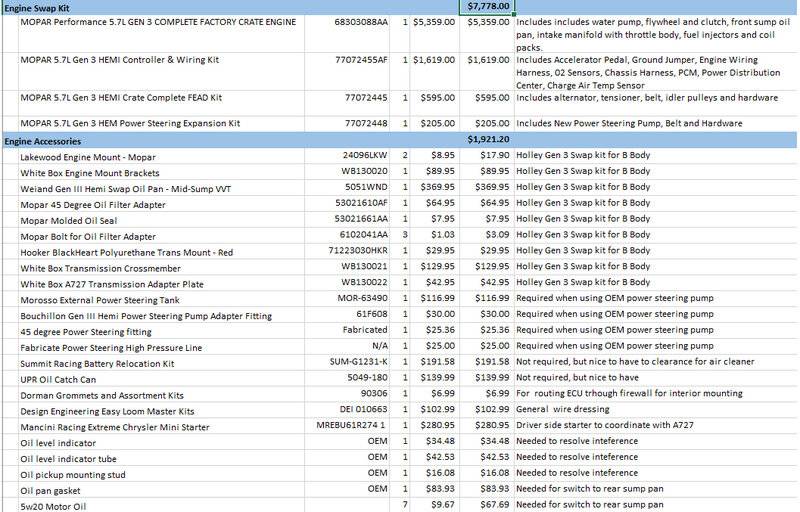

Creating a Spreadsheet: Organizing Your Costs

The best way to manage the parts list and cost analysis is to create a spreadsheet. Include columns for:

- Part Name

- Description

- Part Number

- Supplier

- Price

- Quantity

- Total Cost

- Notes

This will allow you to easily track your spending and identify areas where you can potentially save money. You can also use the spreadsheet to compare prices from different suppliers.

Contingency Planning: The "Unexpected Costs" Fund

Even with the most meticulous planning, engine swaps rarely go exactly as planned. There will inevitably be unexpected costs, such as damaged parts, missing components, or unforeseen fitment issues. It's wise to set aside a contingency fund of at least 10-15% of the total estimated cost to cover these unexpected expenses. This buffer will help prevent the project from stalling due to budget constraints.

Conclusion: Informed Decisions for a Successful Swap

Engine swaps are a rewarding, but complex undertaking. By taking the time to carefully define the scope of the swap, compile a detailed parts list, and accurately estimate the costs, you can significantly increase your chances of a successful and satisfying project. Remember, thorough planning and preparation are the keys to a budget-friendly and trouble-free engine swap.