Exhaust Kit Header Design And Backpressure Analysis

Upgrading your vehicle's exhaust system is a popular modification for enthusiasts seeking improved performance, enhanced sound, and a more aggressive look. A key component of any exhaust upgrade is the exhaust header and its design, and understanding the concept of backpressure is crucial for optimizing performance. This article delves into exhaust header design and its relationship with backpressure, providing insights for informed decisions.

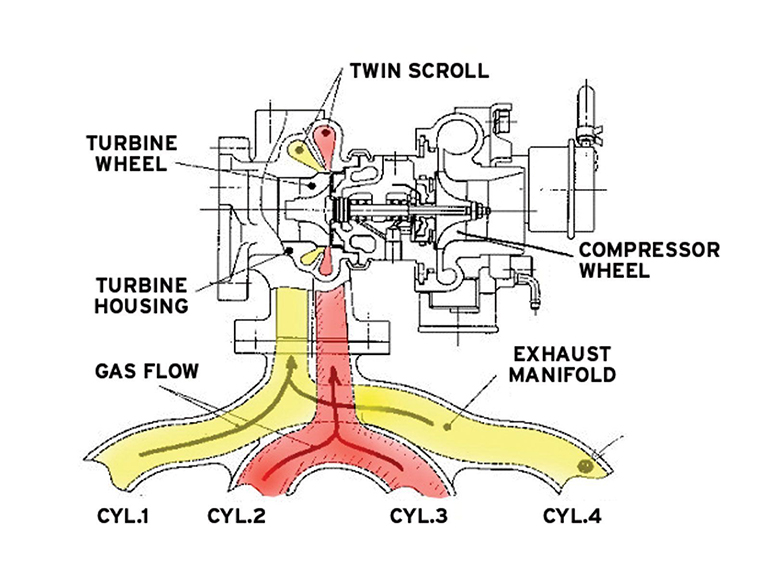

Understanding Exhaust Headers

Exhaust headers, also known as exhaust manifolds, are the first part of the exhaust system that collects exhaust gases from the engine's cylinders. Factory exhaust manifolds are often designed with cost-effectiveness and space constraints in mind, which can sometimes restrict exhaust flow. Aftermarket exhaust headers are designed to improve this flow, leading to potential performance gains.

Types of Exhaust Headers

There are primarily two types of exhaust headers:

- Tube Headers (or Tubular Headers): These headers use individual pipes (tubes) to direct exhaust gases from each cylinder to a common collector. They are known for their superior flow characteristics compared to cast manifolds.

- Cast Manifolds: These are typically found as stock equipment. They are more durable and less expensive to manufacture but generally offer less efficient exhaust flow.

Tube headers can be further divided into:

- Shorty Headers: These headers are shorter in length and primarily offer improved throttle response. They often retain the factory catalytic converters.

- Long Tube Headers (or Full-Length Headers): These headers feature longer tubes and are designed to maximize exhaust scavenging and increase horsepower, especially at higher RPMs. They often require modifications to the exhaust system to accommodate their length and the relocation of catalytic converters.

Exhaust Header Design Principles

The design of an exhaust header significantly impacts its performance. Key design factors include:

- Tube Diameter: The diameter of the header tubes must be appropriately sized for the engine. Tubes that are too small will restrict exhaust flow, while tubes that are too large can reduce exhaust velocity, leading to decreased scavenging. Generally, larger engines or engines operating at higher RPMs require larger diameter tubes.

- Tube Length: The length of the header tubes influences the engine's power band. Longer tubes tend to improve low-end torque, while shorter tubes favor high-RPM horsepower.

- Collector Design: The collector is where the individual header tubes merge. A well-designed collector minimizes turbulence and promotes smooth exhaust flow. Merge collectors, which smoothly transition the exhaust gases into a single pipe, are generally considered superior to simple, abrupt collectors.

- Material: Exhaust headers are typically made from stainless steel or mild steel. Stainless steel offers superior corrosion resistance and durability, while mild steel is more affordable. The thickness of the material also plays a role in durability, with thicker-walled headers being more resistant to cracking.

Backpressure: Friend or Foe?

Backpressure is the resistance to exhaust flow in the exhaust system. It's a common misconception that backpressure is always detrimental to performance. In reality, a certain amount of backpressure can be beneficial, especially in naturally aspirated engines.

Here's why:

- Scavenging Effect: Exhaust pulses create a vacuum effect in the cylinder as the exhaust valve opens. This effect, known as scavenging, helps to draw out exhaust gases and pull in the intake charge. The amount of backpressure in the exhaust system can influence the scavenging effect.

- Low-End Torque: A small amount of backpressure can improve low-end torque by maintaining exhaust gas velocity and promoting scavenging at lower engine speeds.

However, excessive backpressure is always detrimental. It restricts exhaust flow, increases pumping losses (the energy required to push exhaust gases out of the cylinder), and reduces overall engine efficiency. This is where properly designed headers and exhaust systems come into play.

Understanding the Relationship between Headers and Backpressure

The design of the exhaust header directly affects the amount of backpressure in the system. Headers with smaller diameter tubes, sharp bends, or poorly designed collectors will increase backpressure. Conversely, headers with larger diameter tubes, smooth bends, and efficient collectors will reduce backpressure.

The ideal amount of backpressure depends on the engine's characteristics and intended use. For example:

- Street Cars: A moderate amount of backpressure is often desirable to maintain good low-end torque and drivability. Shorty headers or well-designed long tube headers with appropriately sized tubing can be suitable.

- Race Cars: Race cars prioritize high-RPM horsepower, and minimizing backpressure is crucial. Long tube headers with large diameter tubes and merge collectors are typically used.

- Turbocharged Engines: Turbocharged engines generally benefit from minimal backpressure in the exhaust system after the turbocharger. The turbocharger itself creates significant backpressure, so reducing it downstream can improve turbocharger efficiency and overall performance.

Analyzing and Measuring Backpressure

Measuring backpressure can help you determine if your exhaust system is performing optimally. This can be done using a backpressure gauge, which is typically connected to a port in the exhaust manifold or header.

Here's a general guideline for acceptable backpressure levels (measured at the exhaust manifold):

- Naturally Aspirated Engines: Generally, backpressure should be kept below 2-3 PSI at peak RPM.

- Turbocharged Engines: Backpressure should be as low as possible, ideally below 1 PSI. Higher backpressure can significantly reduce turbocharger efficiency.

It's important to note that these are just general guidelines, and the ideal backpressure level can vary depending on the engine and its specific application. Consulting with a performance specialist or engine tuner is recommended for precise backpressure optimization.

Choosing the Right Exhaust Header

Selecting the right exhaust header requires careful consideration of your vehicle's engine, intended use, and budget. Here's a step-by-step approach:

- Determine Your Goals: Are you primarily interested in improved throttle response, low-end torque, or high-RPM horsepower? This will help you narrow down your header choices.

- Consider Your Engine: Larger engines and engines operating at higher RPMs generally require larger diameter header tubes.

- Research Different Brands and Models: Read reviews and compare specifications to find headers that are known for their quality, performance, and fitment.

- Check for Compatibility: Ensure that the header is compatible with your vehicle's make, model, and year.

- Factor in Installation: Header installation can be complex and may require professional assistance. Consider the cost of installation when budgeting for your exhaust upgrade.

- Consider Material: Stainless steel headers offer better corrosion resistance and longevity but come at a higher price point. Mild steel headers are a more budget-friendly option.

Conclusion

Understanding exhaust header design and the concept of backpressure is essential for optimizing your vehicle's performance. By carefully considering your engine's characteristics and intended use, you can choose the right exhaust header to achieve your desired results. Remember that minimizing excessive backpressure is crucial for maximizing engine efficiency and horsepower. Always consult with a qualified mechanic or performance specialist to ensure proper installation and tuning for optimal performance gains. With the right header and a well-designed exhaust system, you can unlock your vehicle's true potential.

Investing in a good quality exhaust header can provide significant improvements in engine performance. From enhanced throttle response to increased horsepower, the benefits of a well-designed header are undeniable. However, remember that proper installation and tuning are crucial for maximizing these benefits and ensuring optimal engine performance. Do your research, consult with experts, and choose wisely to unlock your vehicle's full potential.