Fuel Injector Flow Rates And Spray Pattern Analysis

Alright folks, let's dive deep into the heart of your fuel system: the fuel injector. We're going to talk about two crucial characteristics – flow rate and spray pattern – and how understanding them can dramatically improve your engine's performance, efficiency, and longevity. Think of this as a calibration guide for your engine's appetite.

Fuel Injector Flow Rate: Delivering the Right Dosage

Flow rate, simply put, is the amount of fuel an injector can deliver in a given time. It's usually measured in pounds per hour (lb/hr) or cubic centimeters per minute (cc/min). For example, a 30 lb/hr injector can theoretically spray 30 pounds of fuel in one hour when fully open at its rated fuel pressure.

Why is Flow Rate Important?

Getting the correct flow rate is critical for maintaining the air-fuel ratio (AFR). This ratio is the balance between air and fuel entering the engine cylinders. A stoichiometric AFR, typically around 14.7:1 for gasoline, ensures complete combustion, maximizing efficiency and minimizing emissions. Too much fuel (rich condition) can lead to decreased power, poor fuel economy, and increased emissions. Too little fuel (lean condition) can cause engine knocking, overheating, and potentially catastrophic engine damage.

When you modify your engine – say, adding a turbocharger, supercharger, or performing significant head work – you increase its air intake. To maintain the ideal AFR, you need to increase the fuel delivery as well. This is where larger fuel injectors come into play. Choosing the correct injector size for your modifications is non-negotiable.

Calculating Your Required Injector Size

There are various formulas and online calculators that can help you estimate the appropriate injector size. These generally consider:

- Horsepower Goal: Your target horsepower is the primary driver of fuel demand.

- Brake Specific Fuel Consumption (BSFC): This is a measure of engine efficiency. Naturally aspirated engines typically have a BSFC around 0.5 lb/hp/hr, while forced induction engines can range from 0.55 to 0.65 lb/hp/hr or even higher. Consult your engine builder for a more precise estimate.

- Number of Injectors: This is typically the number of cylinders in your engine.

- Injector Duty Cycle: This is the percentage of time the injector is open and spraying fuel. A safe maximum duty cycle is around 80-85%. Running injectors at 100% duty cycle can lead to overheating, inconsistent fuel delivery, and injector failure.

- Fuel Pressure: The pressure at which fuel is delivered to the injectors. Aftermarket fuel systems often run at higher pressures.

The basic formula looks something like this (this is a simplified version; use online calculators for precise results):

Injector Size (lb/hr) = (Target HP * BSFC) / (Number of Injectors * Max Duty Cycle)Example: If you're aiming for 400 horsepower with a turbocharged four-cylinder engine, a BSFC of 0.6 lb/hp/hr, and a maximum duty cycle of 80%, the calculation would be:

Injector Size = (400 * 0.6) / (4 * 0.8) = 75 lb/hrTherefore, you'd need injectors capable of flowing at least 75 lb/hr. Always round *up* slightly for a margin of safety.

Static vs. Dynamic Flow Rate

It's crucial to understand the difference between static and dynamic flow rates. Static flow rate refers to the injector's flow when it's continuously open. Dynamic flow rate refers to the injector's flow under real-world operating conditions, where it's rapidly opening and closing. Dynamic flow is affected by the injector's opening and closing times (dead time or latency). Accurate injector data, especially dead time information, is crucial for properly calibrating your ECU (Engine Control Unit).

Fuel Injector Spray Pattern: Atomization is Key

While flow rate determines *how much* fuel is delivered, the spray pattern determines *how well* that fuel is atomized and distributed within the combustion chamber. Poor atomization leads to incomplete combustion, reduced power, increased emissions, and potential engine damage.

What Makes a Good Spray Pattern?

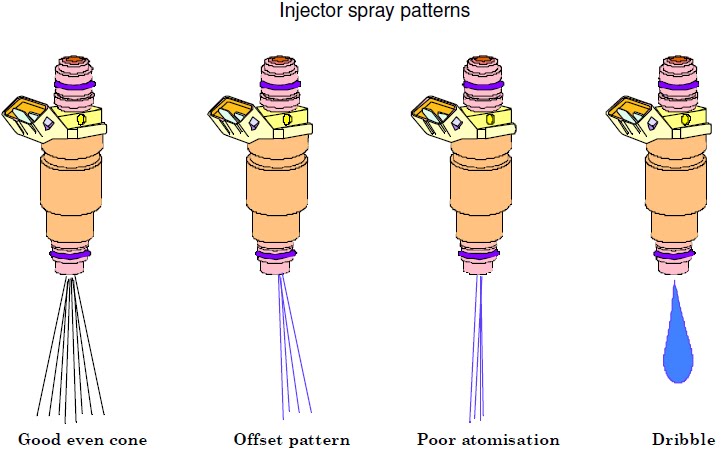

An ideal spray pattern consists of finely atomized fuel droplets evenly distributed throughout the combustion chamber. This ensures that each fuel droplet has sufficient surface area to mix with air and burn completely. Key characteristics of a good spray pattern include:

- Fine Atomization: The fuel should be broken down into very small droplets, resembling a fine mist.

- Uniform Distribution: The spray should be evenly dispersed across the target area (intake valve or combustion chamber).

- Consistent Cone Angle: The spray should form a consistent cone shape, avoiding concentrated streams or "wet spots."

- Absence of Dripping or Streamers: The injector should shut off cleanly, without any fuel dripping or streaming after the pulse ends.

Factors Affecting Spray Pattern

Several factors can influence the spray pattern of a fuel injector:

- Injector Design: Different injector designs (e.g., pintle, disc, multi-hole) produce different spray patterns. Multi-hole injectors generally offer better atomization and distribution, especially in modern engines.

- Fuel Pressure: Increasing fuel pressure can improve atomization, but excessively high pressure can lead to injector wear.

- Fuel Temperature: Fuel temperature affects viscosity, which in turn affects atomization.

- Injector Condition: Clogged or dirty injectors can produce distorted spray patterns, leading to uneven fuel distribution and poor engine performance.

- Voltage: Low voltage can affect the injector's opening time and spray pattern.

Analyzing Your Spray Pattern

You can visually inspect the spray pattern of your fuel injectors using a dedicated injector cleaning and testing rig. These rigs typically consist of a pressurized fuel reservoir, a test chamber, and a power source to activate the injectors. The process usually involves:

- Removing the Injectors: Carefully remove the injectors from your engine, labeling them to ensure you reinstall them in the same locations.

- Cleaning the Injectors: Clean the injectors using an ultrasonic cleaner and injector cleaning solution. This removes any deposits that may be obstructing the fuel flow.

- Testing the Spray Pattern: Mount the injectors on the test rig and activate them. Observe the spray pattern closely. Look for any signs of dripping, streamers, uneven distribution, or poor atomization.

- Comparing to a Known Good Injector: If possible, compare the spray pattern of your injectors to a new or refurbished injector. This will help you identify any deviations from the ideal pattern.

If you observe any issues with your spray pattern, it's time to either clean the injectors more thoroughly or replace them. A bad spray pattern is a clear sign of a malfunctioning injector.

The Role of Injector Dynamics Data

Modern ECUs require detailed injector dynamics data to accurately control fuel delivery. This data includes:

- Battery Voltage Offset (Dead Time/Latency): The time it takes for the injector to fully open and close, which varies with voltage.

- Short Pulse Width Adder: Adjustments needed for very short injector pulses.

- Flow Rate vs. Pressure: How flow changes with fuel pressure.

Accurate injector dynamics data is crucial for a smooth idle, consistent AFR, and overall drivability. This data is often provided by the injector manufacturer and must be entered into your ECU's tuning software. Using incorrect injector data can lead to significant fueling errors.

Putting it All Together: A Holistic Approach

Understanding both flow rate and spray pattern is essential for optimizing your fuel system. Don't just focus on one or the other. Choosing the right injector size ensures you have enough fuel for your power goals, while a proper spray pattern ensures that fuel is delivered efficiently and effectively. By paying attention to these details, you can unlock the full potential of your engine and enjoy a smoother, more powerful, and more reliable driving experience.

Remember to always consult with experienced tuners and engine builders for guidance specific to your engine setup. They can provide valuable insights and ensure you're making the right choices for your application. Happy tuning!