Greddy Exhaust System Backpressure And Flow Characteristics

Upgrading your exhaust system is a common modification for car enthusiasts seeking performance gains, a more aggressive sound, and enhanced aesthetics. Among the many brands available, GReddy stands out as a reputable manufacturer known for its high-quality exhaust systems. However, understanding the concepts of backpressure and flow characteristics is crucial to making an informed decision about whether a GReddy exhaust, or any aftermarket exhaust, is right for your vehicle.

Understanding Exhaust Backpressure

Backpressure, in the context of an exhaust system, refers to the resistance that exhaust gases encounter as they flow from the engine's cylinders, through the exhaust manifold or header, catalytic converter (if equipped), resonators, mufflers, and finally, out of the tailpipe. It's essentially a measure of how difficult it is for the engine to expel the exhaust gases.

For a long time, a common misconception persisted that some level of backpressure was absolutely necessary for an engine to run efficiently, particularly at lower RPMs. The reasoning was that backpressure helped retain some exhaust gases in the cylinder, aiding in scavenging and improving low-end torque. While there's a grain of truth to this, the reality is more nuanced. Excessive backpressure is detrimental to engine performance.

When an engine has to work harder to push exhaust gases out, it loses power. This is because the engine spends energy overcoming the resistance instead of using it to generate horsepower. Increased backpressure also leads to higher exhaust gas temperatures (EGTs), which can stress engine components and potentially lead to damage over time. Furthermore, it can negatively impact fuel efficiency.

Conversely, too little backpressure, which can occur with excessively large exhaust piping, isn't ideal either. While high-RPM power may improve, low-end torque can suffer. This is because the scavenging effect, where the exiting exhaust gases help pull the next intake charge into the cylinder, is diminished. A properly designed exhaust system aims to strike a balance between minimizing backpressure for optimal performance and maintaining sufficient scavenging for good low-end response.

Exhaust Flow Characteristics: The Importance of Scavenging

Exhaust flow characteristics refer to the overall efficiency and effectiveness with which exhaust gases are removed from the engine. This encompasses not just the minimization of backpressure, but also the optimization of the scavenging effect. Scavenging is the process where the outgoing exhaust pulse helps to draw the incoming air-fuel mixture into the cylinder. This creates a more complete combustion cycle, leading to improved power and efficiency.

Several factors influence exhaust flow characteristics, including:

- Piping Diameter: Larger diameter piping generally reduces backpressure, allowing for increased flow. However, excessively large piping can reduce exhaust velocity, diminishing the scavenging effect.

- Piping Material: Materials like stainless steel offer smoother internal surfaces compared to mild steel, reducing friction and improving flow.

- Mandrel Bends: Mandrel bending maintains a consistent diameter throughout the bend, unlike crush bending, which restricts flow.

- Muffler Design: Mufflers play a crucial role in reducing exhaust noise, but their design can also impact flow. Straight-through mufflers generally offer better flow than chambered mufflers.

- Catalytic Converter Design: High-flow catalytic converters minimize flow restriction while still effectively reducing emissions.

GReddy Exhaust Systems: Balancing Backpressure and Flow

GReddy exhaust systems are designed with a focus on optimizing both backpressure and flow. They strive to achieve a balance that delivers improved performance without sacrificing low-end torque or causing excessive noise.

Here's how GReddy approaches this:

- Piping Diameter Selection: GReddy carefully selects the appropriate piping diameter for each application. They consider the engine's displacement, horsepower output, and intended use to ensure optimal flow without sacrificing scavenging.

- High-Quality Materials: Many GReddy exhaust systems are constructed from high-quality stainless steel, which offers excellent durability and corrosion resistance, as well as a smoother internal surface for improved flow.

- Mandrel Bending: GReddy utilizes mandrel bending techniques to ensure smooth, unrestricted flow throughout the exhaust system.

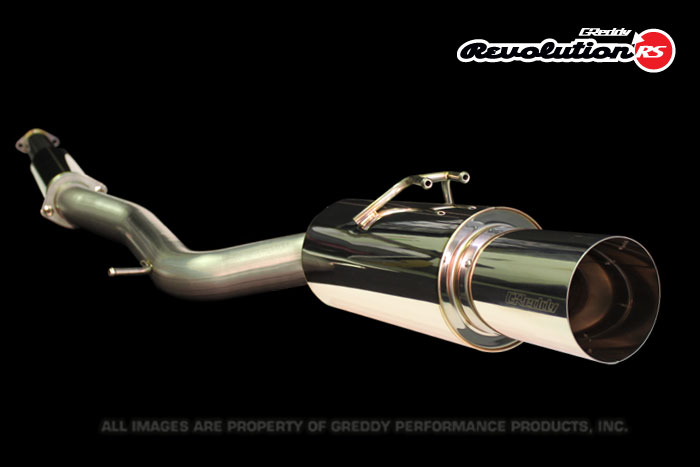

- Muffler Design: GReddy offers a variety of muffler designs, including straight-through and chambered options, to cater to different noise level preferences and performance requirements. They often use their own proprietary muffler designs aimed at maximizing flow while maintaining a desired sound profile.

- Catalytic Converters (Where Applicable): When catalytic converters are included, GReddy often utilizes high-flow designs to minimize flow restriction.

It's important to note that the specific design and flow characteristics of a GReddy exhaust system will vary depending on the vehicle application. A GReddy exhaust designed for a turbocharged engine will likely have different characteristics than one designed for a naturally aspirated engine. Turbocharged engines typically benefit from exhaust systems with lower backpressure, as the turbocharger itself creates backpressure.

Choosing the Right GReddy Exhaust for Your Needs

When selecting a GReddy exhaust system, consider the following factors:

- Your Vehicle: Ensure that the exhaust system is specifically designed for your vehicle's make, model, and year.

- Engine Modifications: If you have other engine modifications, such as an aftermarket intake or ECU tune, choose an exhaust system that complements those modifications.

- Intended Use: Consider how you primarily use your vehicle. If it's a daily driver, you may want to prioritize a system that offers a balance of performance and noise. If it's a dedicated track car, you may be willing to sacrifice some noise comfort for maximum performance.

- Sound Preference: GReddy offers a range of exhaust systems with varying sound levels. Listen to sound clips online or in person to get a sense of the sound profile you prefer.

- Budget: GReddy exhaust systems vary in price depending on the materials, design, and complexity. Set a budget before you start shopping.

Installation and Tuning Considerations

While many GReddy exhaust systems are designed to be direct bolt-on replacements for the factory exhaust, professional installation is always recommended, especially if you lack experience with automotive modifications. A qualified mechanic can ensure that the exhaust system is properly installed and that all connections are secure.

In some cases, installing an aftermarket exhaust system may require or benefit from ECU tuning. An ECU tune can optimize the engine's air-fuel ratio and ignition timing to take full advantage of the increased exhaust flow. This can result in even greater performance gains.

Conclusion

GReddy exhaust systems are a popular choice for car enthusiasts seeking improved performance, enhanced sound, and a stylish appearance. By understanding the principles of backpressure and flow characteristics, you can make an informed decision about whether a GReddy exhaust is the right choice for your vehicle. Remember to consider your vehicle's specific needs, your intended use, and your personal preferences when selecting an exhaust system. Research thoroughly, compare different options, and consult with qualified professionals to ensure a successful and satisfying upgrade.

Ultimately, a properly designed and installed GReddy exhaust system can provide a noticeable improvement in your vehicle's performance and driving experience. However, remember that individual results may vary depending on the specific vehicle, engine modifications, and driving conditions. Always prioritize safety and consult with qualified professionals before making any modifications to your vehicle.

Investing in a quality exhaust system like GReddy can be a significant upgrade, but understanding its impact on backpressure and flow is key to maximizing its benefits.