Installation And Fitment Guide For S13 Overfender Panels

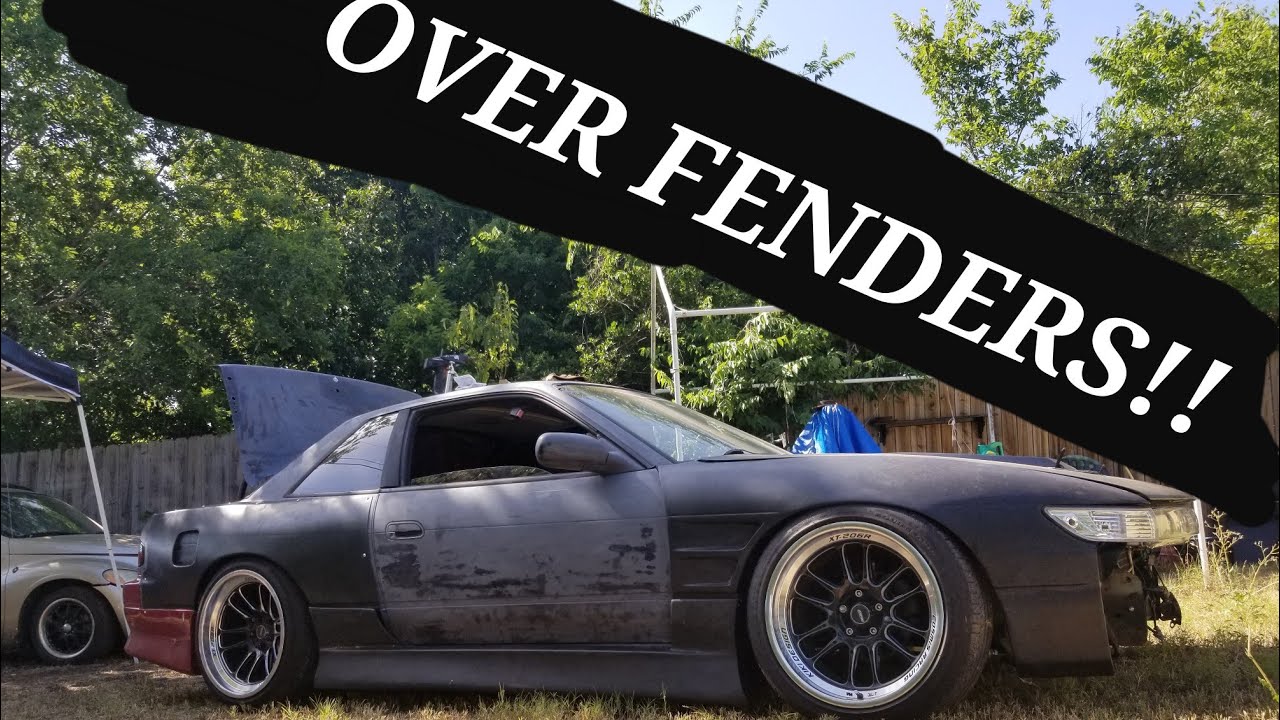

So, you've decided to embrace the wider world of overfenders on your S13. Good choice! Overfenders are a common modification to the Nissan 240SX (S13 chassis) platform, providing the necessary clearance for wider wheels and tires, essential for enhanced grip and a more aggressive aesthetic. However, unlike bolt-on accessories, installing and fitting overfenders is a meticulous process requiring patience, skill, and a thorough understanding of bodywork. This guide will walk you through the process, from initial assessment to final fitment, highlighting the key considerations and potential pitfalls.

I. Initial Assessment and Preparation

Before you even think about grabbing a wrench, a proper assessment is crucial. This involves understanding the condition of your existing fenders, the type of overfenders you've chosen, and gathering the necessary tools and materials. The quality of this initial preparation directly influences the final outcome.

1.1 Fender Condition and Rust Repair

Carefully inspect your existing fenders for rust, dents, and other damage. Rust is a particularly insidious problem, as it can spread under the overfender, leading to further corrosion. Address any rust issues before proceeding. This may involve cutting out affected areas, welding in new metal patches, and applying rust inhibitors and protective coatings. Ignoring rust will only exacerbate the problem down the line, potentially compromising the structural integrity of the fender and the fitment of the overfender.

Dents and imperfections should also be addressed as much as possible. While the overfender will cover these up to an extent, significant damage can interfere with the overfender's mounting surface and create unwanted gaps. Using body fillers and sanding techniques, strive to achieve a relatively smooth and even surface before moving on.

1.2 Overfender Type and Material

Overfenders are typically made from fiberglass (FRP) or polyurethane (PU). FRP is generally more rigid and can offer a sharper, more defined look, but it's also more brittle and prone to cracking upon impact. PU is more flexible and impact-resistant but can be more difficult to work with during initial fitment and may require more extensive surface preparation. Be aware of the material's inherent properties before starting work. Furthermore, are they designed to require fender trimming or are they full replacement quarter panels?

Additionally, consider the design and fitment of the overfender itself. Some overfenders are designed to be "bolt-on" (though often requiring extensive modification), while others are designed to be bonded to the existing fender. Check the manufacturer's instructions and understand the intended installation method.

1.3 Tools and Materials

Gather the following tools and materials:

- Safety Equipment: Safety glasses, dust mask, gloves

- Cutting Tools: Angle grinder with cutting discs, reciprocating saw (Sawzall), metal nibbler (optional)

- Grinding/Sanding Tools: Angle grinder with grinding discs, orbital sander, sanding blocks (various grits)

- Welding Equipment (if necessary): MIG or TIG welder, welding helmet, welding gloves

- Bodywork Tools: Body filler, spreader, hammer and dolly set (for dent repair), body files

- Fasteners: Self-tapping screws, rivets, panel bond adhesive (depending on installation method)

- Measuring Tools: Tape measure, straight edge, markers

- Miscellaneous: Masking tape, sandpaper (various grits), cleaning solvents (e.g., wax and grease remover), primer, paint (optional), undercoating

II. Cutting and Trimming the Existing Fenders

This is arguably the most critical step, and irreversible. Careful planning and execution are paramount. The extent of cutting depends on the width of the overfender and the desired ride height and wheel/tire setup. The goal is to create enough clearance for the wheels and tires to move freely without rubbing, while also providing a solid mounting surface for the overfender.

2.1 Marking the Cut Lines

With the overfender loosely positioned against the fender, use a marker to trace the outline of the desired cut line. Remember to err on the side of caution – it's always easier to remove more material than to add it back. Consider the inner lip of the existing fender as this will most likely need to be cut and folded to allow for tire clearance. Think about the suspension travel; you don't want the tires to hit the inner fenders during compressions.

Pro Tip: Use masking tape to protect the surrounding paint from scratches and accidental cuts. Multiple layers of tape can provide a significant barrier.

2.2 Cutting the Fender

Using your chosen cutting tool (angle grinder, reciprocating saw, or metal nibbler), carefully cut along the marked lines. If using an angle grinder, take your time and use a slow, controlled motion to avoid overheating the metal and warping the fender. A reciprocating saw is often better for larger, straighter cuts, while a metal nibbler offers precise control for intricate shapes. Always wear safety glasses and a dust mask to protect yourself from flying debris. Remember to take breaks and allow the metal to cool to prevent warping.

2.3 Deburring and Smoothing the Cut Edges

After cutting, the edges of the fender will be sharp and uneven. Use a grinding disc to deburr and smooth the cut edges. This prevents injuries and provides a better surface for the overfender to mount against. Pay close attention to any sharp corners or projections, as these can cause stress points that lead to cracking in the overfender. Sanding the edges smooth will further improve the fit and finish. Use a file to clean up the edge.

2.4 Folding or Removing the Inner Lip

In most cases, the inner lip of the fender will need to be either folded inwards or completely removed to provide adequate tire clearance. Folding the lip can be done with a hammer and dolly set, but be careful not to damage the outer fender. Removing the lip requires further cutting and grinding. Regardless of the method, ensure the remaining edge is smooth and free of sharp edges.

III. Test Fitting and Adjusting the Overfender

With the fenders cut and prepped, it's time to test fit the overfender. This is where you'll identify any areas that need further adjustment or modification.

3.1 Positioning and Securing the Overfender

Carefully position the overfender against the modified fender. Use clamps or temporary fasteners (e.g., self-tapping screws) to hold it in place. Step back and visually inspect the fit from all angles. Look for any gaps, misalignment, or areas where the overfender contacts the body in an undesirable way.

3.2 Addressing Fitment Issues

Common fitment issues include:

- Gaps: Gaps can be caused by uneven cutting, warping of the fender, or imperfections in the overfender itself. Small gaps can be filled with body filler or panel bond adhesive. Larger gaps may require more extensive modifications, such as welding in metal shims or reshaping the overfender with heat.

- Misalignment: Misalignment can occur if the overfender doesn't align properly with the body lines of the car. This may require adjusting the mounting points or reshaping the overfender.

- Contact Points: Areas where the overfender rubs against the body can cause damage to the paint and potentially compromise the fit. Identify these contact points and address them by either removing material from the overfender or adjusting the fender itself.

3.3 Modifying the Overfender

Modifying an FRP or PU overfender requires different techniques. FRP can be sanded and reshaped relatively easily, but it's important to avoid overheating the material, as this can cause it to warp or crack. PU can be heated with a heat gun and reshaped, but it's important to avoid overheating the material, as this can cause it to melt or become brittle. Using specialized plastic welding equipment might be needed for PU repairs.

IV. Final Installation and Finishing

Once you're satisfied with the fitment, it's time to permanently install the overfender.

4.1 Choosing an Attachment Method

The attachment method depends on the type of overfender and your personal preference. Common methods include:

- Self-Tapping Screws: A relatively simple and inexpensive method, but it can be less secure and aesthetically pleasing.

- Rivets: More secure than self-tapping screws and can provide a cleaner look.

- Panel Bond Adhesive: Provides a strong and seamless bond, but requires careful surface preparation and can be difficult to remove if necessary.

- Welding: The strongest and most permanent method, but requires welding skills and can damage the paint. (Primarily applicable to metal overfenders or extensive modifications)

4.2 Surface Preparation

Regardless of the attachment method, proper surface preparation is essential for a strong and durable bond. Clean the mating surfaces of both the fender and the overfender with a wax and grease remover. Sand the surfaces to create a rough texture that the adhesive or fastener can grip onto. If using panel bond adhesive, follow the manufacturer's instructions carefully.

4.3 Applying Fasteners or Adhesive

Apply the chosen fasteners or adhesive according to the manufacturer's instructions. Ensure that the overfender is securely attached to the fender. Allow the adhesive to cure completely before proceeding to the next step.

4.4 Finishing Touches

Once the overfender is installed, you can blend it in with the existing bodywork. This may involve filling any remaining gaps with body filler, sanding the entire surface smooth, and applying primer and paint. Undercoating the inside of the fender will help prevent rust and corrosion. Remember to seam seal any gaps between the new and existing panels.

Installing overfenders is a significant undertaking that requires patience, skill, and attention to detail. By following these steps and understanding the key considerations, you can achieve a professional-looking result that enhances the performance and aesthetics of your S13.