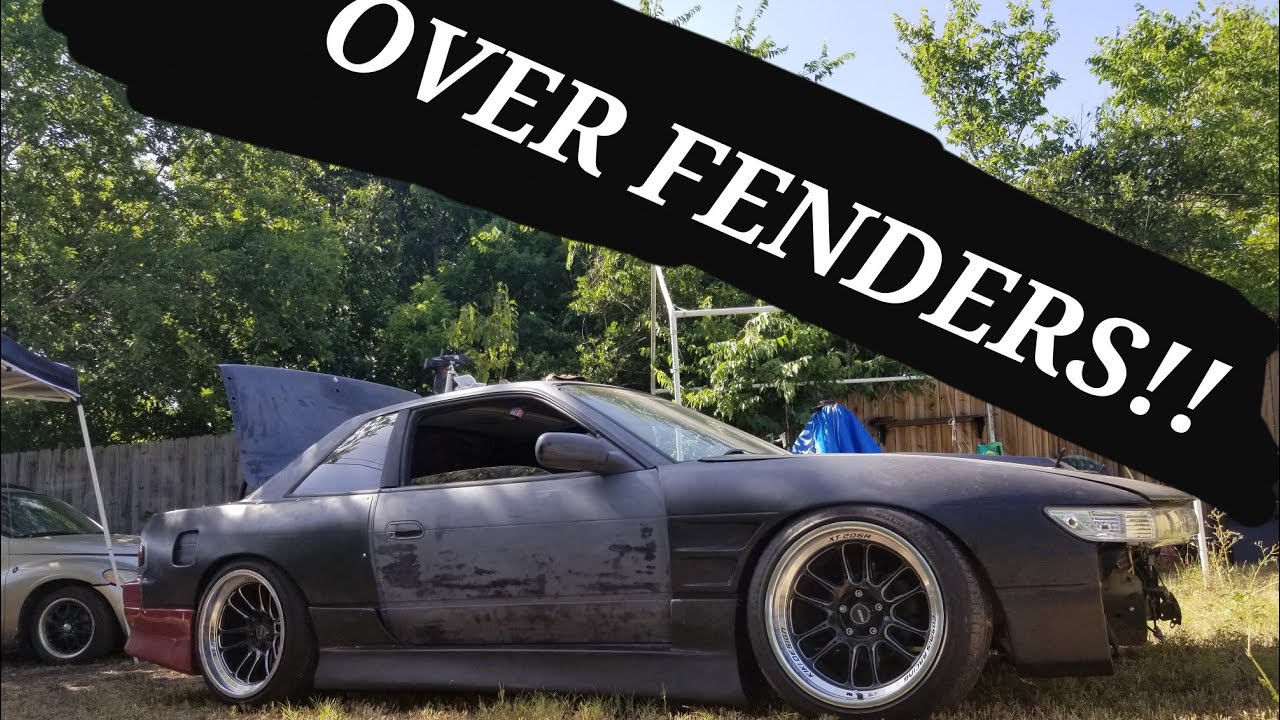

Installation And Fitment Of Front Overfenders On A Nissan 240sx

Installation and Fitment of Front Overfenders on a Nissan 240SX

The Nissan 240SX, known for its sleek design and drift-friendly nature, is a popular platform for modifications. One common upgrade is the installation of front overfenders. Overfenders not only enhance the vehicle's aesthetics but also allow for wider wheels and tires, improving grip and handling. This comprehensive guide provides a detailed walkthrough of the installation and fitment process, ensuring a professional-looking result.

Understanding Overfenders: Benefits and Considerations

Before diving into the installation, it's crucial to understand the purpose and benefits of overfenders. Overfenders are wider fender replacements that bolt or are molded onto the existing fenders. They serve several key functions:

- Increased Wheel Clearance: Overfenders provide the necessary clearance for running wider wheels and tires, allowing for improved traction and a more aggressive stance.

- Enhanced Aesthetics: They significantly alter the vehicle's appearance, giving it a wider, more aggressive look.

- Improved Aerodynamics: Some overfender designs can contribute to improved aerodynamics, though the impact is often minimal on street cars.

However, there are also considerations to keep in mind:

- Body Modification: Installing overfenders often requires cutting or modifying the original fenders, which is irreversible.

- Fitment Challenges: Achieving proper fitment can be time-consuming and may require adjustments.

- Cost: Overfenders themselves, along with the necessary tools and potential professional installation fees, can be a significant investment.

Tools and Materials Needed

Gathering the right tools and materials is essential for a smooth and successful installation. Here's a comprehensive list:

- Overfender Kit: Choose a reputable brand known for quality and fitment. Ensure the kit is specifically designed for the Nissan 240SX.

- Safety Glasses and Gloves: Protect your eyes and hands throughout the process.

- Masking Tape: To protect the surrounding paint and provide guidelines for cutting.

- Measuring Tape and Marker: For accurate measurements and marking cut lines.

- Cutting Tool: Angle grinder with cutting wheel, reciprocating saw, or body saw. A plasma cutter can be helpful for precise cuts.

- Grinding Tool: Angle grinder with flap disc or sanding disc to smooth cut edges.

- Drill and Drill Bits: For drilling mounting holes.

- Rivets or Bolts: Depending on the overfender design, you'll need rivets or bolts for secure attachment. Stainless steel hardware is recommended.

- Riveter or Wrench Set: To install the rivets or bolts.

- Body Filler (Optional): For filling gaps and imperfections.

- Sandpaper (Various Grits): For smoothing body filler.

- Primer: To prepare the surface for paint.

- Paint (Matching Color): To paint the overfenders to match the vehicle.

- Clear Coat: To protect the paint and provide a glossy finish.

- Jack and Jack Stands: To safely lift the vehicle.

- Wheel Chocks: To prevent the vehicle from rolling.

Step-by-Step Installation Guide

Follow these steps carefully for a successful overfender installation:

- Preparation:

- Park the 240SX on a level surface and engage the parking brake.

- Use wheel chocks to secure the rear wheels.

- Loosen the lug nuts on the front wheels.

- Jack up the front of the vehicle and securely support it with jack stands.

- Remove the front wheels.

- Test Fitment:

- Carefully position the overfender against the existing fender to assess the fitment.

- Identify any areas that require trimming or modification.

- Use masking tape to mark the areas that need to be cut.

- Cutting the Original Fender:

- This is a critical step, so proceed with caution.

- Use a cutting tool to carefully cut along the marked lines on the original fender. Start with small cuts and gradually remove more material as needed.

- Leave about 1-2 inches of the original fender for rigidity and attachment points.

- Be extremely careful not to damage any wiring, brake lines, or other components behind the fender.

- Grinding and Smoothing:

- Use a grinding tool to smooth the cut edges of the original fender.

- Remove any sharp edges or burrs to prevent injury and ensure a clean finish.

- Apply rust preventative paint to the freshly cut metal edges.

- Overfender Fitment and Adjustment:

- Position the overfender against the modified fender again.

- Check the alignment and fitment.

- Make any necessary adjustments by trimming or sanding the overfender.

- Pay close attention to the gap between the overfender and the door, as this is a common area for fitment issues.

- Drilling Mounting Holes:

- Once you're satisfied with the fitment, use a drill to create mounting holes in the overfender and the original fender.

- Use the overfender as a template for drilling the holes in the original fender.

- Ensure the holes are properly aligned and spaced evenly.

- Attaching the Overfender:

- Secure the overfender to the original fender using rivets or bolts.

- If using rivets, use a riveter to securely fasten them.

- If using bolts, tighten them securely with a wrench.

- Apply sealant or silicone around the mounting points to prevent water intrusion.

- Bodywork (Optional):

- If there are any gaps or imperfections between the overfender and the body, use body filler to smooth them out.

- Sand the body filler smooth with progressively finer grits of sandpaper.

- Painting:

- Clean the overfender thoroughly.

- Apply primer to the overfender and any areas where body filler was used.

- Sand the primer smooth with fine-grit sandpaper.

- Apply several coats of paint, allowing each coat to dry completely before applying the next.

- Apply clear coat to protect the paint and provide a glossy finish.

- Reassembly:

- Reinstall the front wheels.

- Lower the vehicle back to the ground.

- Tighten the lug nuts to the manufacturer's specifications.

Troubleshooting Common Issues

Even with careful planning and execution, you may encounter some challenges during the installation process. Here are some common issues and how to address them:

- Poor Fitment: If the overfender doesn't fit properly, double-check the alignment and make sure you haven't missed any steps. Minor adjustments can often be made by trimming or sanding the overfender. For more significant fitment issues, consult with a professional body shop.

- Gaps and Imperfections: Gaps between the overfender and the body can be filled with body filler. Take your time and apply the filler in thin layers, allowing each layer to dry completely before sanding.

- Rust: Cutting the original fender exposes bare metal, which is susceptible to rust. Apply rust preventative paint to the cut edges to protect them.

- Vibrations: If the overfender vibrates or rattles after installation, check the mounting points and make sure they are securely fastened. You may need to add additional mounting points or use thicker rivets or bolts.

Professional Installation vs. DIY

Installing overfenders can be a challenging and time-consuming project. If you're not comfortable with bodywork or don't have the necessary tools and experience, it's best to consider professional installation. A professional body shop will have the expertise and equipment to ensure a high-quality, long-lasting result. However, DIY installation can save you money if you're willing to invest the time and effort. Weigh the pros and cons carefully before making a decision.

Final Thoughts

Installing front overfenders on a Nissan 240SX is a popular modification that can significantly enhance the vehicle's appearance and performance. By following this comprehensive guide and taking your time, you can achieve a professional-looking result. Remember to prioritize safety, use the right tools and materials, and don't hesitate to seek professional help if needed. With careful planning and execution, you can transform your 240SX into a head-turning machine.