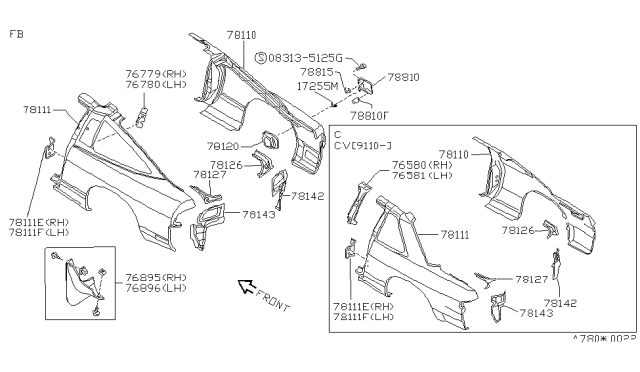

Installation Guide For Rear Over-fenders On A Nissan 240sx

So, you've decided to tackle rear over-fenders on your Nissan 240SX. Excellent choice! Over-fenders can dramatically change the look of your S-chassis, allowing for wider wheels and a more aggressive stance. This guide is designed to walk you through the process, whether you're prepping for a track day or just want a more unique look.

Before we dive in, understand that this isn't a simple bolt-on procedure. It typically involves cutting, trimming, and potentially welding, depending on the type of over-fenders you've chosen. Patience and careful planning are your best friends here. Rushing can lead to a less-than-desirable final result.

Planning & Preparation

First and foremost, verify the fitment of your over-fenders. Hold them up to your car and ensure they align reasonably well with the existing body lines. Minor adjustments are expected, but significant discrepancies could indicate an incorrect part or a fabrication issue. It's much easier to return them *before* you start cutting!

Next, gather your tools. Here's a comprehensive list:

- Safety Glasses & Gloves: Absolutely essential!

- Respirator/Dust Mask: Cutting fiberglass or metal generates harmful particles.

- Measuring Tape & Marking Pen: For precise cuts and placement.

- Angle Grinder with Cutting Discs: For cutting the existing quarter panel. A 4.5" grinder is generally sufficient.

- Cut-Off Wheel (various sizes): Useful for fine tuning cuts and reaching tight spots.

- Body Saw or Reciprocating Saw: An alternative to the angle grinder, especially for thicker metal.

- Welder (MIG or TIG): Only if you plan on welding the over-fenders.

- Welding Helmet & Protective Gear: If welding, safety is paramount.

- Body Filler & Spreader: To smooth out imperfections and blend the over-fenders.

- Sandpaper (various grits): For prepping the surface for filler and paint. (80, 120, 180, 220, 320 grit recommended)

- Primer & Paint: To protect the metal and match the over-fenders to your car.

- Rivets or Self-Tapping Screws: For securing the over-fenders.

- Drill with various drill bits: For drilling pilot holes for rivets or screws.

- Rivet Gun or Screwdriver: Depending on your chosen fastening method.

- Body Hammer & Dolly Set (optional): For minor metal shaping.

- Rust Inhibitor: To prevent rust after cutting the quarter panel.

- Seam Sealer: To prevent water from getting between the over-fender and the quarter panel.

- Jack & Jack Stands: To safely lift the vehicle.

- Wheel Chocks: For added safety.

Approximate Repair Costs: This project can vary wildly in cost. A DIY approach with fiberglass over-fenders can range from $200-$500 (including materials like filler, paint, and fasteners). Professional installation, including welding and paint, could easily exceed $1000-$2000, depending on the shop and the complexity of the job.

Step-by-Step Installation

1. Preparation and Marking

Begin by safely lifting your 240SX using a jack and securely placing it on jack stands. Remove the rear wheels. Thoroughly clean the area around the rear quarter panel where the over-fenders will be installed. This will help ensure good adhesion of any filler or seam sealer you use later.

Carefully position the over-fender against the quarter panel and use a marking pen to trace the outline of where you need to cut. It's generally recommended to cut slightly inside the line, leaving a small lip. This allows for adjustments and prevents you from accidentally cutting too much. Consider the amount of tire clearance you need based on your wheel and tire setup.

Important Tip: Double-check your measurements and markings! "Measure twice, cut once" is a golden rule in bodywork.

2. Cutting the Quarter Panel

Put on your safety glasses, respirator, and gloves! Using your angle grinder, body saw, or reciprocating saw, carefully cut along the marked line. Take your time and make smooth, controlled cuts. Avoid applying too much pressure, as this can cause the cutting disc to bind or kick back.

Be mindful of any wiring or fuel lines located behind the quarter panel. It's a good idea to disconnect the battery before cutting to minimize the risk of electrical shorts.

After cutting, use a grinding wheel or file to smooth out any sharp edges. This will prevent cuts and make the area safer to work with.

Pro Tip: Use masking tape along the cut line to protect the surrounding paint from scratches.

3. Test Fitting and Adjustments

Now, test fit the over-fender again. Check for any areas where it doesn't sit flush against the quarter panel. Use a body hammer and dolly set to gently shape the metal if necessary. You may also need to trim the over-fender itself to achieve a perfect fit.

If you're planning on welding the over-fenders, now is the time to tack weld them into place. Make small, intermittent welds to avoid warping the metal. Once you're satisfied with the fit, you can fully weld the seams.

Caution: Welding requires experience and proper equipment. If you're not comfortable welding, consider using rivets or self-tapping screws.

4. Bodywork and Finishing

Once the over-fender is securely attached, it's time to blend it seamlessly into the existing bodywork. Apply body filler to any gaps or imperfections between the over-fender and the quarter panel. Use a spreader to create a smooth, even surface.

After the filler has dried, sand it down with progressively finer grits of sandpaper. Start with 80 grit to remove the bulk of the excess filler, then move to 120, 180, 220, and finally 320 grit to create a smooth, paint-ready surface.

Clean the area thoroughly with a tack cloth to remove any dust or debris. Apply a coat of primer to the entire area, and let it dry completely. Sand the primer lightly with 400 grit sandpaper to create a smooth surface for the paint.

Apply several coats of paint, following the manufacturer's instructions. Allow each coat to dry completely before applying the next. Once the paint is dry, you can apply a clear coat for added protection and shine.

Tip: Practice your painting technique on a scrap piece of metal before painting your car. This will help you achieve a professional-looking finish.

5. Final Assembly

Apply seam sealer to the inside of the over-fender where it meets the quarter panel. This will prevent water from getting between the two surfaces and causing rust.

Attach the over-fender using rivets or self-tapping screws. Drill pilot holes before inserting the fasteners to prevent cracking the over-fender. Use a rivet gun or screwdriver to secure the fasteners in place.

Apply rust inhibitor to any exposed metal on the inside of the quarter panel to prevent rust.

Reinstall the rear wheels and lower the car back to the ground.

Final Checks and Considerations

Once everything is assembled, double-check all fasteners to ensure they are tight. Inspect the over-fenders for any gaps or imperfections. Take the car for a test drive and listen for any unusual noises.

Wheel Alignment: Adding over-fenders and wider wheels can affect your car's wheel alignment. It's a good idea to have your alignment checked and adjusted after installing over-fenders.

Fender Liners: You may need to modify or remove the rear fender liners to accommodate the wider wheels. Consider aftermarket fender liners or trimming the existing ones.

Legal Considerations: Check your local laws regarding fender coverage and tire protrusion. Some jurisdictions have regulations regarding how far your tires can extend beyond the body of the car.

Installing rear over-fenders on your Nissan 240SX is a rewarding project that can significantly enhance its appearance and performance. By following these steps and taking your time, you can achieve a professional-looking result that you'll be proud of. Good luck, and happy motoring!