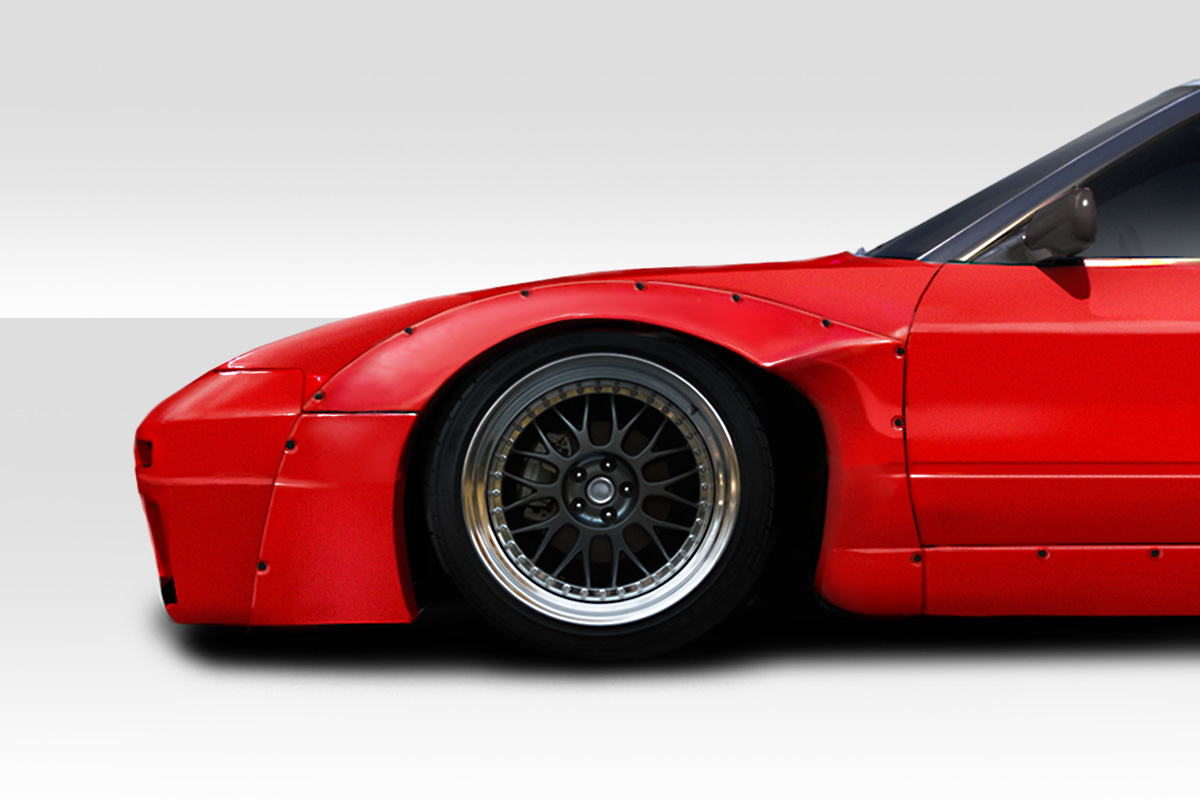

Installation Of Widebody Fender Kits On A Nissan 240sx

So, you're thinking about bolting on a widebody fender kit to your Nissan 240SX? Excellent choice! It's a fantastic way to drastically improve the stance, accommodate wider wheels, and generally give your S-chassis a more aggressive look. However, this isn't just a simple bolt-on affair. It requires patience, some fabrication skills, and a good understanding of the process. This article will walk you through the installation, assuming you have a reasonably well-equipped garage and some prior experience with bodywork.

Before You Begin: Preparation is Key

Before you even think about cracking open that widebody kit box, there are a few crucial steps you need to take. Proper preparation will save you headaches down the road.

1. Parts Inventory and Inspection

First and foremost, unpack everything! Take a detailed inventory of all the parts included in your kit. Compare it to the parts list provided by the manufacturer. Make sure nothing is missing. This is especially important if you purchased the kit second-hand. Also, carefully inspect each piece for any damage incurred during shipping. Pay close attention to cracks, chips, and warping. Contact the seller immediately if you find anything concerning.

2. Test Fitting (Absolutely Essential!)

This is arguably the most important step. Do not skip the test fit! Before you cut or drill anything, loosely attach each fender and side skirt to your 240SX using clamps or tape. Observe how the panels align with the existing body lines. Look for any major discrepancies or areas where the fitment is significantly off. This will give you a clear picture of what modifications will be necessary. Note any areas that need trimming, sanding, or even filling. Remember, no two cars are exactly alike, and even "perfect" kits often require some tweaking.

"Perfect fitment is a myth. Expect to do some work."

3. Tools and Materials

Gather your tools and materials beforehand. You'll need:

- Safety Glasses and Dust Mask: Absolutely essential for protecting yourself from dust and debris.

- Grinder with Cut-off Wheel: For cutting the existing fenders.

- Drill with Various Drill Bits: For drilling mounting holes.

- Riveter: For installing rivets (if your kit uses them).

- Clamps: For holding the widebody panels in place during fitting and installation.

- Sandpaper (Various Grits): For smoothing edges and preparing surfaces for paint.

- Body Filler (Bondo): For filling gaps and imperfections.

- Measuring Tape and Marking Tools: For accurate measurements and marking cutting lines.

- Primer and Paint: To match the widebody kit to your car's color (unless you're wrapping it).

- Socket Set and Wrenches: For removing and installing existing hardware.

- Jack and Jack Stands: To safely lift and support your car.

4. Protecting Your Car

Cover any areas of your car that you don't want to get scratched or dusty. Use masking tape and plastic sheeting to protect the surrounding paint. This is especially important around the areas you'll be cutting and grinding.

Installation Process: One Fender at a Time

Now that you're prepped, let's get to the actual installation. We'll tackle one fender at a time to keep things organized. Always work slowly and carefully. Rushing will only lead to mistakes.

1. Removing the Existing Fenders

Start by removing the stock fenders. This usually involves unbolting them from the inner fender well and the body of the car. Refer to your 240SX's service manual for specific instructions. Be careful not to damage any of the surrounding panels. Store the old fenders safely, as you might need them later.

2. Marking and Cutting

This is where things get a little nerve-wracking. You'll need to cut the existing fender arches to create clearance for the wider wheels. This is *critical* to avoid rubbing. Use your test fit as a guide. Mark the cutting line on the existing fender, leaving enough material to fold over and create a clean edge. I recommend starting with a smaller cut and gradually increasing it until you achieve the desired clearance. Using a cut-off wheel, carefully cut along the marked line. Work slowly and in stages to prevent overheating the metal.

3. Folding and Sealing the Cut Edge

Once you've made the cut, you'll want to fold over the sharp edge to prevent injury and corrosion. Use a hammer and dolly (or even just a pair of pliers) to carefully fold the metal inward. This will create a smooth, rounded edge. After folding, seal the exposed metal with primer and paint to prevent rust. You can also use seam sealer for added protection. This is important, especially in areas prone to moisture or road salt.

4. Attaching the Widebody Fender

Now it's time to attach the new widebody fender. Use clamps to hold it in place and ensure it's properly aligned with the body lines. This is where you'll start drilling mounting holes. Most widebody kits use rivets or screws to attach to the existing body. Mark the locations of the mounting holes on both the widebody fender and the car's body. Drill pilot holes, and then enlarge them to the correct size for your chosen fasteners. Attach the fender using rivets or screws. If using rivets, make sure you have a good quality riveter to ensure a secure and lasting connection. If using screws, consider using self-tapping screws for easier installation.

5. Addressing Gaps and Imperfections

Even with the best-fitting kits, you'll likely encounter some gaps or imperfections. This is where body filler (Bondo) comes in handy. Apply a thin layer of body filler to any gaps or uneven areas. Allow it to dry completely, and then sand it smooth using progressively finer grits of sandpaper. Repeat this process until you achieve a seamless transition between the widebody fender and the car's body. This is time consuming, but essential for a professional looking job. A "feathered" edge is key.

6. Repeating for the Other Fenders

Repeat steps 1-5 for the remaining fenders. Remember to take your time and work carefully. Consistent execution is key to a uniform and professional-looking result.

Final Touches: Paint and Finishing

Once all the fenders are installed and smoothed, it's time for paint. Prime the entire widebody kit and any areas where you've used body filler. This will provide a good surface for the paint to adhere to. Apply several coats of paint, following the manufacturer's instructions. Allow the paint to dry completely between coats. After the paint has dried, you can apply a clear coat for added protection and shine. Wet sanding with very fine grit sandpaper (2000 grit or higher) can help achieve an even smoother finish before clear coating. Polishing is the final touch, bringing out the full gloss of the paint.

Important Considerations:

- Wheel Fitment: Installing a widebody kit is often done to accommodate wider wheels. Measure carefully to determine the optimal wheel width and offset. Use an online wheel offset calculator to help you visualize the fitment.

- Suspension Setup: A wider track width can affect your car's handling. Consider adjusting your suspension setup to compensate. This might involve upgrading your coilovers, sway bars, or control arms.

- Professional Help: If you're not comfortable with any of these steps, don't hesitate to seek professional help. A qualified body shop can ensure a proper installation and a flawless finish. It's better to pay for quality work than to risk damaging your car or ending up with a subpar result.

Installing a widebody kit on your Nissan 240SX is a challenging but rewarding project. With careful planning, patience, and attention to detail, you can transform your S-chassis into a true head-turner. Good luck, and happy wrenching!