Jdm Turn Signal Lens Optical Properties And Visibility

JDM (Japanese Domestic Market) vehicles often boast unique styling and features, and their turn signals are no exception. While aesthetics play a role, the optical properties and visibility of JDM turn signal lenses are crucial for safety. This article explores these aspects, providing a comprehensive overview for anyone considering JDM turn signals or simply curious about their design.

Understanding the Importance of Turn Signal Visibility

Before diving into the specifics of JDM turn signal lenses, it's essential to understand why visibility is paramount. Turn signals serve as a vital communication tool between drivers, alerting others to your intention to turn or change lanes. Poor visibility can lead to misinterpretations, potentially causing accidents. Several factors contribute to turn signal visibility, including:

- Brightness: The intensity of the light emitted.

- Color: The specific wavelength of light (typically amber or yellow).

- Lens Design: How the lens focuses and disperses the light.

- Lens Condition: Clarity and absence of damage or fading.

Each of these elements plays a critical role in ensuring that your turn signals are easily seen and understood by other drivers, even in varying weather conditions and times of day.

Optical Properties of JDM Turn Signal Lenses

The optical properties of a turn signal lens dictate how it manipulates light. JDM lenses often employ specific designs to maximize light output and visibility. Here's a closer look at some key optical properties:

Lens Material

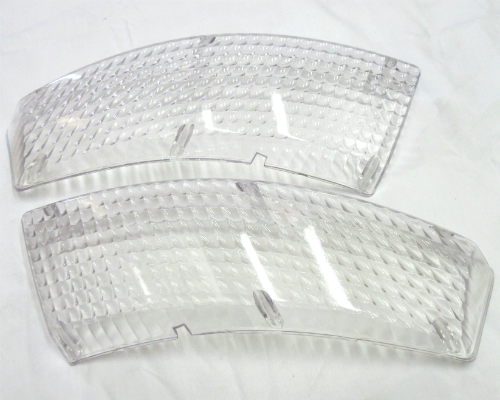

The material used to construct the lens significantly impacts its optical characteristics. Common materials include:

- Polycarbonate: Known for its high impact resistance and good light transmission. Polycarbonate lenses are durable and less prone to shattering, making them a safe choice.

- Acrylic: Offers excellent clarity and is more affordable than polycarbonate. However, acrylic is more susceptible to scratches and cracking.

- Glass: While less common in modern vehicles, glass lenses provide exceptional clarity and resistance to yellowing. However, they are heavier and more fragile.

The chosen material directly affects the lens's ability to transmit light efficiently and maintain its clarity over time. UV resistance is also crucial, as prolonged exposure to sunlight can cause lenses to yellow and become less transparent.

Lens Design and Refraction

The shape and surface features of a turn signal lens are carefully engineered to refract (bend) light in a specific pattern. This refraction helps to spread the light evenly and increase its apparent brightness. Common design features include:

- Fresnel Lenses: Characterized by concentric grooves that focus light into a narrow beam. This design is often used to project a bright, focused signal over a long distance.

- Diffusers: Lenses with a textured or frosted surface that scatters light in multiple directions. Diffusers provide wider coverage, making the signal visible from a broader angle.

- Reflectors: Internal surfaces that reflect light back towards the viewer, further enhancing brightness.

The specific combination of these features determines the overall light distribution pattern of the turn signal. JDM lenses often prioritize a balance between brightness and wide-angle visibility.

Color and Light Transmission

The color of the lens is critical for compliance with regulations and for ensuring clear communication. Amber or yellow is the universally accepted color for turn signals. The lens material is treated with dyes or coatings to achieve the desired color. However, not all colored lenses are created equal.

High-quality lenses use pigments that are resistant to fading and maintain their color integrity over time. They also allow a high percentage of the light emitted by the bulb to pass through, ensuring that the signal remains bright and easily visible. Inferior lenses may fade quickly or block too much light, reducing the effectiveness of the turn signal.

Factors Affecting Visibility of JDM Turn Signals

Even with well-designed lenses, several external factors can impact the visibility of JDM turn signals:

Bulb Type and Wattage

The type and wattage of the bulb used in the turn signal assembly directly affect the brightness of the light emitted. Using a bulb with too low a wattage will result in a dim signal, while using a bulb with too high a wattage can damage the lens or wiring. LED bulbs are becoming increasingly popular for turn signals due to their brightness, energy efficiency, and long lifespan. However, it's essential to ensure that LED bulbs are compatible with the vehicle's electrical system and that they provide the correct light output and beam pattern.

Lens Condition

Over time, turn signal lenses can become scratched, faded, or cracked due to exposure to the elements and road debris. These imperfections can significantly reduce the amount of light transmitted through the lens, making the signal less visible. Regularly cleaning and polishing the lenses can help to maintain their clarity. Severely damaged lenses should be replaced to ensure optimal visibility.

Weather Conditions

Visibility is particularly critical in adverse weather conditions such as rain, fog, and snow. In these conditions, the ambient light is reduced, and the contrast between the turn signal and the background is lessened. JDM lenses designed for harsh climates often incorporate features such as reflectors and diffusers to enhance visibility in challenging conditions. It's also important to ensure that the turn signals are properly aimed to maximize their effectiveness in wet or foggy weather.

Regulations and Compliance

It's crucial to understand the regulations regarding turn signal visibility in your region before installing JDM turn signals. Many countries have specific requirements for the color, brightness, and beam pattern of turn signals. Non-compliant turn signals can result in fines or even the failure of vehicle inspections.

It is important to research your local laws and regulations.

Before purchasing JDM turn signals, verify that they meet the required standards. Look for certifications such as DOT (Department of Transportation) or E-mark, which indicate that the lenses have been tested and approved for use in your region. Failing to comply with these regulations can lead to legal issues and compromise safety.

Maintaining Optimal Turn Signal Visibility

Ensuring the long-term visibility of your JDM turn signals requires regular maintenance and attention. Here are some tips:

- Regular Cleaning: Clean the lenses regularly with a mild soap and water solution to remove dirt, grime, and road debris.

- Polishing: Use a plastic polish specifically designed for automotive lenses to remove minor scratches and restore clarity.

- Bulb Replacement: Replace bulbs as soon as they burn out to maintain optimal brightness.

- Lens Inspection: Inspect the lenses regularly for cracks, fading, or other damage. Replace damaged lenses promptly.

- Wiring Check: Periodically check the wiring and connectors for corrosion or damage. Clean or replace damaged components as needed.

By following these simple maintenance tips, you can help to ensure that your JDM turn signals remain bright, clear, and visible for years to come.

Conclusion

The optical properties and visibility of JDM turn signal lenses are essential for safety and compliance. By understanding the materials, design features, and factors that affect visibility, you can make informed decisions about purchasing and maintaining JDM turn signals. Remember to prioritize safety by choosing high-quality lenses that meet regulatory standards and by performing regular maintenance to ensure optimal visibility in all driving conditions. Investing in good quality JDM lenses provides not only a unique look, but peace of mind that your intentions are being clearly communicated on the road.

Always prioritize safety above aesthetics when modifying your vehicle's safety features.