Keeping The Engine In Sync Understanding The Camshaft Oil Control Valve Bank 2

Maintaining optimal engine performance and fuel efficiency often hinges on the precise synchronization of internal components. One crucial element in achieving this synchronization, particularly in modern vehicles, is the Camshaft Oil Control Valve (OCV). When issues arise with this valve, specifically on Bank 2, it can lead to a cascade of problems. This article delves into the intricacies of the Camshaft OCV on Bank 2, equipping you with the knowledge to diagnose, maintain, and potentially resolve common issues.

Background: Variable Valve Timing (VVT) and the Camshaft OCV

To understand the role of the Camshaft OCV, we need to first grasp the concept of Variable Valve Timing (VVT). VVT is a technology used in many modern engines to optimize valve timing based on engine speed, load, and other factors. Traditional engines have fixed valve timing, meaning the intake and exhaust valves always open and close at the same points relative to the piston's movement. This is a compromise, as the optimal valve timing for low-speed cruising is different from that for high-speed acceleration.

VVT systems, however, allow the valve timing to be adjusted dynamically. This results in improved fuel efficiency, increased power output, and reduced emissions. There are several different VVT systems, but one of the most common uses a hydraulically controlled cam phaser. The cam phaser is a mechanism that can advance or retard the camshaft's position relative to the crankshaft. This changes when the valves open and close.

The Camshaft OCV is the electrical-hydraulic component that controls the flow of oil to the cam phaser. Think of it as a precisely controlled valve that directs oil pressure to either advance or retard the camshaft timing. The Engine Control Unit (ECU) monitors engine conditions and sends signals to the OCV to adjust the oil flow as needed.

The term "Bank 2" refers to one side of a V-shaped engine (V6 or V8). In a V-engine, the cylinders are arranged in two banks, usually at an angle to each other. Bank 1 is conventionally the bank that contains cylinder #1. Bank 2 is then the opposite bank. The specific cylinder numbering and bank identification can vary between manufacturers, so consulting your vehicle's service manual is crucial.

Technical Breakdown: How the Camshaft OCV Works

The Camshaft OCV is typically a solenoid-operated valve. Here's a step-by-step breakdown of its operation:

- ECU Signal: The ECU receives data from various sensors (e.g., crankshaft position sensor, camshaft position sensor, engine speed sensor, throttle position sensor) and determines the optimal valve timing. Based on this, it sends a Pulse Width Modulated (PWM) signal to the Camshaft OCV.

- Solenoid Activation: The PWM signal energizes the solenoid within the OCV. The PWM signal varies the amount of time the solenoid is energized, allowing for precise control of the valve's position.

- Valve Movement: The energized solenoid moves a spool valve within the OCV. This spool valve directs pressurized engine oil to different chambers within the cam phaser.

- Oil Flow to Cam Phaser: Depending on the position of the spool valve, oil is directed to either the advance or retard chamber of the cam phaser.

- Cam Phaser Adjustment: The pressurized oil in the advance or retard chamber causes the cam phaser to rotate the camshaft, changing the valve timing.

- Feedback Loop: The camshaft position sensor provides feedback to the ECU about the actual camshaft position. The ECU then adjusts the PWM signal to the OCV to fine-tune the valve timing.

The OCV relies on clean, pressurized oil to function correctly. Any contamination or insufficient oil pressure can impair its performance.

Common Issues and Maintenance Concerns

Several factors can lead to problems with the Camshaft OCV on Bank 2. Identifying the root cause is essential for effective repair.

- Dirty or Contaminated Oil: This is perhaps the most common culprit. Sludge and debris in the engine oil can clog the OCV, restricting oil flow and preventing it from functioning properly.

- Faulty Solenoid: The solenoid itself can fail, preventing the valve from opening and closing correctly. This can be due to electrical problems, mechanical wear, or corrosion.

- Worn or Damaged Spool Valve: The spool valve inside the OCV can become worn or damaged, leading to leaks and inaccurate oil flow control.

- Low Oil Pressure: Insufficient oil pressure can prevent the OCV from operating effectively. This could be due to a faulty oil pump, a clogged oil filter, or excessive engine wear.

- Electrical Issues: Problems with the wiring harness, connectors, or the ECU itself can prevent the OCV from receiving the correct signal.

- Cam Phaser Issues: Although not directly the OCV's fault, a failing or damaged cam phaser can cause the OCV to work harder and eventually fail.

Symptoms of a failing Camshaft OCV (Bank 2) can include:

- Check Engine Light: This is the most common symptom. Diagnostic Trouble Codes (DTCs) related to VVT or camshaft position are often stored, such as P0014, P0017, P0019, P0020, P0022. The specific codes will depend on the vehicle and the nature of the failure.

- Rough Idling: The engine may idle roughly or stall, especially when cold.

- Poor Fuel Economy: Inefficient valve timing can lead to reduced fuel efficiency.

- Loss of Power: The engine may feel sluggish or lack power, particularly during acceleration.

- Engine Noise: Unusual engine noises, such as ticking or rattling, can sometimes be associated with VVT problems.

Diagnostics and Troubleshooting

Proper diagnosis is critical. Here's a suggested approach:

- Read Diagnostic Trouble Codes (DTCs): Use an OBD-II scanner to retrieve any stored DTCs. Note the codes and research their meaning. Focus on codes related to VVT, camshaft position, or the Camshaft OCV itself.

- Inspect Wiring and Connectors: Carefully examine the wiring harness and connectors leading to the Bank 2 Camshaft OCV. Look for any signs of damage, corrosion, or loose connections.

- Test the OCV Solenoid: Use a multimeter to check the resistance of the OCV solenoid. Compare the reading to the manufacturer's specifications. An open circuit or short circuit indicates a faulty solenoid.

- Check Oil Pressure: Verify that the engine oil pressure is within the normal range. Use a mechanical oil pressure gauge or consult the vehicle's service manual for the correct specifications.

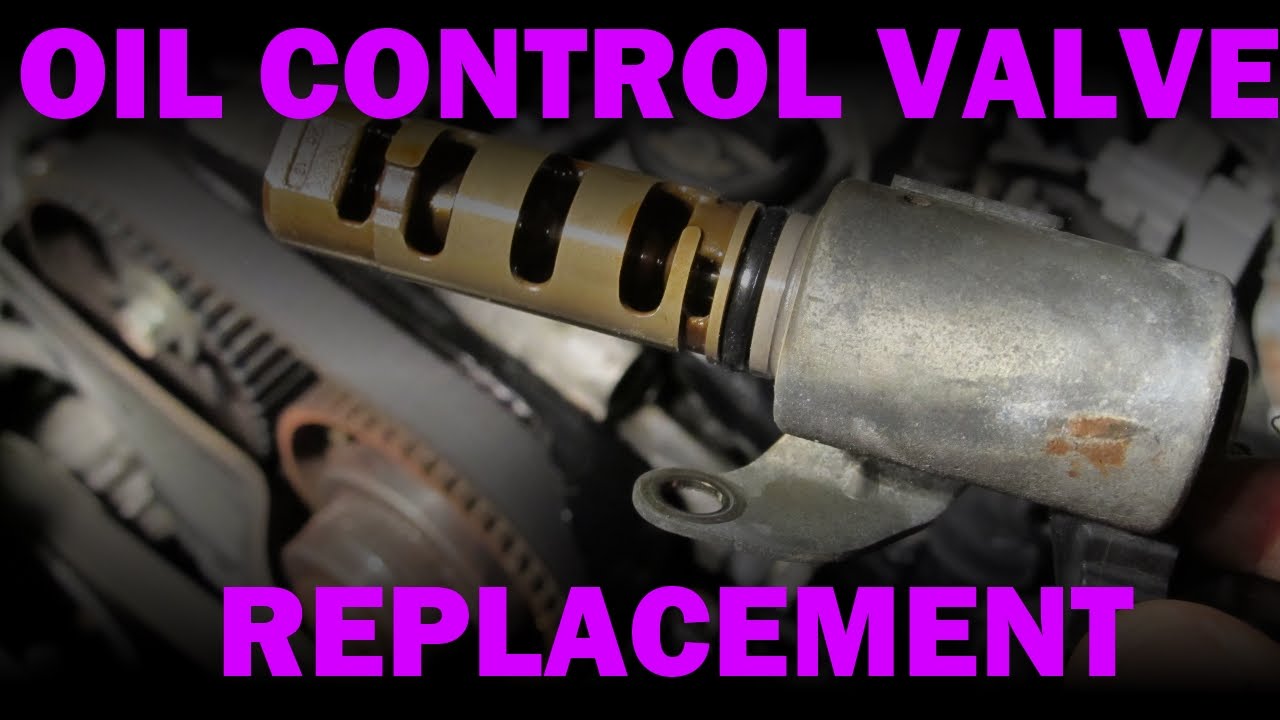

- Visually Inspect the OCV (if accessible): If possible, remove the OCV and visually inspect it for signs of contamination, damage, or wear. Look for sludge or debris clogging the valve.

- Perform an Actuator Test (if available): Some advanced scan tools have the ability to activate the Camshaft OCV directly. This allows you to observe its operation and listen for any unusual noises.

Do’s and Don’ts / Best Practices

Here are some important guidelines to follow when working with the Camshaft OCV:

- DO use the correct engine oil: Always use the grade and type of oil recommended by the vehicle manufacturer. Using the wrong oil can lead to VVT problems.

- DO change your oil regularly: Follow the manufacturer's recommended oil change intervals. Regular oil changes help prevent sludge buildup and contamination.

- DO use a high-quality oil filter: A good oil filter will help remove contaminants from the oil, protecting the OCV and other engine components.

- DO be careful when handling the OCV: The OCV is a delicate component. Avoid dropping it or subjecting it to excessive force.

- DO disconnect the battery before working on electrical components: This will prevent accidental shorts and protect the vehicle's electrical system.

- DON'T use excessive force when tightening the OCV mounting bolts: Overtightening can damage the valve or the engine block. Torque the bolts to the manufacturer's specifications.

- DON'T attempt to clean the OCV with harsh chemicals: Harsh chemicals can damage the OCV's internal components. If cleaning is necessary, use a mild solvent specifically designed for electrical components.

- DON'T ignore VVT-related DTCs: Address VVT problems promptly to prevent further damage to the engine.

Conclusion

The Camshaft OCV plays a critical role in optimizing engine performance and fuel efficiency through Variable Valve Timing. Understanding its function, common issues, and proper maintenance practices is essential for any experienced DIYer. If you're experiencing VVT-related symptoms or have a DTC related to the Camshaft OCV on Bank 2, follow the diagnostic steps outlined above to identify the root cause. If you're comfortable with basic mechanical and electrical repairs, you may be able to resolve the issue yourself. However, if you're unsure or lack the necessary tools or experience, it's always best to consult a qualified mechanic. Regular oil changes with the correct type of oil remain the most crucial preventative measure. By staying proactive and addressing potential problems early, you can keep your engine running smoothly and efficiently for years to come.