Ls Swap Engine Mount Fabrication And Vibration Dampening

The LS engine swap has become a mainstay in the automotive world, offering a relatively affordable and powerful upgrade to a wide variety of vehicles. However, successfully mating an LS engine to a chassis it wasn't originally designed for requires careful planning and execution, especially when it comes to engine mount fabrication and vibration dampening. This article explores the key considerations for a smooth and reliable LS swap, focusing on custom engine mount creation and effective vibration management.

Why Custom Engine Mounts are Often Necessary for LS Swaps

While some companies offer pre-fabricated LS swap kits for specific vehicles, many projects require custom engine mounts. The reasons for this vary:

- Unique Chassis: Your vehicle might be an older model, a modified platform, or simply one for which no pre-made swap kits exist.

- Custom Modifications: You might have altered the firewall, transmission tunnel, or other areas, affecting engine placement.

- Desired Engine Position: Fine-tuning engine location can optimize weight distribution, driveline angles, and exhaust routing.

Fabricating your own engine mounts allows for precise engine positioning, ensuring proper clearances and optimal performance. This is critical for longevity and prevents stress on other components. Skipping this step can lead to headaches down the road.

The Engine Mount Fabrication Process: A Step-by-Step Guide

Creating sturdy and well-designed engine mounts involves several stages. Safety is paramount. Always wear appropriate protective gear, including eye protection and gloves, when welding or working with metal.

1. Planning and Measurement

This is arguably the most critical step. Accurate measurements are essential. Consider the following:

- Engine Placement: Determine the precise location of the engine within the engine bay. Factors include oil pan clearance, header fitment, transmission tunnel space, driveshaft alignment, and accessory drive clearance.

- Driveline Angles: Aim for optimal driveline angles to minimize vibration and wear on the transmission and rear end. Incorrect driveline angles are a major cause of vibrations after an LS swap.

- Mounting Points: Identify suitable locations on the engine block and chassis for attaching the mounts. Look for strong, reinforced areas.

- Component Clearance: Ensure adequate clearance around all engine components, including the headers, oil pan, steering components, and any wiring or hoses.

Use cardboard templates or simple mock-up mounts to visualize the engine position and potential interference issues. Document all measurements carefully.

2. Material Selection

The materials you choose for your engine mounts are crucial for strength and durability. Common choices include:

- Steel: Mild steel is the most common and affordable option. It's easy to weld and provides excellent strength.

- Chromoly: Stronger and lighter than mild steel, chromoly is a good choice for performance applications. However, it requires specialized welding techniques.

- Aluminum: While lighter than steel, aluminum is generally not recommended for engine mounts due to its lower strength and potential for fatigue.

Choose a steel thickness appropriate for the engine's weight and horsepower. A minimum of 1/4 inch steel plate is typically recommended for most LS swaps. Always over-engineer when in doubt.

3. Fabrication and Welding

Once you have your measurements and materials, begin fabricating the mounts. This typically involves cutting, shaping, and welding steel plates and tubing.

- Cut the Steel: Use a plasma cutter, cutting torch, or angle grinder to cut the steel plates to the desired shapes and sizes.

- Shape the Metal: Use a hammer, vise, or hydraulic press to bend and shape the steel as needed.

- Weld the Components: Use a MIG or TIG welder to join the steel components together. Ensure proper penetration and weld quality for a strong and durable mount.

If you are not experienced in welding, it is highly recommended to have a professional welder fabricate your engine mounts. Poor welding can lead to mount failure and potentially catastrophic engine damage.

4. Test Fitting and Adjustment

After fabrication, test fit the engine mounts in the vehicle. Check for proper clearances and alignment. Make any necessary adjustments before final welding.

It's much easier to make adjustments to tack-welded mounts than fully welded ones. This iterative process ensures a perfect fit.

5. Final Welding and Finishing

Once you are satisfied with the fit, complete the final welding. Grind down any rough edges and apply a coat of paint or powder coating to protect the metal from rust and corrosion. Powder coating is highly recommended for long term durability. Don't skimp on rust protection!

Vibration Dampening: Essential for a Comfortable and Reliable Swap

LS engines, like any internal combustion engine, generate significant vibrations. Properly dampening these vibrations is crucial for a comfortable and reliable driving experience. Excessive vibration can lead to:

- Increased Noise: Annoying buzzing and rattling noises within the cabin.

- Component Failure: Premature wear and tear on engine components, drivetrain components, and chassis components.

- Reduced Drivability: A harsh and uncomfortable driving experience.

There are several ways to effectively dampen engine vibrations:

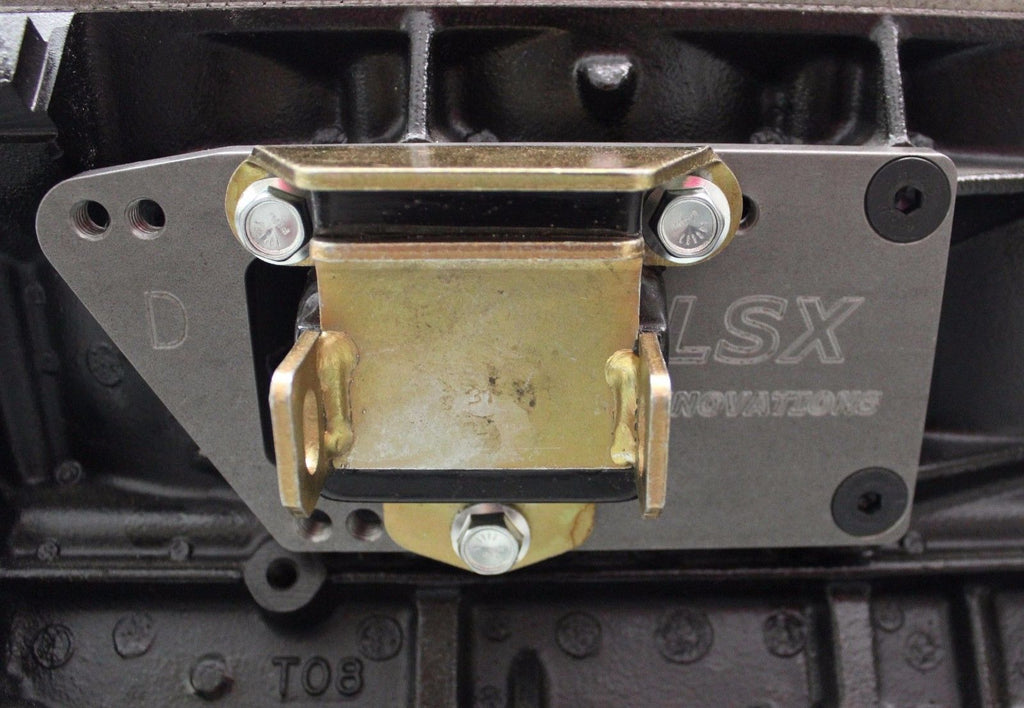

1. Engine Mount Bushings

The most common method of vibration dampening is through the use of rubber or polyurethane bushings in the engine mounts. These bushings act as isolators, absorbing vibrations before they can be transmitted to the chassis.

- Rubber Bushings: Offer the best vibration dampening but are less durable than polyurethane bushings.

- Polyurethane Bushings: More durable than rubber bushings but transmit more vibration. Choose a durometer (hardness) appropriate for your application. Softer bushings offer better isolation but may allow for more engine movement.

Consider your driving style and intended use of the vehicle when selecting bushings. Street-driven cars typically benefit from softer bushings, while track cars may require stiffer bushings for improved engine control.

2. Harmonic Balancer

The harmonic balancer is a crucial component that dampens torsional vibrations within the crankshaft. Using a quality harmonic balancer designed for your specific LS engine is essential for preventing engine damage.

3. Transmission Mount

A properly selected transmission mount also contributes to vibration dampening. Similar to engine mounts, transmission mounts typically use rubber or polyurethane bushings to isolate vibrations. Choose a mount that is compatible with your transmission and chassis.

4. Exhaust System Isolation

The exhaust system can be a significant source of vibration and noise. Use flexible exhaust hangers and avoid rigid connections to the chassis. Ensure adequate clearance between the exhaust system and any body panels.

5. Sound Deadening Materials

Applying sound deadening materials to the interior of the vehicle can help to further reduce noise and vibration. These materials can be installed on the floor, firewall, and roof of the vehicle.

Troubleshooting Vibration Issues After an LS Swap

Even with careful planning and execution, vibration issues can sometimes arise after an LS swap. Here are some common causes and solutions:

- Incorrect Driveline Angles: Measure and correct driveline angles using shims or adjustable components.

- Loose Engine Mounts: Check and tighten all engine mount bolts.

- Damaged Engine Mount Bushings: Inspect and replace damaged or worn engine mount bushings.

- Exhaust System Contact: Ensure adequate clearance between the exhaust system and the chassis.

- Harmonic Balancer Issues: Inspect the harmonic balancer for damage or wear. Replace if necessary.

- Torque Converter Issues: If you are using an automatic transmission, a faulty torque converter can cause vibrations.

Diagnosing vibration issues can be challenging, but a systematic approach can help pinpoint the source of the problem.

Conclusion

Successfully performing an LS swap involves more than just dropping an engine into a new chassis. Careful planning, precise engine mount fabrication, and effective vibration dampening are crucial for a reliable and enjoyable driving experience. By following the steps outlined in this article, you can increase your chances of a successful LS swap and avoid common pitfalls. Remember to prioritize safety and seek professional help if needed. Good luck with your project!