Nissan Altima Caliper Bracket Bolt Torque

The seemingly simple act of tightening a bolt often belies a wealth of engineering considerations. This is particularly true when dealing with critical components in automotive braking systems, such as the caliper bracket bolts. These bolts, responsible for securing the brake caliper bracket to the vehicle's knuckle or spindle, play a vital role in ensuring proper braking performance and, ultimately, safety. Ignoring the specified torque value for these bolts on a Nissan Altima (or any vehicle) can lead to catastrophic consequences. This article will delve into the intricacies of caliper bracket bolt torque, specifically focusing on the Nissan Altima, exploring why the correct torque is crucial and the technical factors that influence it.

Why Torque Matters: A Deep Dive

Torque, simply put, is a twisting force. When tightening a bolt, you're applying torque that creates tension within the bolt itself. This tension, often referred to as preload, is what actually holds the clamped parts (in this case, the caliper bracket and the knuckle) together. Think of it like a stretched rubber band: the tighter you stretch it, the greater the force it exerts to return to its original state.

Applying the correct torque to the caliper bracket bolts achieves several critical objectives:

- Ensuring Adequate Clamping Force: The primary function is to provide sufficient clamping force to securely hold the caliper bracket in place. Insufficient torque means insufficient clamping force, potentially leading to bracket movement, vibration, and ultimately, brake failure. A loose bracket can also contribute to uneven brake pad wear and noise.

- Preventing Bolt Loosening: Vibration is a constant companion in a vehicle's braking system. Proper preload helps the bolt resist loosening under these vibrations. If the preload is too low, the bolt can gradually unwind, leading to a dangerous loss of clamping force.

- Avoiding Bolt Failure: Conversely, over-torquing can be just as detrimental. Exceeding the specified torque can stretch the bolt beyond its elastic limit, causing it to yield (permanently deform). This weakening of the bolt makes it susceptible to fracture under stress. In extreme cases, the bolt can even snap during the tightening process.

- Maintaining Caliper Alignment: The caliper needs to be precisely aligned with the brake rotor for even pad wear and optimal braking performance. Correctly torqued caliper bracket bolts contribute to maintaining this alignment. A misaligned caliper can cause premature pad wear, rotor damage, and reduced braking efficiency.

Nissan Altima Specifics: Factors Influencing Torque Values

The specified torque value for the caliper bracket bolts on a Nissan Altima is not arbitrary. It's a carefully calculated figure based on several factors, including:

Bolt Size and Grade

The diameter and grade of the bolt are paramount. Larger diameter bolts, naturally, can withstand higher torque values. The bolt grade indicates the bolt's material strength – higher grade bolts are made from stronger materials and can handle more tension. Nissan engineers select specific bolts with precisely defined dimensions and material properties to meet the braking system's demands. Using an aftermarket bolt of unknown or incorrect grade is strongly discouraged and can compromise safety.

Thread Pitch

Thread pitch, the distance between threads, also influences the torque value. Finer threads generally require lower torque values compared to coarser threads for achieving the same clamping force. This is because finer threads provide more surface area for friction, translating to a higher clamping force for a given torque.

Material of the Mating Components

The material of the caliper bracket and the knuckle or spindle to which it attaches plays a role. The torque value is chosen to ensure that the clamping force doesn't exceed the yield strength of either component. Using excessively high torque could damage the threads in the knuckle or deform the caliper bracket.

Lubrication (or Lack Thereof)

The presence or absence of lubrication on the bolt threads significantly affects the torque-tension relationship. Lubrication reduces friction, allowing a greater proportion of the applied torque to be converted into bolt tension. Therefore, if the service manual specifies a dry torque value (no lubricant), applying lubricant can lead to over-torquing and potential bolt damage. Conversely, if the manual specifies lubrication, failing to lubricate the threads will result in insufficient clamping force, even if the specified torque is achieved.

Type of Caliper

While less influential than the factors above, the specific type of caliper used on the Altima (e.g., sliding caliper versus fixed caliper) can have a minor impact on the recommended torque value. Sliding calipers, for instance, often have a different bracket design than fixed calipers, which may necessitate slightly different torque specifications.

Finding the Correct Torque Specification

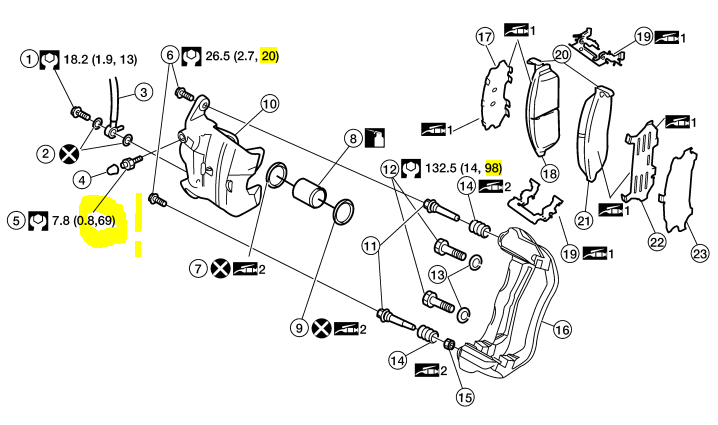

The most reliable source for the correct caliper bracket bolt torque specification is the Nissan Altima's factory service manual. These manuals contain detailed information about all aspects of vehicle maintenance and repair, including torque specifications for every bolt and fastener. Reputable aftermarket repair databases, such as AllData or Mitchell OnDemand, also provide access to this information.

Never rely on generic torque charts or online forums for torque values related to safety-critical components like brake caliper brackets. These sources may contain inaccurate or incomplete information. The consequences of using the wrong torque value can be severe.

Tools and Techniques for Accurate Torque Application

Achieving the correct torque requires the right tools and techniques:

- Torque Wrench: A torque wrench is an indispensable tool for accurately tightening bolts to a specified torque value. There are several types of torque wrenches available, including click-type, beam-type, and digital torque wrenches. Click-type wrenches are the most common and provide an audible "click" when the desired torque is reached. Digital torque wrenches offer even greater accuracy and often feature digital displays for precise torque readings.

- Socket: Use the correct size and type of socket for the caliper bracket bolts. A socket that is too loose can slip and round off the bolt head, making it impossible to tighten or loosen.

- Cleanliness: Ensure that the bolt threads and the threads in the knuckle are clean and free from debris. Dirty threads can interfere with the tightening process and lead to inaccurate torque readings.

- Proper Technique: When using a click-type torque wrench, apply steady and even pressure until the wrench clicks. Avoid jerking or pulling on the wrench, as this can result in an inaccurate torque reading. If the service manual indicates a specific tightening sequence, follow it precisely.

- Re-Torquing: Some service manuals recommend re-torquing the caliper bracket bolts after a specified period of time or mileage. This helps to ensure that the bolts remain properly tightened and that the clamping force is maintained.

Consequences of Incorrect Torque

The consequences of using incorrect torque on caliper bracket bolts can range from minor annoyances to catastrophic brake failure. Here's a more detailed look:

Under-Torquing

- Brake Noise: A loose caliper bracket can vibrate and rattle, creating annoying brake noise.

- Uneven Pad Wear: A misaligned caliper due to a loose bracket can cause uneven brake pad wear, requiring more frequent pad replacements.

- Reduced Braking Performance: A loose caliper can compromise braking performance, increasing stopping distances.

- Potential for Bracket Failure: Constant vibration of a loose bracket can lead to metal fatigue and eventual bracket failure.

- Complete Brake Failure: In the worst-case scenario, a loose caliper can detach from the knuckle, resulting in complete brake failure.

Over-Torquing

- Bolt Damage: Over-torquing can stretch the bolt beyond its elastic limit, weakening it and making it susceptible to fracture.

- Thread Damage: Excessive torque can damage the threads in the knuckle or caliper bracket, requiring expensive repairs.

- Distortion of Components: Over-torquing can distort the caliper bracket or knuckle, affecting brake alignment and performance.

- Bolt Failure During Tightening: The most immediate consequence of over-torquing is snapping the bolt during the tightening process, requiring extraction of the broken bolt and replacement.

Conclusion

The seemingly simple task of tightening caliper bracket bolts is, in fact, a critical operation that requires careful attention to detail. Understanding the underlying principles of torque, considering the specific factors that influence torque values, and using the correct tools and techniques are essential for ensuring safe and reliable braking performance. Always consult the Nissan Altima's factory service manual for the correct torque specification and follow all recommended procedures. Remember, proper brake maintenance is paramount to your safety and the safety of others on the road. Ignoring these details can have serious, even life-threatening, consequences. A little extra care and attention to detail can make all the difference.