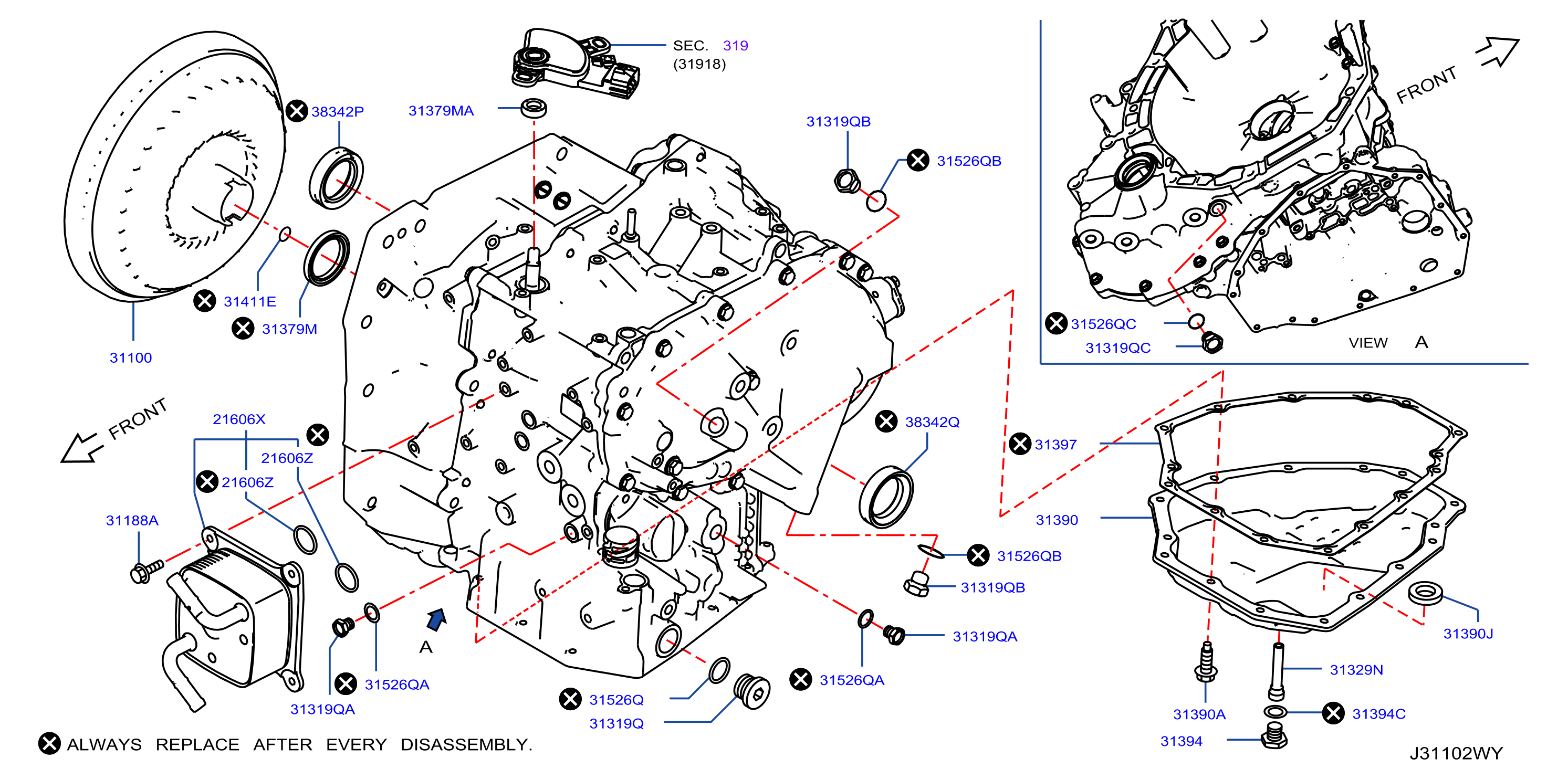

Nissan Cvt Transmission Pan Bolt Torque

The Continuously Variable Transmission (CVT) has become a staple in many modern vehicles, offering enhanced fuel efficiency and a smooth driving experience. Nissan, in particular, has extensively utilized CVTs across its model range. While seemingly simple in operation, the long-term reliability of a CVT hinges on proper maintenance, and a crucial aspect of that maintenance revolves around correctly torquing the transmission pan bolts. This guide delves into the reasons why achieving the correct torque is paramount, the potential consequences of improper torque, and provides a step-by-step overview of the procedure.

Understanding the Importance of Torque

Torque, in the context of fasteners, refers to the rotational force applied when tightening a bolt or nut. It's not simply about making the fastener "tight"; it's about applying the precise amount of clamping force to create a secure and leak-proof seal. When dealing with a CVT transmission pan, the pan bolts serve a critical function: they clamp the transmission pan against the transmission case, creating a fluid-tight seal that prevents transmission fluid from leaking. Insufficient or excessive torque can lead to serious problems. Let's explore these issues in detail:

Insufficient Torque: The Leaky Nightmare

Under-torquing pan bolts is arguably the more common error, and its consequences can be readily apparent. When the bolts are not tightened to the specified torque value, the clamping force is insufficient. This allows the transmission pan gasket to compress unevenly or not compress at all in certain areas. The result is a compromised seal, leading to transmission fluid leaks. Even small leaks can escalate quickly, causing:

- Low Transmission Fluid Level: Transmission fluid is the lifeblood of a CVT. It lubricates internal components, cools the transmission, and provides the hydraulic pressure necessary for proper operation. Low fluid levels starve the transmission, leading to increased friction, overheating, and ultimately, premature failure.

- Erratic Shifting and Performance Issues: The CVT relies on precise hydraulic pressure to adjust the transmission ratio. Low fluid levels can cause pressure fluctuations, resulting in jerky shifting, delayed engagement, and a general loss of performance.

- Potential for Catastrophic Failure: Prolonged operation with low transmission fluid can lead to irreversible damage to the CVT's internal components, requiring costly repairs or even a complete transmission replacement.

Excessive Torque: The Thread-Stripping Peril

While seemingly less problematic than under-torquing, over-torquing pan bolts presents its own set of dangers. Applying too much torque can stretch or even break the bolts themselves. More commonly, it can strip the threads in the transmission case, which is usually made of aluminum, a relatively soft metal. The repercussions of stripped threads can be significant:

- Weakened Fasteners: Over-tightened bolts are stressed beyond their designed limits. This weakens the metal, making them prone to fatigue and eventual failure.

- Stripped Threads: Once the threads in the transmission case are stripped, the bolt will no longer hold properly. This can create a leak, similar to under-torquing, and makes it impossible to achieve a reliable seal.

- Costly Repairs: Repairing stripped threads in a transmission case can be a complex and expensive process. Options include using thread repair inserts (like Heli-Coil), tapping the hole to a larger size, or, in severe cases, replacing the entire transmission case.

The Right Torque: Finding the Specification

The correct torque specification for the Nissan CVT transmission pan bolts is crucial. Do not assume a generic torque value. The torque specification can vary depending on the specific CVT model and the year of the vehicle. Therefore, you must consult the following resources:

- Vehicle's Repair Manual: This is the primary source of information. A factory service manual or a reputable aftermarket repair manual (like Haynes or Chilton) will provide the accurate torque specification for your specific vehicle.

- Online Databases: Some online automotive databases provide torque specifications. However, verify the information against other sources to ensure accuracy.

- Nissan Dealership: Contact your local Nissan dealership's service department. They can provide the correct torque specification based on your vehicle's VIN.

Typically, the torque values for Nissan CVT transmission pan bolts fall within the range of 7-10 Nm (Newton-meters) or 62-88 in-lbs (inch-pounds). Again, verify the exact specification for your vehicle.

Step-by-Step Guide to Torquing the Transmission Pan Bolts

This guide assumes you have already drained the transmission fluid and replaced the filter and gasket (if applicable). Ensure you have the correct tools and equipment before proceeding:

- Torque Wrench: A properly calibrated torque wrench is essential. Use a wrench that is appropriate for the torque range. A beam-type, click-type, or digital torque wrench will work, but ensure it's accurate.

- Socket Set: You'll need the correct size socket for the transmission pan bolts.

- New Transmission Pan Gasket (if applicable): Always replace the gasket if it's old or damaged. Use the correct type of gasket for your CVT model.

- Clean Rags: For wiping up any spills or debris.

- Safety Glasses and Gloves: To protect your eyes and hands.

Procedure:

- Clean the Mating Surfaces: Ensure the transmission pan and the transmission case mating surfaces are clean and free of any old gasket material or debris. Use a scraper and a solvent to remove any residue. Be careful not to damage the aluminum surfaces.

- Install the Gasket: Install the new transmission pan gasket (if applicable) onto the transmission pan. Some gaskets have specific orientations, so refer to the manufacturer's instructions.

- Position the Pan: Carefully align the transmission pan with the transmission case and ensure the bolts align with the holes.

- Hand-Tighten the Bolts: Install all the transmission pan bolts by hand, tightening them snugly but not excessively. This ensures that the pan is evenly seated against the transmission case.

- Tighten in a Star Pattern: This is crucial for even clamping force. Tighten the bolts in a star pattern, alternating between bolts on opposite sides of the pan. This prevents warping and ensures even compression of the gasket.

- First Pass: Half Torque: Set your torque wrench to approximately half of the specified torque value. Using the star pattern, tighten all the bolts to this lower torque value.

- Second Pass: Final Torque: Set your torque wrench to the specified torque value. Again, using the star pattern, tighten all the bolts to the final torque value. Listen for the click of the torque wrench (if using a click-type) or observe the reading on the dial or display (if using a beam-type or digital wrench).

- Verify: After torquing all the bolts, visually inspect the pan and gasket to ensure that they are properly seated and that there are no gaps.

- Refill Transmission Fluid: Add the correct type and amount of transmission fluid as specified in your vehicle's repair manual.

- Check for Leaks: After refilling the fluid, start the engine and let it run for a few minutes. Check for any leaks around the transmission pan. If you see any leaks, stop the engine and re-torque the bolts. If the leak persists, you may need to remove the pan and inspect the gasket for damage.

Important Considerations

- Calibration: Ensure your torque wrench is properly calibrated. A poorly calibrated wrench can lead to inaccurate torque readings and the problems described earlier. Have your torque wrench calibrated periodically by a qualified technician.

- Bolt Condition: Inspect the transmission pan bolts for any signs of damage, such as stripped threads or corrosion. Replace any damaged bolts.

- Thread Engagement: Ensure that the bolts have sufficient thread engagement in the transmission case. If the threads are too short, they may not provide adequate clamping force.

- Aluminum Cases: Be especially careful when torquing bolts into aluminum cases. Aluminum is a soft metal and is easily stripped.

By following these guidelines, you can ensure that your Nissan CVT transmission pan bolts are properly torqued, contributing to the long-term reliability and performance of your vehicle's transmission.