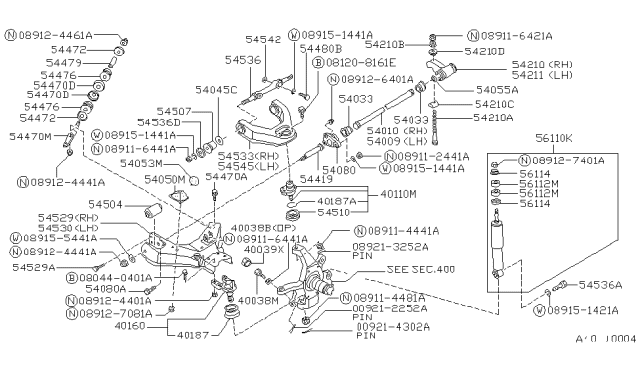

Nissan Hardbody Front Suspension Diagram

Alright, let's dive into the front suspension system of the Nissan Hardbody. This is a robust but relatively straightforward setup, and understanding its components and how they work together is crucial for maintenance, troubleshooting, and even potential modifications. We'll break down a typical Hardbody front suspension – typically a 2WD model, as 4WD systems use a different setup – focusing on the core elements and their functions.

The Basic Components: A Deconstructed View

The Nissan Hardbody's front suspension primarily utilizes a double-wishbone configuration. This design offers a good balance of handling, ride quality, and load-carrying capacity, making it well-suited for a light-duty pickup truck. Here's a breakdown of the key components:

Upper and Lower Control Arms

These are the heart of the suspension. Think of them as the 'A' arms that connect the wheel hub assembly to the vehicle's frame.

- Upper Control Arm: Typically shorter than the lower arm. It's responsible for controlling the camber angle of the wheel as the suspension moves through its travel. It pivots on two bushings attached to the frame and connects to the spindle (or steering knuckle) with a ball joint.

- Lower Control Arm: Larger and more robust than the upper arm. It primarily absorbs the bulk of the impact from road imperfections and supports the vehicle's weight. It also pivots on two bushings attached to the frame, and connects to the spindle with a ball joint. Due to its primary role in weight support and impact absorption, the lower control arm bushings are often a point of wear and tear.

Spindle (Steering Knuckle)

The spindle, also known as the steering knuckle, is the component that actually holds the wheel bearing and wheel hub assembly. It pivots on the ball joints of the upper and lower control arms, allowing for steering. The brake caliper mounting points are also integrated into the spindle's design. It's a heavy-duty casting, crucial for the structural integrity of the suspension and steering system.

Coil Spring and Shock Absorber

These work in tandem to provide both suspension and damping:

- Coil Spring: The coil spring is what actually provides the suspension – the ability to absorb bumps and maintain ride height. It's a helical spring that compresses and expands in response to road irregularities. The spring rate – measured in pounds per inch (lbs/in) – determines how stiff or soft the suspension is. A higher spring rate means a stiffer ride.

- Shock Absorber (Damper): The shock absorber, often shortened to just "shock," controls the rate at which the coil spring compresses and rebounds. Without shocks, the suspension would oscillate uncontrollably after hitting a bump, leading to a bouncy and unstable ride. Shocks use hydraulic fluid and a piston to dampen these oscillations. There are different types of shocks, including gas-charged and hydraulic, each with its own characteristics.

In the Hardbody, the coil spring typically sits between the lower control arm and a pocket in the frame. The shock absorber is mounted within the coil spring, creating a compact and integrated unit.

Torsion Bar (Not in all models, but important to mention)

While less common in 2WD models, some Hardbodies, particularly those geared towards heavier-duty applications, utilize torsion bars as their primary spring mechanism. A torsion bar is a long, steel bar that twists to absorb energy. One end is anchored to the vehicle's frame, and the other end is connected to the lower control arm. As the suspension moves, the torsion bar twists, providing resistance and acting as the spring. Torsion bars offer adjustable ride height, but can be more complex to adjust properly. If present, adjusting the torsion bar adjusting bolts will raise or lower the ride height.

Ball Joints

Ball joints are essentially pivots that allow the control arms to move up and down while also allowing the spindle to turn for steering. They connect the control arms to the spindle. They're a critical wear item, as they are constantly under stress. There are two ball joints per side: an upper ball joint and a lower ball joint. Inspecting these regularly is essential for safety.

Bushings

Bushings are rubber or polyurethane insulators that isolate vibrations and noise. They're found at the pivot points of the control arms, where they attach to the frame. Bushings allow for controlled movement while minimizing the transmission of road noise and vibrations into the cabin. Like ball joints, bushings wear out over time, leading to sloppy handling and increased noise. Polyurethane bushings offer increased durability and stiffness compared to rubber, but can also transmit more vibration.

Sway Bar (Stabilizer Bar)

The sway bar, also called a stabilizer bar, is a transverse bar that connects the left and right sides of the suspension. Its purpose is to reduce body roll during cornering. When the vehicle leans to one side, the sway bar twists, transferring some of the load to the opposite wheel, helping to keep the vehicle more level. Sway bar end links connect the sway bar to the control arms (or sometimes the struts on other vehicles).

How It All Works Together: The Suspension Cycle

When the wheel encounters a bump, the following sequence occurs:

- The tire impacts the obstacle, and the force is transmitted to the spindle.

- The spindle moves upwards, causing the control arms to pivot on their bushings.

- The coil spring (or torsion bar) compresses, absorbing the energy of the impact.

- The shock absorber dampens the oscillations of the spring, preventing the suspension from bouncing uncontrollably.

- The sway bar (if equipped) resists body roll by transferring some of the load to the opposite wheel.

As the wheel travels over the bump and returns to its normal position, the process reverses. The coil spring expands, pushing the wheel back down, and the shock absorber continues to control the motion.

Common Problems and Troubleshooting

The Hardbody's front suspension is generally reliable, but like any mechanical system, it's susceptible to wear and tear. Here are some common problems:

- Worn Ball Joints: Symptoms include clunking noises over bumps, loose steering, and uneven tire wear. To check for ball joint play, jack up the vehicle and use a pry bar to check for movement in the ball joint.

- Worn Bushings: Symptoms include sloppy handling, clunking noises, and vibrations. Visually inspect the bushings for cracks, tears, or excessive play.

- Leaking Shock Absorbers: Symptoms include a bouncy ride, poor handling, and visible oil leaks on the shock body.

- Sagging Coil Springs: This results in a lower ride height and reduced load-carrying capacity. Visually compare the ride height to factory specifications.

- Bent Control Arms: This is usually the result of a significant impact and can cause alignment issues and uneven tire wear.

Modifications and Upgrades

The Hardbody's front suspension can be modified to improve handling, ride quality, or off-road performance. Common modifications include:

- Lift Kits: These kits raise the ride height, providing more ground clearance for off-road use. They typically consist of longer coil springs, spacers, and extended shocks.

- Lowering Kits: These kits lower the ride height, improving handling and aesthetics. They typically consist of shorter coil springs and sometimes modified shocks.

- Performance Shocks: Upgrading to high-performance shocks can improve handling and ride quality. Options include adjustable shocks that allow you to fine-tune the damping characteristics.

- Polyurethane Bushings: Replacing the stock rubber bushings with polyurethane bushings can improve handling by reducing suspension flex. However, be aware that polyurethane bushings can transmit more vibration.

- Sway Bar Upgrades: Installing a thicker sway bar can further reduce body roll during cornering.

- Spindle Lift: This involves replacing the factory spindles with new spindles that have been designed to lift the truck. It maintains factory suspension geometry better than some other lift methods.

Important Considerations

When working on your Hardbody's front suspension, it's crucial to prioritize safety.

Always use jack stands to support the vehicle. Never rely solely on a jack.

Also, be aware that the coil springs are under significant tension. Use a spring compressor tool to safely remove and install the springs. Failure to do so can result in serious injury.

Finally, after any suspension work, it's essential to have the vehicle's wheel alignment checked and adjusted. This will ensure proper handling, prevent uneven tire wear, and maintain optimal fuel efficiency.

Understanding the Nissan Hardbody's front suspension system empowers you to perform basic maintenance, troubleshoot problems, and even explore performance upgrades. With the right tools and knowledge, you can keep your Hardbody riding smoothly and handling predictably for years to come.