Nissan Rogue Brake Caliper Torque Specs

The brake caliper, a seemingly simple component, plays a critical role in the safety and performance of any vehicle. It's responsible for squeezing the brake pads against the rotors, generating the friction necessary to slow down or stop the car. Ensuring the caliper is properly installed and, critically, torqued to the manufacturer's specifications is paramount. This isn't just about tightening a bolt; it's about ensuring the integrity of the braking system and the safety of yourself and others on the road.

Understanding Torque and Why It Matters

Before diving into the specific torque specs for a Nissan Rogue's brake calipers, it's crucial to understand what torque is and why it's so vital. Torque is a twisting force that tends to cause rotation. In the context of fasteners, it's the measure of how tightly a bolt or nut is tightened. It's expressed in units of pound-feet (lb-ft) or Newton-meters (Nm). Applying the correct torque is absolutely critical. Too little torque and the fastener may loosen over time, leading to catastrophic failure. Too much torque and you risk damaging the threads, stretching the bolt beyond its yield point, or even breaking the bolt outright. In the case of brake calipers, improper torque can lead to:

- Brake failure: Loose calipers can cause uneven brake pad wear, reduced braking effectiveness, and ultimately, complete brake failure.

- Damage to components: Overtightening can damage the caliper mounting bracket, the caliper itself, or the bolts, necessitating expensive repairs.

- Premature wear: Incorrect torque can lead to vibration and movement within the braking system, accelerating wear and tear on all components.

Think of it like this: Each bolt is designed to clamp the components together with a specific force. That force is achieved by stretching the bolt a specific amount as it's tightened. Applying the correct torque ensures that the bolt is stretched to that optimal point, creating the necessary clamping force without exceeding its structural limits. This is why a torque wrench is not just a tool; it's a precision instrument that's essential for any brake job.

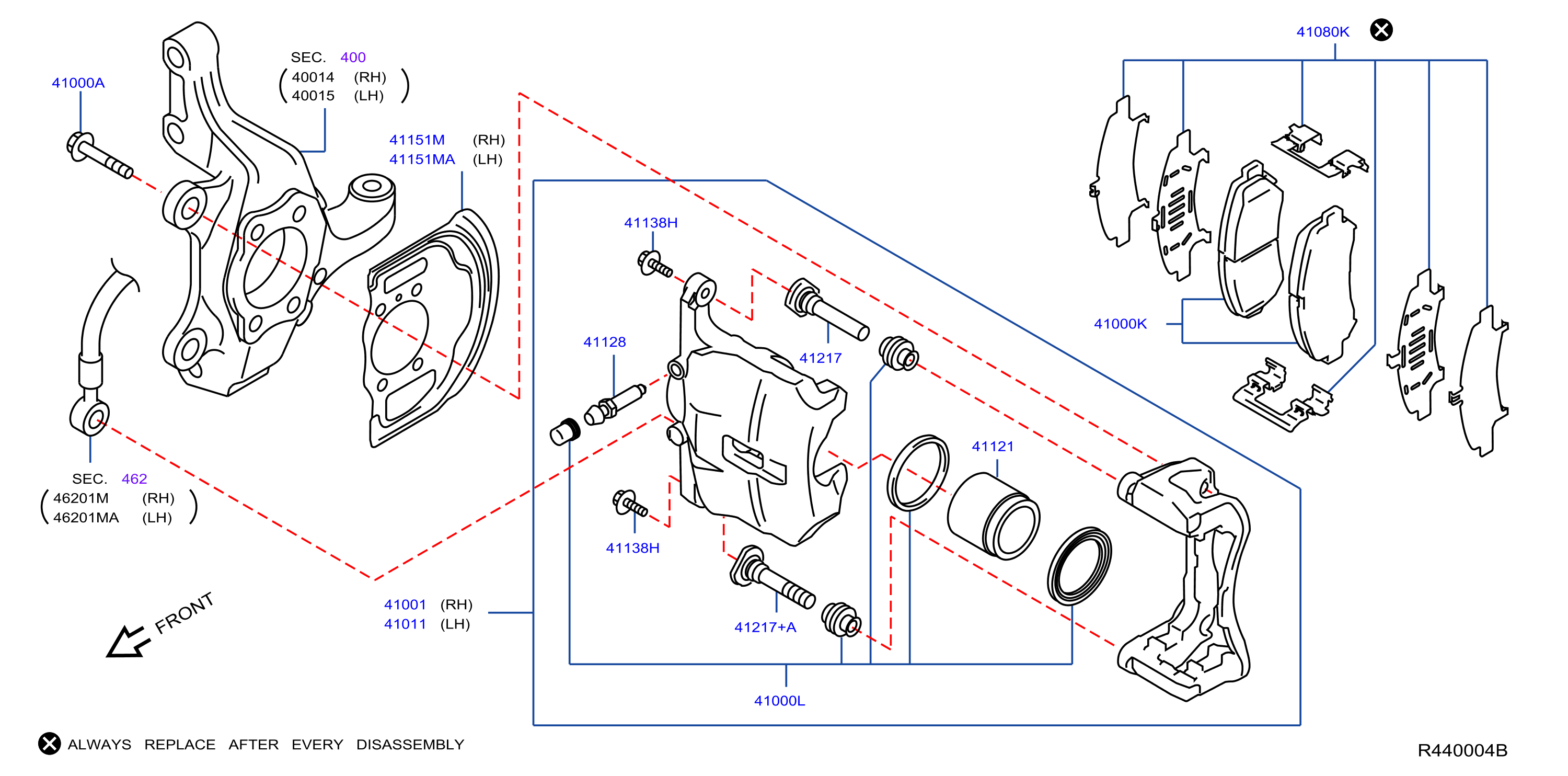

Nissan Rogue Brake Caliper Torque Specifications

Now, let's get down to the specifics. The torque specifications for a Nissan Rogue's brake calipers can vary slightly depending on the model year and whether you're working on the front or rear brakes. Always consult your vehicle's repair manual or a reputable online database for the precise specifications for your specific Rogue model year. However, as a general guideline, here are typical torque values:

Front Brake Caliper Bracket Bolts:

These bolts secure the caliper mounting bracket to the wheel hub. They are typically larger and require a higher torque value. A common range is 83 - 98 lb-ft (113 - 133 Nm). Again, verify this specification for your exact model year.

Front Brake Caliper Guide Pin Bolts:

These smaller bolts secure the caliper itself to the mounting bracket, allowing it to slide and apply even pressure to the brake pads. These typically require significantly less torque, usually in the range of 25 - 30 lb-ft (34 - 41 Nm). Exceeding this torque can easily damage the guide pins or the caliper itself.

Rear Brake Caliper Bracket Bolts:

Similar to the front, these bolts secure the rear caliper mounting bracket to the axle. The torque specification is generally in the same range as the front bracket bolts: 83 - 98 lb-ft (113 - 133 Nm). Once more, verify the value for your specific model year.

Rear Brake Caliper Guide Pin Bolts:

These bolts secure the rear caliper to the mounting bracket. The torque requirement is typically similar to the front caliper guide pin bolts: 25 - 30 lb-ft (34 - 41 Nm). Accuracy is crucial here to prevent damage.

Important Considerations:

- Thread Condition: Always inspect the threads of the bolts and the mounting holes for damage or corrosion. Clean the threads thoroughly with a wire brush. If the threads are damaged, replace the bolt or, if the damage is in the mounting hole, consider using a thread repair kit (e.g., a Heli-Coil).

- Lubrication: In some cases, the repair manual may specify whether the bolts should be lubricated before installation. If lubrication is required, use a light coating of anti-seize compound or the specified lubricant. Do not lubricate dry torque bolts unless the manual explicitly instructs you to do so. Lubricating dry torque bolts will significantly increase the clamping force and can easily lead to overtightening and damage.

- Torque Sequence: When tightening multiple bolts, it's often recommended to tighten them in a specific sequence. This helps to ensure even clamping pressure. The manual will usually specify a star pattern (criss-cross) or a spiral pattern.

- New Bolts: Some manufacturers recommend replacing the caliper bracket bolts with new bolts each time the brakes are serviced, especially if they are torque-to-yield (TTY) bolts. TTY bolts are designed to stretch a specific amount when tightened, and they should not be reused. Consult your vehicle's repair manual to determine if this applies to your Rogue.

Tools and Materials

To properly torque your Nissan Rogue's brake calipers, you'll need the following tools and materials:

- Torque Wrench: A quality torque wrench is absolutely essential. Choose a wrench that's appropriately sized for the torque range you'll be working with. Digital torque wrenches offer greater accuracy and ease of use, but beam-type torque wrenches are also a reliable option. Make sure it is calibrated regularly.

- Socket Set: You'll need a socket set with the correct sizes for the caliper bracket bolts and guide pin bolts.

- Wrench Set: A set of wrenches might be necessary for holding the guide pins while tightening the bolts.

- Brake Cleaner: To clean the brake components and remove any dirt, grease, or debris.

- Wire Brush: For cleaning the bolt threads.

- Anti-Seize Compound (if required): For lubricating the bolt threads.

- Gloves: To protect your hands from brake dust and chemicals.

- Safety Glasses: To protect your eyes from brake dust and debris.

- Vehicle Repair Manual: Absolutely essential for verifying torque specifications and procedures for your specific vehicle.

Step-by-Step Procedure

While a detailed brake replacement procedure is beyond the scope of this article, here's a general overview of the steps involved in torquing the brake caliper bolts:

- Prepare the Vehicle: Safely lift the vehicle and support it on jack stands. Ensure the parking brake is engaged (or wheels are chocked if working on the rear).

- Remove the Wheel: Remove the wheel to access the brake caliper.

- Remove the Old Caliper: If you're replacing the brakes, remove the old caliper. Refer to a separate guide or your vehicle's repair manual for the correct procedure.

- Install the New Caliper (or Reinstall the Old One): Position the caliper onto the mounting bracket.

- Install the Caliper Guide Pin Bolts: Thread the guide pin bolts into the caliper and tighten them to the specified torque. Use a torque wrench to ensure accuracy.

- Install the Caliper Bracket Bolts: If you removed the caliper bracket, reinstall it and tighten the bolts to the specified torque. Use a torque wrench and follow the recommended torque sequence, if any.

- Reinstall the Wheel: Reinstall the wheel and tighten the lug nuts to the specified torque.

- Test the Brakes: After completing the work on all brakes, carefully test the brakes before driving the vehicle. Pump the brake pedal several times to ensure proper engagement.

Final Thoughts

Properly torquing the brake caliper bolts on your Nissan Rogue is a critical step in ensuring the safety and performance of your vehicle. By understanding the importance of torque, using the correct tools, and following the manufacturer's specifications, you can confidently perform this task and keep your brakes in top condition. Remember, when in doubt, always consult a qualified mechanic. Safety should always be your top priority.