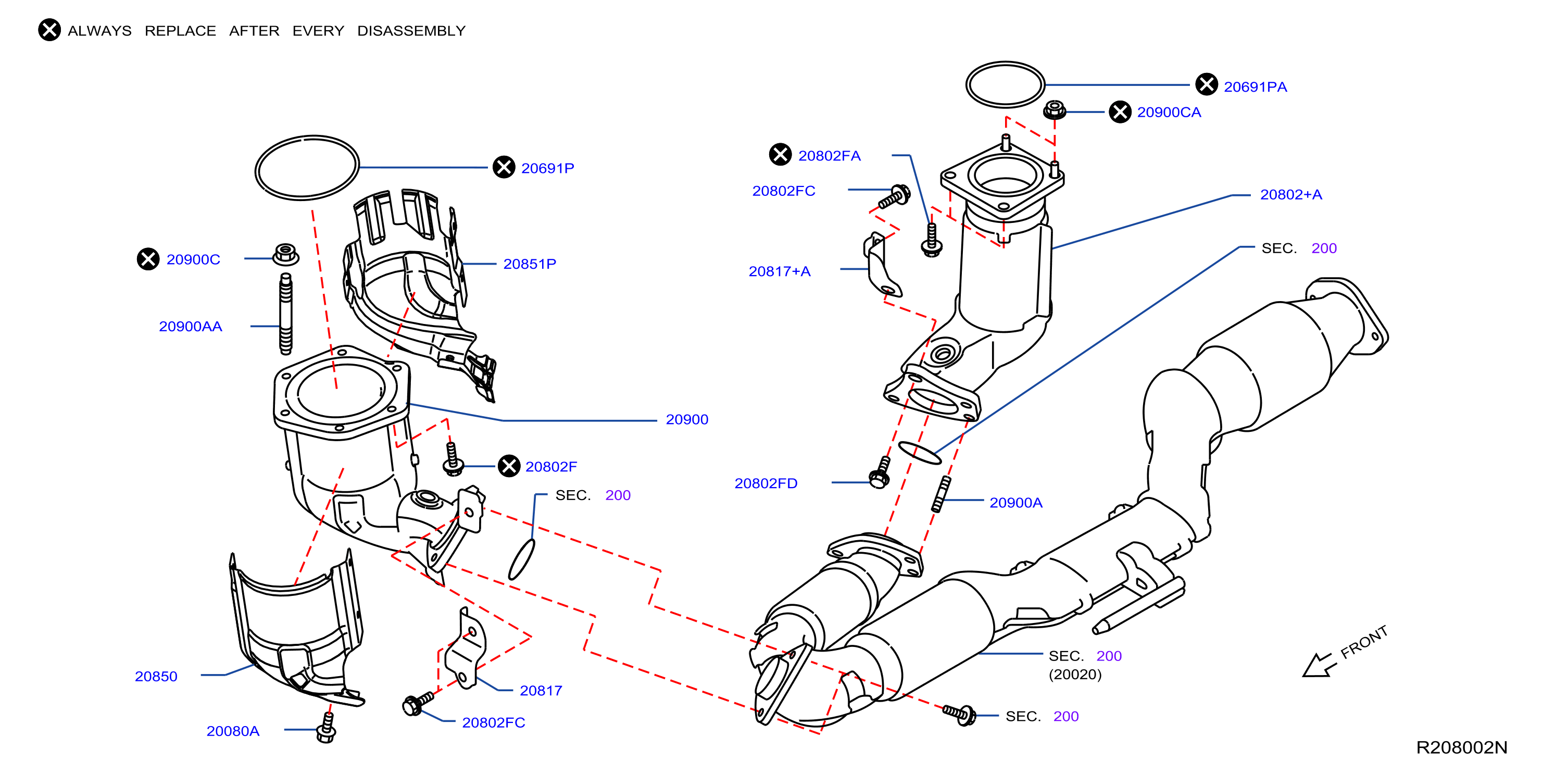

Nissan Titan 2006 Catalytic Converter

The 2006 Nissan Titan, a full-size pickup truck known for its robust performance and capability, relies on a sophisticated exhaust system to meet emissions standards. A critical component of this system is the catalytic converter. Understanding how this seemingly simple device functions is essential for appreciating the engineering behind modern vehicles and maintaining their performance and environmental compliance. This guide will delve into the technical intricacies of the 2006 Nissan Titan's catalytic converter.

What is a Catalytic Converter?

At its core, a catalytic converter is a device used to reduce the toxicity of pollutants in exhaust gases. It achieves this by facilitating chemical reactions that transform harmful substances like hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx) into less harmful substances: carbon dioxide (CO2), water (H2O), and nitrogen (N2). The name "catalytic converter" stems from the fact that these reactions occur with the help of catalysts, substances that accelerate chemical reactions without being consumed themselves.

Two-Way vs. Three-Way Converters

Older catalytic converters were primarily "two-way" converters, focusing on oxidizing HC and CO. However, modern vehicles like the 2006 Nissan Titan employ "three-way" converters, which address NOx emissions as well. This means the converter simultaneously handles three critical reactions:

Oxidation of Hydrocarbons (HC): HC + O2 → CO2 + H2O

Oxidation of Carbon Monoxide (CO): CO + O2 → CO2

Reduction of Nitrogen Oxides (NOx): NOx → N2 + O2

Construction and Materials

The 2006 Nissan Titan's catalytic converter is typically housed in a stainless steel casing for durability and resistance to corrosion from the high temperatures and corrosive gases present in the exhaust stream. Inside this casing lies the heart of the converter: the substrate. The substrate is a ceramic honeycomb structure coated with a thin layer of catalyst materials.

The Substrate

The honeycomb structure of the substrate serves a crucial purpose: it provides a large surface area for the exhaust gases to interact with the catalyst. Imagine trying to react gas over a flat surface versus passing it through a complex maze – the latter significantly increases the likelihood of reaction. The substrate is usually made of materials like cordierite (magnesium iron aluminum silicate), known for its heat resistance and low thermal expansion.

The Catalyst Coating

The real magic happens within the catalyst coating. This coating is a porous layer containing precious metals, primarily platinum (Pt), palladium (Pd), and rhodium (Rh). Each metal plays a specific role in the three-way conversion process.

- Platinum (Pt) and Palladium (Pd): These metals primarily act as oxidation catalysts, promoting the oxidation of HC and CO.

- Rhodium (Rh): Rhodium is primarily used as a reduction catalyst, aiding in the reduction of NOx into nitrogen and oxygen.

The precious metals are dispersed in a highly porous washcoat, typically composed of alumina (aluminum oxide – Al2O3). This washcoat further increases the surface area for the chemical reactions and helps in the dispersion of the precious metals.

Operating Principles

For the catalytic converter to function effectively, it needs to reach a certain operating temperature, typically around 400-800°C (750-1470°F). This "light-off temperature" is the point at which the catalysts become sufficiently active to initiate the desired chemical reactions. Before reaching this temperature, the converter's efficiency is significantly reduced, contributing to higher emissions during engine startup.

Once at operating temperature, the exhaust gases flow through the honeycomb structure of the substrate, coming into contact with the catalyst-coated surfaces. The precious metals catalyze the oxidation and reduction reactions, converting harmful pollutants into less harmful substances. The resulting exhaust gases, now containing primarily CO2, H2O, and N2, are then expelled from the exhaust system.

The Role of Oxygen Sensors

The catalytic converter's efficiency is heavily influenced by the air-fuel ratio (AFR) in the engine. The ideal AFR, known as the stoichiometric ratio, is approximately 14.7:1 (air to fuel). At this ratio, the three-way converter can operate most effectively, simultaneously reducing HC, CO, and NOx emissions. To maintain this optimal AFR, the 2006 Nissan Titan relies on oxygen sensors.

Typically, there are two oxygen sensors: one upstream (before) the catalytic converter and one downstream (after) the catalytic converter. The upstream sensor measures the oxygen content in the exhaust gases before they enter the converter, providing feedback to the engine control unit (ECU). The ECU then adjusts the fuel injection to maintain the stoichiometric AFR.

The downstream oxygen sensor monitors the oxygen content in the exhaust gases after they have passed through the converter. This sensor's readings provide information about the converter's efficiency. If the downstream sensor readings are significantly different from the upstream sensor readings, it indicates that the converter is functioning properly. However, if the downstream sensor readings are similar to the upstream sensor readings, it suggests that the converter is no longer effectively converting pollutants, potentially indicating a failure.

Potential Problems and Troubleshooting

Despite their robust construction, catalytic converters can fail over time due to several factors:

- Contamination: The catalyst materials can be poisoned by contaminants such as lead, sulfur, and phosphorus, which can be found in some fuels and engine oil. Even small amounts of these substances can significantly reduce the converter's efficiency.

- Overheating: Excessively rich air-fuel mixtures can lead to unburned fuel entering the converter. This fuel can then ignite within the converter, causing it to overheat and melt the substrate.

- Physical Damage: Impact from road debris or engine misfires can physically damage the converter, cracking the substrate or dislodging the catalyst coating.

- Age and Wear: Over time, the catalyst materials can degrade due to the high temperatures and constant exposure to exhaust gases.

Common symptoms of a failing catalytic converter include:

- Check Engine Light: The ECU may trigger the check engine light with codes related to catalytic converter efficiency (e.g., P0420 - Catalyst System Efficiency Below Threshold).

- Reduced Engine Performance: A clogged or failing converter can restrict exhaust flow, leading to reduced engine power and fuel economy.

- Increased Emissions: The vehicle may fail an emissions test due to elevated levels of HC, CO, and NOx.

- Rattling Noise: A damaged substrate can rattle inside the converter housing.

- Overheating Underneath Vehicle: Due to restriction of exhaust flow, excessive heat can build up under the vehicle.

Troubleshooting a potential catalytic converter issue typically involves:

- Scanning for Diagnostic Trouble Codes (DTCs): Using an OBD-II scanner to retrieve any stored DTCs related to the exhaust system.

- Inspecting the Converter for Physical Damage: Visually inspecting the converter for cracks, dents, or other signs of damage.

- Testing Oxygen Sensor Readings: Monitoring the readings from the upstream and downstream oxygen sensors to assess the converter's efficiency. A multimeter or scan tool can be used for this purpose.

- Performing a Backpressure Test: Measuring the exhaust backpressure to check for restrictions caused by a clogged converter.

Conclusion

The catalytic converter in the 2006 Nissan Titan is a vital component for reducing harmful emissions and meeting environmental regulations. By understanding its construction, operating principles, and potential failure modes, owners and enthusiasts can better maintain their vehicles and ensure they continue to operate efficiently and responsibly. While seemingly simple, the catalytic converter embodies sophisticated engineering principles and plays a crucial role in mitigating the environmental impact of internal combustion engines. Regular maintenance and prompt attention to any warning signs can help prolong the life of the converter and ensure optimal performance for years to come. Ignoring a failing catalytic converter can not only lead to increased emissions and reduced performance but can also potentially damage other engine components.