Nissan Xterra Crankshaft Position Sensor

The Nissan Xterra, particularly models from the early 2000s, is known for its rugged reliability, but like any vehicle, it has its share of common issues. One frequent culprit behind a no-start condition or erratic engine performance is a faulty Crankshaft Position Sensor (CKP). This article dives deep into the CKP sensor on the Xterra, covering its function, diagnosis, replacement, and potential performance implications. Consider this your comprehensive guide, written for the experienced DIYer.

Understanding the Crankshaft Position Sensor

Before we delve into the specifics of the Xterra, let's define what a CKP sensor actually does. The Crankshaft Position Sensor is a critical component of your engine's electronic control system. Its primary job is to monitor the position and rotational speed of the crankshaft. This information is then relayed to the Engine Control Unit (ECU), sometimes also called the Powertrain Control Module (PCM), which uses it to precisely time fuel injection and ignition.

Think of it this way: the ECU is the brain, and the CKP sensor is one of its key sensory inputs for understanding the engine's current state. Without accurate crankshaft position data, the ECU can't properly coordinate the firing of the spark plugs or the opening and closing of the fuel injectors. This leads to a multitude of problems, ranging from rough idling to a complete inability to start the engine.

There are generally two main types of CKP sensors:

- Hall Effect Sensors: These sensors use a magnetic field and a semiconductor to detect changes in position. They typically require a small amount of voltage to operate and produce a digital signal.

- Variable Reluctance (VR) Sensors: These sensors generate a voltage signal based on the changing magnetic field caused by the passing of teeth on a reluctor wheel attached to the crankshaft. They don't require an external voltage source.

The Nissan Xterra (depending on the year and engine) typically uses a Variable Reluctance (VR) sensor.

Symptoms of a Failing CKP Sensor on the Nissan Xterra

Recognizing the symptoms of a failing CKP sensor can save you time and money on unnecessary repairs. Here are the most common signs to watch out for in your Xterra:

- No-Start Condition: This is often the most dramatic symptom. If the CKP sensor completely fails, the ECU won't receive any crankshaft position data, preventing fuel injection and ignition. The engine will crank, but it won't fire.

- Rough Idling: If the sensor is sending inaccurate or intermittent signals, the engine may idle roughly or stall unexpectedly.

- Engine Stalling: The engine might stall while driving, especially at low speeds or when coming to a stop.

- Check Engine Light (CEL): A failing CKP sensor will almost always trigger the Check Engine Light. The diagnostic trouble codes (DTCs) associated with the CKP sensor typically include:

- P0335: Crankshaft Position Sensor "A" Circuit Malfunction

- P0336: Crankshaft Position Sensor "A" Circuit Range/Performance

- P0337: Crankshaft Position Sensor "A" Circuit Low Input

- P0338: Crankshaft Position Sensor "A" Circuit High Input

- P0339: Crankshaft Position Sensor "A" Circuit Intermittent

- Decreased Fuel Economy: Inaccurate timing can lead to inefficient combustion, resulting in a drop in fuel mileage.

- Hesitation or Stumbling During Acceleration: The engine may hesitate or stumble when you try to accelerate.

- Difficulty Starting When Hot: Some CKP sensors fail more readily when they get hot. This can lead to starting problems after the engine has been running for a while.

Diagnosing a CKP Sensor Issue

Before immediately replacing the CKP sensor, it's crucial to perform some basic diagnostic checks to confirm that it's indeed the source of the problem. Here's a step-by-step approach:

- Read the Diagnostic Trouble Codes (DTCs): Use an OBD-II scanner to retrieve any stored DTCs. A P0335, P0336, P0337, P0338, or P0339 code strongly suggests a CKP sensor issue. However, it's important to note that other problems can sometimes trigger similar codes, so further investigation is needed.

- Visual Inspection: Carefully inspect the CKP sensor and its wiring harness. Look for any signs of damage, such as frayed wires, cracked connectors, or oil contamination.

- Check the Wiring: Use a multimeter to check the continuity of the wiring between the CKP sensor and the ECU. Also, check for any shorts to ground. Refer to your Xterra's wiring diagram for the correct pin assignments.

- Test the Sensor's Resistance: Disconnect the CKP sensor and use a multimeter to measure its resistance. Compare the reading to the specifications in your Xterra's repair manual. A reading outside the specified range indicates a faulty sensor.

- Check the Sensor's Signal with an Oscilloscope: Ideally, use an oscilloscope to visualize the CKP sensor's signal while the engine is cranking. A healthy sensor will produce a clear, consistent waveform. A distorted or missing waveform suggests a problem with the sensor itself. This is the most accurate test, but it requires specialized equipment.

Important Note: A faulty crankshaft or camshaft position sensor can sometimes generate very similar symptoms and error codes. Be thorough in your testing to avoid replacing the wrong part.

Replacing the Crankshaft Position Sensor on a Nissan Xterra

If your diagnostics point to a faulty CKP sensor, replacing it is a straightforward DIY project, provided you have the necessary tools and a basic understanding of automotive repair. Always disconnect the negative battery cable before working on any electrical components.

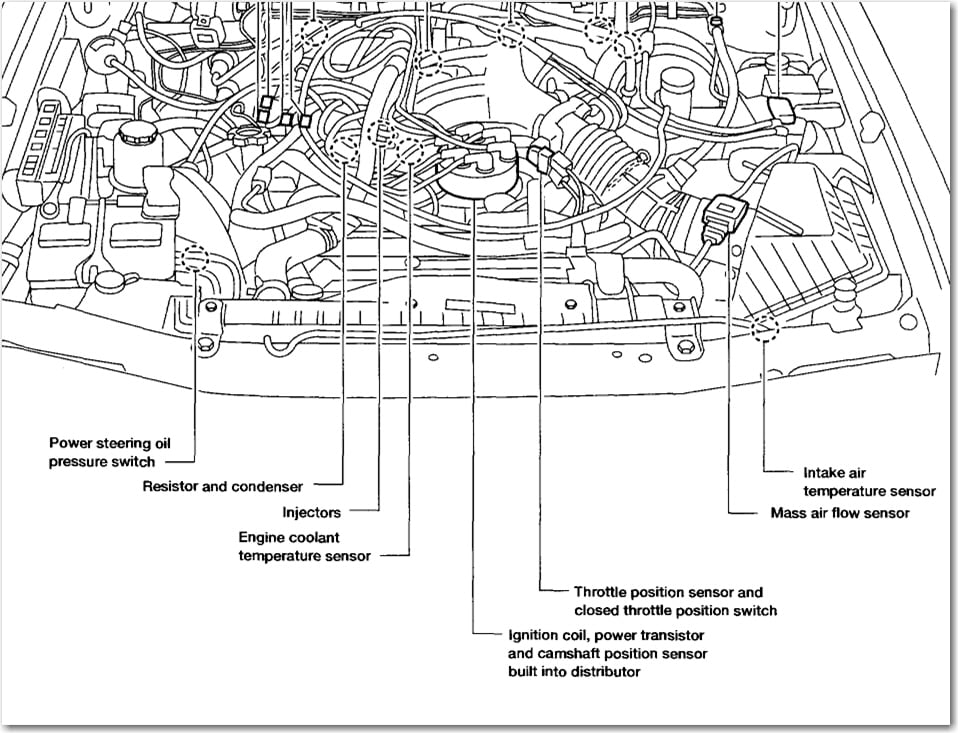

- Locate the CKP Sensor: The location of the CKP sensor varies slightly depending on the year and engine of your Xterra. Generally, it's located near the crankshaft pulley, either on the front or side of the engine block. Consult your repair manual for the exact location.

- Disconnect the Wiring Harness: Carefully disconnect the electrical connector from the CKP sensor. Be gentle to avoid damaging the connector.

- Remove the Old Sensor: Use the appropriate wrench or socket to remove the bolt that secures the CKP sensor in place. Carefully pull the sensor out of its mounting hole.

- Install the New Sensor: Install the new CKP sensor into the mounting hole. Make sure it's properly seated. Tighten the retaining bolt to the torque specification listed in your repair manual. Over-tightening can damage the sensor.

- Reconnect the Wiring Harness: Reconnect the electrical connector to the CKP sensor.

- Reconnect the Battery: Reconnect the negative battery cable.

- Clear Diagnostic Trouble Codes (DTCs): Use an OBD-II scanner to clear any stored DTCs.

- Start the Engine and Test: Start the engine and verify that it runs smoothly. Monitor the engine for any signs of hesitation, stalling, or rough idling.

Important Considerations:

- Quality of Replacement Sensor: Use a high-quality replacement CKP sensor from a reputable brand. Cheap aftermarket sensors are often unreliable and may fail prematurely.

- Proper Installation: Ensure the sensor is properly installed and torqued to the correct specification. Improper installation can lead to inaccurate readings and engine performance problems.

- Resetting the ECU: Some Xterra models may require a PCM (ECU) reset after replacing the CKP sensor. This allows the ECU to learn the new sensor's characteristics. Consult your repair manual for specific instructions on how to perform an ECU reset.

Performance Implications (Advanced)

While replacing a faulty CKP sensor primarily aims to restore normal engine operation, some enthusiasts explore the potential for performance gains. This is a more advanced topic and requires careful consideration.

Aftermarket CKP Sensors: Some aftermarket manufacturers offer CKP sensors with potentially different characteristics, such as improved signal clarity or faster response times. However, it's important to note that simply installing a "performance" CKP sensor is unlikely to yield significant power gains on a stock engine. These sensors are usually designed to be paired with other performance modifications, such as upgraded camshafts or engine tuning. Improperly matched components can lead to adverse effects.

Engine Tuning: The CKP sensor signal is a critical input for engine tuning. Experienced tuners can adjust the ECU's parameters based on the CKP sensor data to optimize ignition timing and fuel delivery for maximum power output. However, this requires specialized knowledge and equipment, and it's best left to professionals.

Disclaimer: Modifying your Xterra's engine control system can have unintended consequences, including reduced reliability, increased emissions, and potential damage to the engine. Always proceed with caution and consult with qualified professionals before making any modifications.

Conclusion

The Crankshaft Position Sensor is a vital component for your Nissan Xterra's engine management system. Understanding its function, recognizing the symptoms of a failure, and performing accurate diagnostics are crucial for maintaining your vehicle's reliability and performance. With the knowledge presented in this article, you should be well-equipped to tackle a CKP sensor issue on your Xterra with confidence. Remember to always prioritize safety and consult your repair manual for specific instructions and torque specifications.