Nissan Xterra Rear Window Replacement

The Nissan Xterra, a rugged and capable SUV, enjoys a loyal following thanks to its off-road prowess and utilitarian design. However, even the most robust vehicles are susceptible to damage, and a cracked or shattered rear window can quickly render an Xterra unusable, exposing the interior to the elements and posing a security risk. While professional replacement is always an option, understanding the process can be enlightening, and for the mechanically inclined, tackling the job yourself can be a rewarding experience. This guide provides a detailed breakdown of the rear window replacement procedure for the first-generation (2000-2004) and second-generation (2005-2015) Nissan Xterra, highlighting key differences and potential challenges.

Understanding Rear Window Construction

Before diving into the replacement process, it's crucial to understand the construction of the rear window, as this dictates the removal and installation techniques. The Xterra's rear window, typically made of tempered glass, is designed to shatter into small, relatively harmless pieces upon impact. This contrasts with laminated windshield glass, which is designed to stay intact, albeit cracked, to prevent occupant ejection. The rear window is generally bonded to the vehicle's frame using a strong adhesive, usually urethane, which creates a weather-tight seal and structural bond.

Key components involved in the rear window installation include:

- The rear window glass: Tempered glass, precisely cut to fit the Xterra's rear opening.

- Urethane adhesive: A high-strength bonding agent that secures the window to the vehicle frame.

- Primer: Applied to both the glass and the vehicle frame to promote urethane adhesion.

- Glass cleaner: Used to prepare the glass surface for primer application.

- Release agent (optional): Helps with removing trim pieces without damage.

- Molding/Trim: Decorative or functional trim that surrounds the window and enhances its appearance.

Tools and Materials Required

Successfully replacing a rear window requires the right tools and materials. Here's a comprehensive list:

- Safety Glasses and Gloves: Essential for protecting your eyes and hands from glass shards and chemicals.

- Urethane Removal Tool: A specialized tool with a cutting blade designed to slice through the urethane adhesive. This can be a cold knife, a power cutout tool, or even piano wire with handles.

- Suction Cups: Heavy-duty suction cups are used to safely lift and maneuver the old and new windows.

- Razor Blades/Scrapers: For removing residual urethane from the vehicle frame.

- Heat Gun (optional): Can soften the urethane adhesive, making it easier to cut. Use with caution to avoid damaging the paint.

- Urethane Adhesive Gun: A caulking-style gun for dispensing the urethane adhesive.

- Urethane Adhesive Cartridge: Choose a high-quality urethane adhesive specifically designed for automotive glass.

- Glass Primer: A primer designed to promote adhesion between the urethane and the glass.

- Pinchweld Primer: A primer designed to promote adhesion between the urethane and the vehicle's metal frame (pinchweld).

- Glass Cleaner: For cleaning the glass surface before applying primer.

- Shop Rags: For cleaning and wiping surfaces.

- Trim Removal Tools: Plastic pry tools designed to remove trim pieces without damaging them.

- Masking Tape: To protect surrounding paint and body panels.

- Vacuum Cleaner: To remove glass shards from the interior and exterior of the vehicle.

- Exacto knife/utility knife: For trimming urethane.

Removal Procedure

The removal process is arguably the most challenging part of the replacement. Patience and care are essential to avoid damaging the vehicle's frame or interior.

- Preparation: Start by thoroughly cleaning the area around the rear window. Cover the surrounding paint and body panels with masking tape to protect them from scratches. Protect the interior of the vehicle with a drop cloth to catch any falling glass shards.

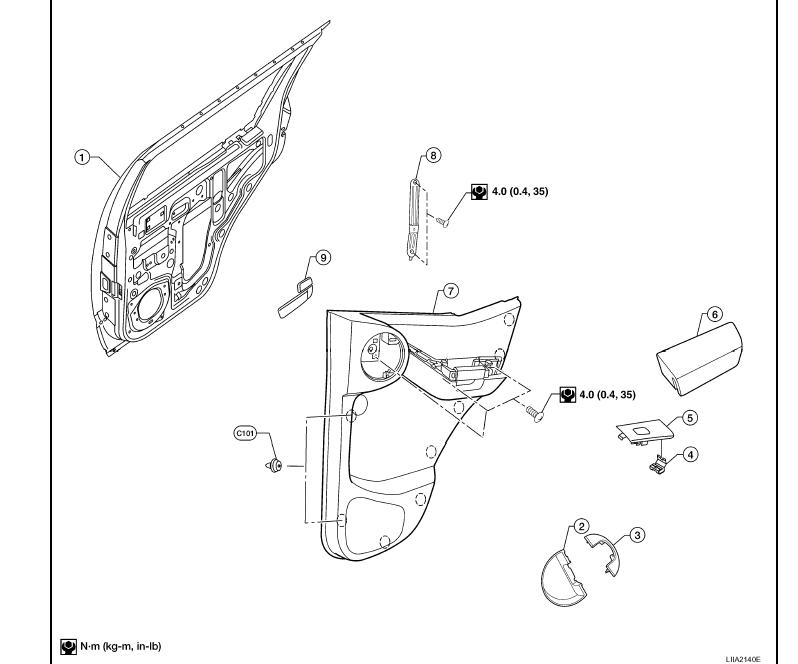

- Remove Interior Trim: Carefully remove any interior trim panels that surround the rear window. These are usually held in place by clips or screws. Use trim removal tools to avoid breaking the clips.

- Cutting the Urethane: This is the critical step. Using your chosen urethane removal tool, carefully cut through the urethane adhesive around the perimeter of the window. Work slowly and methodically, ensuring that you cut all the way through the adhesive. A heat gun can be used to soften the urethane if needed, but be careful not to overheat the surrounding paint. The 2005-2015 models have a slightly more complicated removal due to the integrated defrost lines; extra care is needed not to damage these. Piano wire is a good option in this case.

- Removing the Window: Once the urethane is completely cut, use suction cups to carefully lift the old window out of the frame. Have an assistant help you with this step, as the window can be heavy and unwieldy. Be extremely careful to avoid dropping the window, as it can shatter and create a safety hazard.

- Cleaning the Pinchweld: After removing the window, thoroughly clean the pinchweld (the metal frame around the window opening) with a razor blade or scraper. Remove all traces of old urethane and any rust or corrosion. This is crucial for ensuring a good bond with the new adhesive.

- Vacuuming: Thoroughly vacuum the interior and exterior of the vehicle to remove all glass shards.

Installation Procedure

With the old window removed and the pinchweld cleaned, you can now proceed with installing the new window.

- Test Fit: Before applying any adhesive, test fit the new window to ensure that it fits properly. Make any necessary adjustments.

- Priming: Apply pinchweld primer to the cleaned pinchweld. This promotes adhesion of the urethane and helps prevent corrosion. Allow the primer to dry completely according to the manufacturer's instructions. Apply glass primer to the perimeter of the new window where the urethane will be applied. Again, allow the primer to dry completely.

- Applying the Urethane: Load the urethane adhesive cartridge into the urethane adhesive gun. Apply a consistent bead of urethane around the perimeter of the pinchweld, following the manufacturer's recommendations for bead size and placement. Consistency is key here.

- Installing the Window: Carefully lift the new window into place using suction cups. Align the window properly and press it firmly against the urethane bead. Ensure that the window is seated correctly and that the urethane makes good contact with both the glass and the pinchweld.

- Securing the Window: Use masking tape to secure the window in place while the urethane cures. This will prevent the window from shifting or sliding during the curing process. Follow the urethane manufacturer's instructions for curing time (typically 24-48 hours).

- Reinstalling Trim: Once the urethane has cured, carefully remove the masking tape and reinstall any interior trim panels that you removed earlier.

- Leak Test: After the urethane is fully cured, perform a leak test by spraying water around the perimeter of the window. Check for any leaks inside the vehicle. If you find any leaks, you may need to apply additional urethane to seal them.

Generation-Specific Considerations

While the fundamental principles of rear window replacement remain the same across both generations of the Xterra, some specific differences warrant attention:

First Generation (2000-2004):

These models generally have a simpler rear window design without integrated defrost lines. The removal and installation process is therefore slightly less complex. However, older vehicles may exhibit more rust or corrosion around the pinchweld, requiring more thorough cleaning and preparation.

Second Generation (2005-2015):

The most significant difference lies in the integrated defrost lines embedded in the rear window.

During the removal process, extra care must be taken to avoid damaging these lines. Using piano wire is highly recommended, as it minimizes the risk of severing the delicate defrost lines. Ensure that the new window is compatible with the defrost system and that the electrical connectors are properly reattached.

Additionally, some second-generation Xterras may have more complex trim arrangements, requiring a greater understanding of trim removal techniques.

Troubleshooting and Common Issues

Even with careful preparation and execution, some issues may arise during the rear window replacement process.

- Urethane Not Adhering Properly: This is usually caused by inadequate surface preparation or using an expired or low-quality urethane adhesive. Ensure that the pinchweld and glass are thoroughly cleaned and primed, and use a reputable brand of urethane adhesive.

- Leaks: Leaks can occur if the urethane bead is not consistent or if there are gaps in the seal. Apply additional urethane to seal any leaks.

- Damaged Defrost Lines: If the defrost lines are damaged during removal, they may need to be repaired or the entire window replaced. Repair kits are available for minor damage.

- Trim Clips Breaking: Trim clips can be brittle and prone to breaking, especially on older vehicles. Have replacement clips on hand before starting the job.

- Rust or Corrosion: Significant rust or corrosion on the pinchweld may require professional repair before installing the new window.

Conclusion

Replacing a Nissan Xterra rear window is a challenging but achievable task for the dedicated DIYer. By understanding the construction of the window, using the proper tools and materials, and following the correct procedures, you can successfully restore your Xterra to its original condition. Remember to prioritize safety and take your time to ensure a professional-quality repair. When in doubt, consult with a professional auto glass technician. Not only will a pro get the job done safely, but they can also ensure that the replacement glass meets federal safety requirements.