Nx1600 Instrument Cluster Wiring And Sensor Compatibility

Understanding the intricate world of automotive instrument clusters can be daunting, especially when dealing with specific models like the NX1600. This article aims to demystify the NX1600 instrument cluster wiring and sensor compatibility, providing clear, neutral, and helpful information for anyone looking to diagnose issues, perform upgrades, or simply gain a better understanding of their vehicle's vital signs.

Decoding the NX1600 Instrument Cluster Wiring

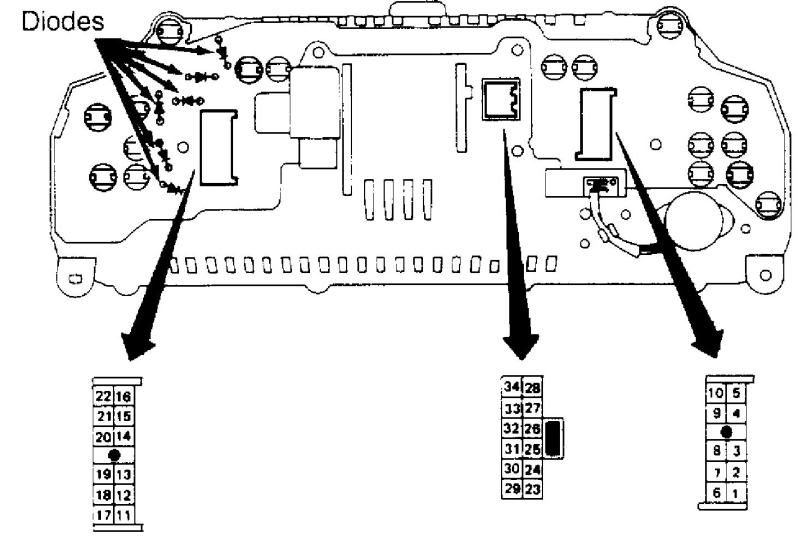

The NX1600 instrument cluster, like most modern clusters, relies on a complex network of wires to receive signals from various sensors and components throughout the vehicle. Understanding the wiring diagram is paramount for troubleshooting electrical problems and ensuring proper functionality. While specific wiring configurations can vary depending on the vehicle make and model that utilizes the NX1600, some common wires and their functions include:

- Power Supply (12V+): This wire provides the necessary voltage to power the entire instrument cluster. Its failure will render the entire cluster inoperable.

- Ground (GND): The ground wire serves as the return path for the electrical current, ensuring a complete circuit. A poor ground connection can cause erratic behavior in the instrument cluster.

- Ignition Switch Signal: This wire detects when the ignition is turned on, signaling the cluster to power up and display information.

- Backlighting Control: This wire controls the brightness of the cluster's backlighting, often connected to the vehicle's dimmer switch.

- Sensor Inputs: These wires receive signals from various sensors, such as the speed sensor, temperature sensor, fuel level sensor, and oil pressure sensor.

- Warning Light Controls: These wires activate various warning lights, such as the check engine light, oil pressure light, and low fuel light.

- Serial Communication Bus (CAN/LIN): Many modern vehicles use a serial communication bus (like CAN or LIN) to transmit data between different modules, including the instrument cluster. This reduces wiring complexity and allows for more efficient data transfer.

Common Wiring Issues and Troubleshooting Tips

Several common wiring issues can affect the NX1600 instrument cluster. These include:

- Loose Connections: Vibrations and temperature changes can cause connectors to loosen over time, leading to intermittent or complete signal loss. Always check connectors for tightness and corrosion.

- Corroded Wires: Moisture and exposure to the elements can corrode wires, increasing resistance and hindering signal transmission. Look for green or white deposits on the wires and connectors.

- Damaged Wires: Wires can be damaged by physical abrasion, heat, or rodent activity. Inspect wires for cuts, breaks, or melted insulation.

- Short Circuits: A short circuit occurs when a wire comes into contact with ground, causing excessive current flow and potentially damaging the instrument cluster or other components.

When troubleshooting wiring issues, it is crucial to:

- Consult the Wiring Diagram: Always refer to the specific wiring diagram for your vehicle to identify the correct wire colors and pin locations.

- Use a Multimeter: A multimeter can be used to test for voltage, continuity, and resistance, helping you identify broken or shorted wires.

- Check Fuses: Blown fuses can interrupt power to the instrument cluster or specific sensors.

- Inspect Connectors: Carefully inspect connectors for corrosion, loose pins, and damage. Clean corroded connectors with a contact cleaner.

NX1600 Sensor Compatibility: Ensuring Proper Functionality

The NX1600 instrument cluster relies on various sensors to provide accurate readings of crucial vehicle parameters. Ensuring that the sensors are compatible with the cluster is essential for proper functionality. Using incompatible sensors can lead to inaccurate readings, warning lights, or even damage to the instrument cluster.

Key Sensors and Their Compatibility Considerations

- Speed Sensor: The speed sensor provides information about the vehicle's speed to the instrument cluster. Compatibility depends on the sensor type (e.g., vehicle speed sensor (VSS), wheel speed sensor) and the signal type (e.g., analog, digital). Ensure the sensor outputs a signal that the NX1600 can interpret.

- Temperature Sensor: The temperature sensor measures the engine coolant temperature and transmits this information to the instrument cluster. Compatibility depends on the sensor's resistance range and its calibration curve. Using a sensor with a different resistance range will result in inaccurate temperature readings.

- Fuel Level Sensor: The fuel level sensor measures the amount of fuel remaining in the fuel tank. Compatibility depends on the sensor's resistance range and its float arm length. Using an incompatible sensor can lead to inaccurate fuel level readings and potentially cause you to run out of gas unexpectedly.

- Oil Pressure Sensor: The oil pressure sensor measures the engine oil pressure. Compatibility depends on the sensor's pressure range and its thread size. Using an incompatible sensor can lead to inaccurate oil pressure readings and potentially damage the engine due to low oil pressure.

- Tachometer Signal (RPM): Some NX1600 clusters receive a tachometer signal from the engine control unit (ECU) to display engine RPM. Compatibility depends on the signal type and voltage level.

Identifying Compatible Sensors

To ensure sensor compatibility, follow these guidelines:

- Consult the Vehicle's Service Manual: The service manual provides detailed information about the required sensor specifications.

- Check the Sensor's Part Number: The part number is a unique identifier for the sensor. Compare the part number of the replacement sensor to the original sensor's part number.

- Review Sensor Specifications: Check the sensor's voltage output, resistance range, or other relevant specifications to ensure they match the requirements of the NX1600 instrument cluster.

- Cross-Reference with Aftermarket Parts Catalogs: Aftermarket parts catalogs often provide compatibility information for various sensors and instrument clusters.

- Consult with a Qualified Mechanic: If you are unsure about sensor compatibility, consult with a qualified mechanic who has experience working with the NX1600 instrument cluster.

The Importance of Calibration

Even with compatible sensors, proper calibration is often necessary to ensure accurate readings. Some instrument clusters require calibration after replacing certain sensors. This may involve using a scan tool or diagnostic software to program the cluster to recognize the new sensor and interpret its signals correctly. Without proper calibration, the instrument cluster may display inaccurate readings, trigger warning lights, or even prevent the vehicle from starting.

NX1600 Specifics and Model Variations

It is important to acknowledge that the exact wiring and sensor compatibility for the NX1600 instrument cluster can vary significantly depending on the specific vehicle make, model, and year. Subtle differences in engine configurations, trim levels, and optional features can all impact the wiring and sensor requirements. Therefore, it is crucial to always consult the vehicle's specific service manual or wiring diagram before attempting any repairs or modifications.

Furthermore, some manufacturers may have used different versions of the NX1600 cluster across different vehicle models. These variations may have different connector pinouts, sensor compatibility requirements, and calibration procedures. Always verify that the part number of your NX1600 cluster matches the recommended part number for your vehicle.

Disclaimer: Working with automotive electrical systems can be dangerous. If you are not comfortable working with electricity, it is best to consult with a qualified mechanic. Incorrect wiring or sensor installation can damage the instrument cluster, the vehicle's electrical system, or even cause personal injury.

Conclusion

Understanding the NX1600 instrument cluster wiring and sensor compatibility is vital for diagnosing problems and ensuring the reliable operation of your vehicle. By carefully following the guidance provided in this article, consulting the vehicle's service manual, and seeking professional assistance when needed, you can confidently navigate the complexities of this essential automotive component.

Remember, safety is paramount. Always disconnect the battery before working on any electrical components and double-check your connections before powering up the system.

By taking a methodical and informed approach, you can ensure that your NX1600 instrument cluster continues to provide accurate and reliable information, keeping you informed and safe on the road.