Oil Pump Replacement Procedures And Failure Prevention

So, you're here because you suspect your oil pump might be on the fritz. That's never good news, but don't panic! An oil pump is a vital component for keeping your engine alive, but with a little knowledge and perhaps a bit of elbow grease, you can tackle this issue. This article will guide you through understanding oil pump problems, the replacement process, and how to prevent future failures. Think of me as your friendly, experienced mechanic chiming in to help.

Understanding Oil Pump Problems

First, let's confirm that your oil pump is indeed the problem. The symptoms of a failing oil pump can often mimic other engine issues, so proper diagnosis is crucial. Here are some common signs:

- Low Oil Pressure Warning Light: This is the most obvious and concerning sign. The light indicates that the oil pressure is below the safe operating range, potentially starving your engine of lubrication. Do not ignore this!

- Engine Noises: Ticking, knocking, or rattling sounds, especially from the top of the engine, can indicate insufficient lubrication. These noises often worsen as the engine warms up.

- Decreased Engine Performance: Lack of proper lubrication can lead to increased friction, resulting in reduced power and fuel economy.

- Overheating: Insufficient oil circulation can contribute to engine overheating, especially under heavy load.

- Visible Metal Shavings in Oil: If you notice metal flakes or shavings when changing your oil, it could indicate excessive wear due to oil starvation caused by a failing pump. This is a serious red flag!

Before assuming the oil pump is the culprit, rule out other possibilities like a faulty oil pressure sensor, low oil level, or a clogged oil filter. A diagnostic scan can also reveal related trouble codes.

Oil Pump Replacement: A Step-by-Step Guide

Now, let's dive into the replacement process. This is a moderate-to-difficult repair, and it's crucial to have the right tools and a good understanding of your vehicle's engine. If you're not comfortable working on your engine, it's best to leave this to a qualified mechanic.

Tools and Materials You'll Need:

- New Oil Pump (specific to your vehicle make, model, and year)

- Oil Filter

- Engine Oil (correct type and quantity for your vehicle)

- Oil Pan Gasket (or sealant, depending on your vehicle)

- Socket Set

- Wrench Set

- Torque Wrench

- Drain Pan

- Jack and Jack Stands

- Wheel Chocks

- Gloves

- Safety Glasses

- Shop Rags

- Penetrating Oil (for stubborn bolts)

- Service Manual (for your specific vehicle)

- Optional: Magnetic parts tray to keep track of small parts.

Step-by-Step Procedure:

- Safety First! Disconnect the negative battery cable. Securely chock the rear wheels and lift the front of the vehicle with a jack. Place jack stands under the frame rails and ensure the vehicle is stable before working underneath.

- Drain the Oil: Locate the oil drain plug on the oil pan and place the drain pan underneath. Carefully remove the plug and allow all the oil to drain completely. Replace the drain plug with a new crush washer and tighten to the manufacturer's specified torque.

- Remove the Oil Pan: This is where things can get tricky. Depending on your vehicle, you may need to remove other components like the exhaust system, sway bar, or engine crossmember to access the oil pan. Consult your service manual for specific instructions. Once all obstructions are cleared, carefully remove the oil pan bolts. The pan may be stuck to the engine block, so gently tap it with a rubber mallet to loosen it. Carefully lower the oil pan, being mindful of any remaining oil.

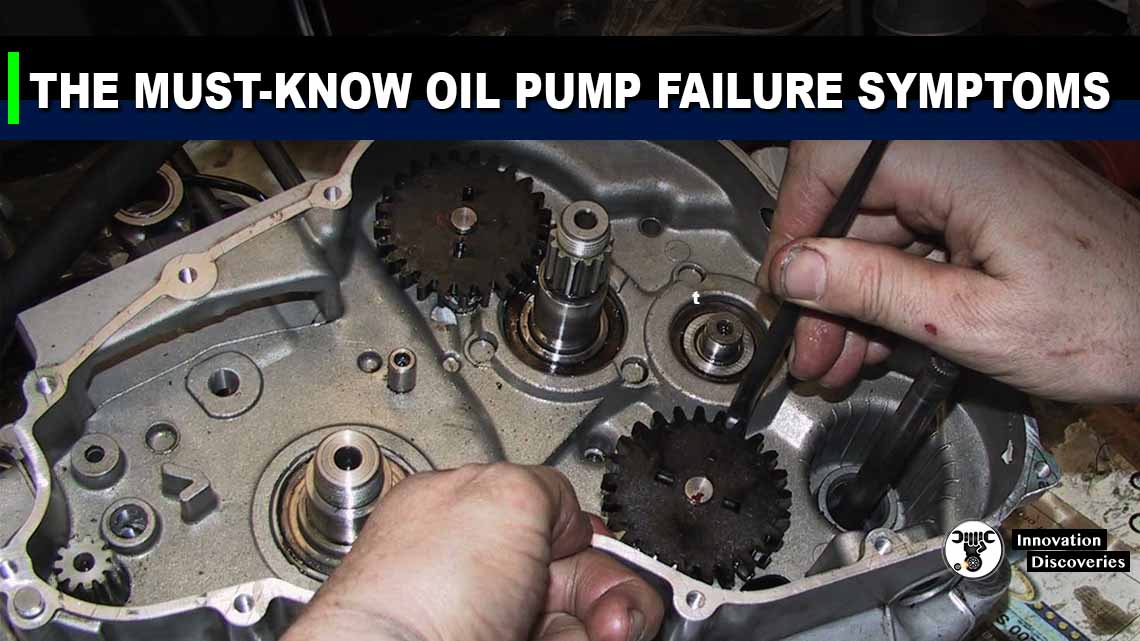

- Access the Oil Pump: With the oil pan removed, you should now have access to the oil pump. It's usually located at the bottom of the engine block, driven by the crankshaft or camshaft.

- Disconnect the Oil Pump: Carefully disconnect any electrical connectors or oil lines attached to the oil pump. Note their locations for reassembly.

- Remove the Oil Pump: Remove the bolts securing the oil pump to the engine block. The pump may be held in place by an O-ring or gasket, so gently pry it loose.

- Prepare the New Oil Pump: Lightly lubricate the new oil pump with fresh engine oil. This will help with initial lubrication during startup.

- Install the New Oil Pump: Carefully install the new oil pump, aligning it with the mounting points on the engine block. Install the bolts and tighten them to the manufacturer's specified torque.

- Reinstall Components: Reconnect any electrical connectors or oil lines you disconnected earlier. Ensure they are securely attached.

- Clean and Reinstall the Oil Pan: Thoroughly clean the oil pan and the engine block mating surfaces. Install a new oil pan gasket (or apply sealant according to the manufacturer's instructions). Carefully reinstall the oil pan, aligning it with the mounting points. Install the bolts and tighten them to the manufacturer's specified torque in a crisscross pattern to ensure even sealing.

- Reinstall Other Components: Reinstall any components you removed to access the oil pan, such as the exhaust system, sway bar, or engine crossmember. Ensure everything is properly secured.

- Install New Oil Filter: Install a new oil filter, lubricating the rubber gasket with fresh engine oil. Tighten the filter according to the manufacturer's instructions.

- Add Engine Oil: Add the correct amount and type of engine oil to the engine. Consult your vehicle's owner's manual for the recommended oil type and quantity.

- Reconnect Battery: Reconnect the negative battery cable.

- Start the Engine: Start the engine and allow it to idle for a few minutes. Check for any oil leaks around the oil pan, oil filter, and oil pump. Monitor the oil pressure gauge or warning light. The light should go out shortly after starting the engine.

- Test Drive: Take the vehicle for a short test drive, monitoring the oil pressure and engine performance. Check for any unusual noises or leaks.

Important Note: Always consult your vehicle's service manual for specific instructions and torque specifications. These instructions are general guidelines and may vary depending on your vehicle's make, model, and year.

Failure Prevention: Keeping Your Oil Pump Healthy

Replacing an oil pump is a time-consuming and potentially costly repair. Fortunately, there are several things you can do to prevent oil pump failure and keep your engine running smoothly:

- Regular Oil Changes: This is the single most important thing you can do for your engine. Dirty oil contains contaminants that can damage the oil pump and other engine components. Follow the manufacturer's recommended oil change interval and use the correct type of oil.

- Use High-Quality Oil Filters: A good oil filter will effectively remove contaminants from the oil, protecting the oil pump from damage.

- Avoid Prolonged Idling: Excessive idling can lead to oil sludging, which can clog the oil pump and reduce its efficiency.

- Address Oil Leaks Promptly: Oil leaks can lower the oil level, leading to oil starvation and oil pump failure. Repair any oil leaks as soon as they are detected.

- Warm Up Your Engine Properly: Avoid revving the engine excessively when it's cold. Allow the oil to circulate and warm up properly before putting the engine under heavy load.

- Avoid Using Oil Additives: Unless specifically recommended by the manufacturer, avoid using oil additives. Some additives can actually harm the oil pump and other engine components.

- Monitor Oil Pressure: Pay attention to the oil pressure gauge or warning light. If you notice any fluctuations or low oil pressure, have your vehicle inspected by a qualified mechanic.

Approximate Repair Costs

The cost of oil pump replacement can vary depending on the vehicle's make and model, the complexity of the repair, and the labor rates in your area. Generally, you can expect to pay anywhere from $300 to $1200 for the repair. The oil pump itself typically costs between $50 and $300, while the rest of the cost is attributed to labor and other associated parts like the oil pan gasket and oil filter.

Getting quotes from several reputable mechanics is always a good idea to ensure you're getting a fair price.

Hopefully, this article has provided you with a better understanding of oil pump problems, the replacement process, and how to prevent future failures. Remember, regular maintenance and prompt attention to any warning signs can go a long way in keeping your engine running smoothly for years to come. Good luck!