Overfender Installation And Wheel Clearance Calculations

So, you're looking to install overfenders and dial in your wheel fitment? Excellent! Overfenders are a fantastic way to achieve that aggressive, widebody look and accommodate wider wheels and tires. However, it's not just a bolt-on-and-go affair. Proper installation and, crucially, accurate wheel clearance calculations are essential to avoid rubbing, damage, and ensure safe handling. This article will guide you through the process, assuming you have a decent understanding of basic automotive tools and principles.

Understanding Overfenders and Their Purpose

Before diving into the how-to, let's recap why people install overfenders in the first place.

- Aggressive Aesthetics: This is often the primary reason. Overfenders drastically change the vehicle's appearance, adding a wider, more muscular stance.

- Accommodating Wider Wheels/Tires: This is the functional benefit. When you want to run wider wheels for increased grip and handling, overfenders provide the necessary clearance.

- Covering Existing Damage: While not ideal, overfenders can sometimes be used to cover up minor body damage around the wheel arches, saving on bodywork costs. However, addressing the underlying issue is always recommended.

There are several types of overfenders, from bolt-on kits to more involved weld-on versions. We'll be focusing primarily on bolt-on overfenders, as they are more accessible to the average DIYer. Keep in mind that even "bolt-on" kits may require some modification and trimming for a perfect fit.

Essential Tools and Materials

Having the right tools on hand will make the installation process significantly smoother and more efficient. Here's a list of what you'll likely need:

- Overfender Kit: This should include the overfenders themselves and any necessary mounting hardware (screws, bolts, etc.).

- Jack and Jack Stands: Crucial for safely lifting and supporting your vehicle. Never work under a vehicle supported only by a jack!

- Wheel Chocks: To prevent the vehicle from rolling.

- Measuring Tools: A tape measure, ruler, and potentially a digital angle finder. Precision is key for accurate calculations.

- Drill and Drill Bits: For creating mounting holes. Use a variety of bit sizes.

- Screwdrivers and Wrenches: To tighten the mounting hardware.

- Cutting Tools: This may include a rotary tool (Dremel), tin snips, or an angle grinder for trimming the overfenders or inner fender liners.

- Marking Tools: A marker or grease pencil for marking cutting lines.

- Sandpaper and Sanding Block: To smooth any rough edges after cutting.

- Body Filler (Optional): For filling small gaps or imperfections.

- Primer and Paint (Optional): To paint the overfenders to match your vehicle.

- Rust Protection: Such as primer or paint, for bare metal after cutting existing fenders.

- Safety Glasses and Gloves: Always prioritize safety when working on your car.

- Cardboard or Stiff Paper: For making templates.

Installation Steps

While the specific steps will vary depending on the overfender kit and your vehicle, here's a general outline:

1. Preparation

Jack up your vehicle and secure it on jack stands. Remove the wheels. Clean the area around the existing fenders thoroughly. This is the time to address any rust or existing damage on the fenders.

2. Test Fitting

Hold the overfender in place to get a feel for its position. This is crucial. Identify any areas where it doesn't quite fit flush against the body. Use cardboard to create templates of any complex curves or edges.

3. Trimming (If Necessary)

Many overfender kits require some trimming to fit properly. Use your cutting tools to carefully trim the overfender along the marked lines. Remember, it's better to cut too little than too much. You can always remove more material later. Smooth the edges with sandpaper after cutting.

Important: Some installations might require cutting the existing fender. This needs to be done carefully and professionally to retain structural integrity, and prevent rust.

4. Marking Mounting Holes

Once you're satisfied with the fit, use the overfender as a template to mark the locations of the mounting holes on the existing fender. Use a punch to create a small indentation at each mark. This will help prevent the drill bit from wandering.

5. Drilling Mounting Holes

Carefully drill the mounting holes using the appropriate size drill bit. Start with a smaller pilot hole and gradually increase the size. Be sure to wear safety glasses to protect your eyes from flying debris.

Pro Tip: Use masking tape around the drill area to prevent chipping the paint.

6. Installation

Attach the overfender to the existing fender using the provided mounting hardware. Tighten the screws or bolts securely, but don't overtighten them. Over-tightening can damage the overfender or the existing fender.

7. Repeat for All Overfenders

Repeat steps 2-6 for all four overfenders. Take your time and pay attention to detail.

8. Finishing Touches (Optional)

If desired, you can use body filler to fill any small gaps or imperfections around the overfenders. Sand the filler smooth and then prime and paint the overfenders to match your vehicle. Consider using flexible sealant at the top edge of the fender to avoid dirt getting trapped between the overfender and the original body.

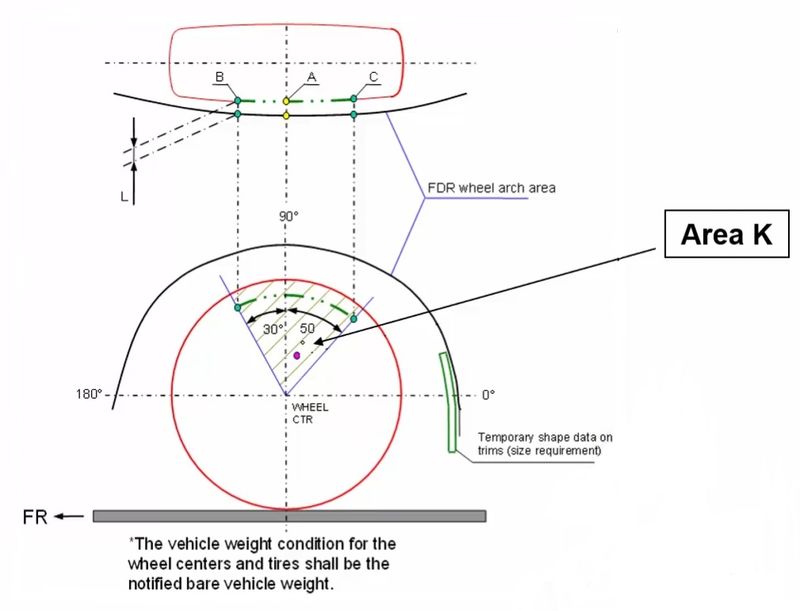

Wheel Clearance Calculations: The Math Behind the Stance

Now for the crucial part: calculating wheel clearance. Simply bolting on wider wheels without considering offset, backspacing, and tire size is a recipe for disaster. Here's what you need to understand:

Key Terms

- Wheel Width: The distance between the inner and outer flanges of the wheel, usually measured in inches.

- Offset: The distance between the wheel's mounting surface and its centerline. Measured in millimeters (mm). Positive offset means the mounting surface is closer to the outside of the wheel, while negative offset means it's closer to the inside. Zero offset means the mounting surface is exactly in the middle.

- Backspacing: The distance from the wheel's mounting surface to the rearmost edge of the wheel. Measured in inches.

- Tire Width: The width of the tire's contact patch, measured in millimeters (mm).

- Tire Aspect Ratio: The ratio of the tire's sidewall height to its width. For example, a tire with an aspect ratio of 50 means the sidewall height is 50% of the tire's width.

- Rolling Diameter: The overall diameter of the tire when inflated.

- Scrub Radius: The distance on the road surface between the steering axis and the center of the tire's contact patch. This is impacted by wheel offset and affects steering feel.

The Calculations

The goal is to determine how much wider your new wheels and tires will be compared to your stock setup and ensure they will fit within the confines of the overfenders without rubbing on the suspension components, inner fender liners, or the overfenders themselves.

- Measure Existing Wheel/Tire Setup: Start by measuring the width of your existing wheels and tires, as well as the wheel offset. This is your baseline.

- Determine Overfender Coverage: Measure how much wider the overfenders are compared to the stock fenders. This is the amount of extra space you have to work with.

- Calculate New Wheel/Tire Dimensions: Determine the width and offset of your desired new wheels. Use online tire size calculators to determine the overall diameter and width of your desired tires. Be mindful of the rolling diameter, as a significantly larger rolling diameter can cause rubbing and speedometer inaccuracies.

- Calculate the Difference: Calculate the difference in width and offset between your new and existing setups. This will tell you how much further your new wheels will stick out (or in).

Example:

Let's say your stock wheels are 17x7 with a +45mm offset. You want to run 18x9.5 wheels with a +12mm offset, and your overfenders provide an extra 50mm of coverage per side.

- The new wheels are 2.5 inches (63.5mm) wider than the stock wheels.

- The offset difference is 33mm (45mm - 12mm).

- Half of the width difference is 31.75mm (63.5mm / 2).

- Therefore, the outside edge of the new wheel will be 64.75mm (33mm + 31.75mm) further out than the stock wheel.

In this case, you'd need to ensure that the 64.75mm extension of the wheel is covered by your 50mm overfender and the tire you pick isn't too wide, causing it to protrude beyond the overfender. A smaller offset or even wider overfender might be required.

Test Fitting and Adjustments

After performing the calculations, it's still essential to test fit the new wheels and tires. Even with careful calculations, unexpected issues can arise. Check for rubbing at full lock (turning the steering wheel all the way to the left and right) and under suspension compression (bouncing the car). If rubbing occurs, you may need to adjust the ride height, roll the fenders (if applicable), or choose a different wheel/tire setup.

Remember: Always consult with a qualified professional if you're unsure about any aspect of this process. Incorrect wheel fitment can lead to serious safety issues.

By following these steps and paying close attention to detail, you can successfully install overfenders and achieve the perfect wheel fitment for your vehicle. Good luck, and happy modding!