Pop-up Headlight Mechanism Repair And Adjustment Procedure

Pop-Up Headlight Mechanism Repair And Adjustment Procedure: A Comprehensive Guide

Pop-up headlights, once a defining feature of sporty and futuristic cars from the 1960s to the early 2000s, add a distinct charm to classic vehicles. However, these mechanisms can be prone to failure, leaving you with headlights that refuse to open, close, or operate smoothly. This article provides a comprehensive guide to diagnosing, repairing, and adjusting pop-up headlight mechanisms, helping you restore your car's unique style and, more importantly, its safety.

Understanding Pop-Up Headlight Systems

Before diving into repairs, it's crucial to understand the basic components of a pop-up headlight system. Most systems rely on the following key parts:

- Headlight Motor: The heart of the system, this electric motor provides the power to raise and lower the headlights.

- Linkage Arms: These arms connect the motor to the headlight assembly, translating the motor's rotational motion into linear movement to raise and lower the light.

- Relays and Switches: These electrical components control the flow of power to the motor, activating and deactivating the headlights.

- Headlight Assembly: The complete headlight unit, including the bulb, lens, and housing.

- Limit Switches (Potentiometers): Some systems use limit switches or potentiometers to detect the position of the headlight. This ensures the motor stops at the correct open and closed positions.

Understanding how these components work together will significantly aid in troubleshooting and repairing any issues.

Common Pop-Up Headlight Problems

Several common problems can plague pop-up headlight systems:

- Headlights Don't Open or Close: This is often caused by a faulty motor, relay, or switch.

- Headlights Open/Close Slowly or Jerkily: This can indicate a worn motor, damaged linkage arms, or a lack of lubrication.

- One Headlight Works, the Other Doesn't: This points to a problem isolated to the non-functioning side, such as a motor, linkage, or wiring issue specific to that headlight.

- Headlights Open/Close Partway: This can be caused by faulty limit switches, damaged linkage, or a weak motor.

- Headlights Make Grinding Noises: This is a sign of worn gears within the motor or damaged linkage arms.

Safety First!

Before you begin any repairs, disconnect the negative terminal of your car battery. This will prevent electrical shocks and accidental activation of the headlight system while you're working on it. Always wear safety glasses to protect your eyes.

Troubleshooting and Repair Procedures

Follow these steps to diagnose and repair your pop-up headlight system:

- Visual Inspection: Start by visually inspecting all components of the headlight system. Look for broken linkage arms, corroded wiring, loose connections, and any obvious signs of damage. Check the headlight assembly itself for damage.

- Check the Fuses: Consult your car's owner's manual to locate the fuse for the headlight system. Check if the fuse is blown and replace it if necessary.

- Test the Relays: Relays are often a point of failure. You can test a relay using a multimeter. Identify the coil terminals and apply 12V. You should hear a click. Then check continuity between the switched terminals; it should change when the relay is energized. A faulty relay should be replaced.

- Test the Headlight Motor: Disconnect the wiring harness from the headlight motor. Use jumper wires connected directly to the battery to apply 12V to the motor terminals. If the motor doesn't respond, it's likely faulty and needs to be replaced. Be mindful of the polarity and consult a wiring diagram if necessary.

- Inspect the Linkage Arms: Check the linkage arms for wear, damage, or excessive play. Worn or damaged linkage arms can cause the headlights to operate erratically. Replace any damaged linkage arms.

- Lubricate the Mechanism: Apply a liberal amount of white lithium grease or a similar lubricant to all moving parts of the headlight system, including the linkage arms, gears, and hinges. This will help to reduce friction and ensure smooth operation.

- Check the Wiring and Connections: Inspect all wiring and connections for corrosion, damage, or loose connections. Clean corroded terminals with a wire brush and tighten any loose connections. Use dielectric grease on all connections to prevent future corrosion.

- Limit Switch/Potentiometer Inspection: If your system uses limit switches, use a multimeter to check for continuity and correct operation. These switches often fail and can cause erratic headlight behavior. Potentiometers can be tested by monitoring the resistance change as the headlight moves. Consult your car's service manual for specific test procedures.

Headlight Adjustment Procedure

After repairing the pop-up headlight mechanism, it's essential to adjust the headlight beam to ensure proper visibility and avoid blinding oncoming drivers. The adjustment procedure typically involves:

- Preparation: Park your car on a level surface, approximately 25 feet away from a flat wall or garage door. Ensure the car is properly loaded (fuel tank full or a representative weight in the trunk).

- Marking the Wall: Measure the height from the ground to the center of your headlights. Transfer this measurement to the wall and draw a horizontal line. Draw a vertical line directly in front of each headlight.

- Headlight Aiming: Turn on your headlights and observe the beam pattern on the wall. Most headlights are designed to have the brightest part of the beam slightly below and to the right of the center mark.

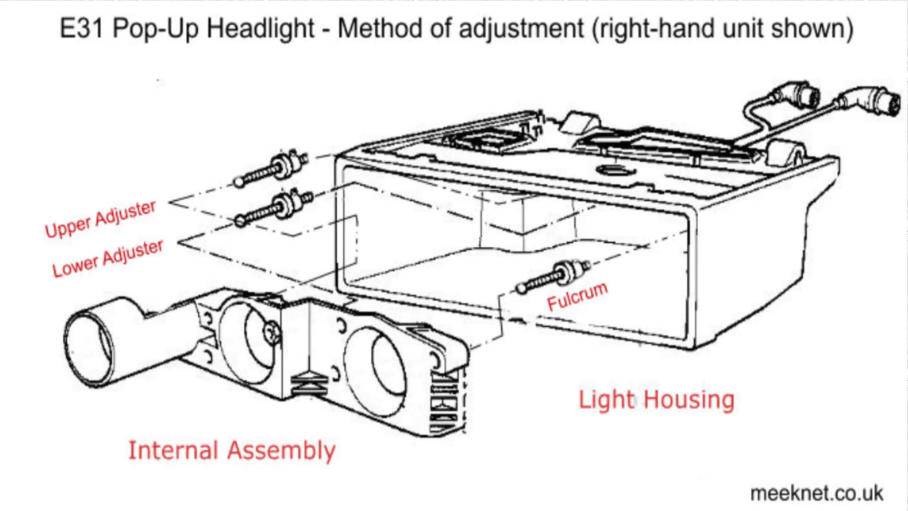

- Adjustment Screws: Locate the adjustment screws on the headlight assembly. These screws typically allow for both vertical and horizontal adjustment. Refer to your car's service manual for the exact location of the adjustment screws.

- Vertical Adjustment: Turn the vertical adjustment screw until the brightest part of the headlight beam is aligned slightly below the horizontal line on the wall.

- Horizontal Adjustment: Turn the horizontal adjustment screw until the brightest part of the headlight beam is aligned slightly to the right of the vertical line on the wall.

- Repeat for the Other Headlight: Repeat the adjustment procedure for the other headlight.

- Fine Tuning: After making the initial adjustments, drive your car at night and observe the headlight beam pattern on the road. Fine-tune the adjustments as necessary to ensure optimal visibility and avoid blinding oncoming drivers.

Note: Some modern vehicles require specialized equipment for headlight adjustment. If you are unsure about the adjustment procedure, consult a qualified mechanic.

Preventive Maintenance

To keep your pop-up headlights functioning properly, perform the following preventive maintenance:

- Regular Lubrication: Lubricate the headlight mechanism at least once a year to prevent corrosion and ensure smooth operation.

- Inspect Wiring: Regularly inspect the wiring and connections for damage or corrosion.

- Clean Headlight Lenses: Clean the headlight lenses regularly to maintain optimal visibility.

- Replace Bulbs as Needed: Replace headlight bulbs as soon as they burn out.

Conclusion

Repairing and adjusting pop-up headlights can be a rewarding experience, restoring a unique feature to your classic car. By following the steps outlined in this guide, you can diagnose and repair common problems, ensuring your headlights operate smoothly and safely. Remember to prioritize safety and consult a qualified mechanic if you are unsure about any aspect of the repair or adjustment procedure. With proper care and maintenance, your pop-up headlights will continue to shine brightly for years to come.

Disclaimer: This article provides general information and should not be considered a substitute for professional automotive advice. Always consult a qualified mechanic for specific repairs and maintenance procedures. Working on automotive systems can be dangerous. Always take necessary safety precautions.