Rb25det Swap Kit Adapter And Drivetrain Alignment

The RB25DET. A legend whispered in garages, a torque monster lurking beneath unassuming hoods. For decades, enthusiasts have been shoehorning this inline-six, twin-cam powerhouse into a myriad of chassis, trading in their underpowered incumbents for a slice of Japanese engineering brilliance. But this isn't a simple engine swap; it's a meticulous process demanding precision and a thorough understanding of drivetrain dynamics. This guide delves into the often-overlooked but absolutely critical components: the RB25DET swap kit adapter and, crucially, drivetrain alignment. We'll explore the 'why' behind these necessities, arming you with the knowledge to execute a successful and reliable swap.

Understanding the Need for an Adapter

Let's start with the basics. Unless you're incredibly lucky and your target chassis originally housed an RB-series engine (highly unlikely for most swaps), the bellhousing bolt pattern simply won't match. The transmission from your original engine is incompatible with the RB25DET. This is where the adapter plate comes in.

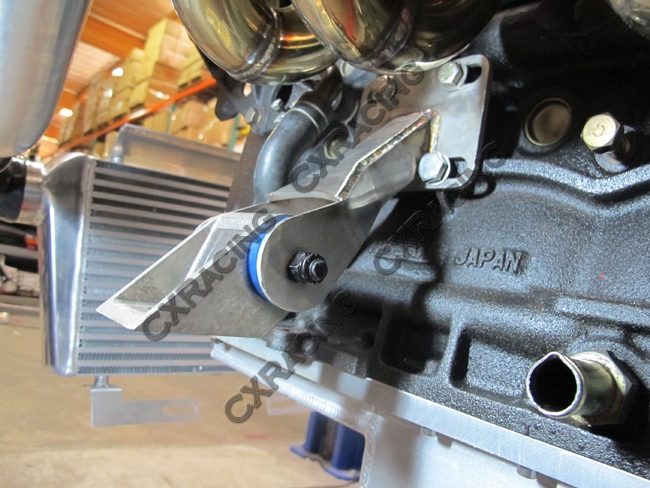

At its core, an adapter plate is a precisely machined piece of metal (typically aluminum or steel) that bridges the gap between the RB25DET's engine block and your chosen transmission. It essentially acts as a translator, converting the RB25DET's bolt pattern into one that your transmission *can* mate with. The design isn't arbitrary; several key factors dictate its geometry:

- Bolt Pattern Compatibility: This is the primary function. The adapter must flawlessly align the transmission bolt holes with corresponding threaded holes on the engine block. Any misalignment here leads to serious problems, including difficulty bolting the transmission, potential damage to the transmission input shaft, and even engine block cracking.

- Crankshaft to Transmission Input Shaft Alignment: This is perhaps the most crucial aspect. The adapter *must* maintain perfect concentricity between the crankshaft and the transmission input shaft. This ensures smooth power transfer and prevents premature wear on the input shaft bearing and clutch. Incorrect alignment leads to vibrations, difficulty shifting, and rapid component failure.

- Starter Motor Clearance: The starter motor needs to properly engage with the flywheel (or flexplate in automatic applications). The adapter must provide adequate clearance and ensure correct meshing of the starter pinion gear with the flywheel ring gear. Insufficient clearance can lead to grinding noises and starter motor failure.

- Bellhousing Depth: The adapter may need to compensate for differences in bellhousing depth between the original engine/transmission combination and the RB25DET/transmission combination. This is important for ensuring the clutch and pressure plate operate correctly (for manual transmissions) or that the torque converter is properly positioned (for automatic transmissions).

Choosing the right adapter plate is paramount. Opt for reputable manufacturers known for their precision machining and thorough engineering. Avoid generic, unbranded adapters; the potential cost savings are often outweighed by the risk of compatibility issues and drivetrain damage.

Materials Matter: Aluminum vs. Steel

Adapter plates are typically made from either aluminum or steel. Each material offers distinct advantages and disadvantages:

- Aluminum: Lighter weight, which can be beneficial for overall vehicle performance. Aluminum adapter plates are also easier to machine, potentially making them more affordable. However, aluminum is generally less strong than steel and may be more susceptible to cracking under extreme loads.

- Steel: Higher strength and durability, making it a better choice for high-horsepower applications or vehicles subjected to significant stress (e.g., racing or off-roading). Steel adapter plates are typically heavier than aluminum plates.

The best choice depends on your specific application and power goals. For most street-driven RB25DET swaps, a quality aluminum adapter is sufficient. However, for high-performance builds exceeding significant horsepower levels or those subjected to harsh conditions, a steel adapter provides an added margin of safety.

Drivetrain Alignment: The Linchpin of Reliability

While the adapter plate addresses the immediate problem of connecting the engine and transmission, it's only the first step. Achieving proper drivetrain alignment is essential for a smooth, reliable, and long-lasting swap. Drivetrain alignment refers to ensuring that the engine, transmission, driveshaft, and rear axle are all properly aligned and oriented relative to each other. Misalignment introduces stresses on drivetrain components, leading to vibration, premature wear, and potential failure.

Here's why drivetrain alignment is so critical:

- U-Joint Operation: U-joints (universal joints) are designed to operate at an angle, but excessive angles lead to increased wear and vibration. Misalignment causes the U-joints to bind and wear prematurely, reducing their lifespan and potentially leading to catastrophic failure.

- Driveshaft Balance: A balanced driveshaft is essential for smooth operation. Misalignment can throw the driveshaft out of balance, creating vibrations that are transmitted throughout the vehicle. These vibrations can damage bearings, seals, and other drivetrain components.

- Transmission Output Shaft Bearing Load: Misalignment places excessive load on the transmission output shaft bearing, accelerating wear and potentially leading to bearing failure.

- Rear Axle Bearing Load: Similar to the transmission, misalignment places undue stress on the rear axle bearings, reducing their lifespan and increasing the risk of failure.

Methods for Achieving Drivetrain Alignment

Several methods can be employed to achieve proper drivetrain alignment. The specific method depends on the vehicle and the type of modification being performed.

- Adjustable Engine Mounts: These allow for fine-tuning the engine's position, enabling you to correct for minor misalignments. This is often the simplest and most effective method for addressing slight variations.

- Adjustable Transmission Mounts: Similar to adjustable engine mounts, these allow for adjusting the transmission's position.

- Custom Driveshaft: In many RB25DET swaps, a custom driveshaft is required due to differences in length and U-joint configuration. When ordering a custom driveshaft, it's crucial to provide accurate measurements to ensure proper fitment and alignment. A driveshaft shop experienced with swaps is invaluable in this process.

- Pinion Angle Adjustment: This involves adjusting the angle of the rear axle pinion relative to the driveshaft. The goal is to maintain a specific angle between the pinion and the driveshaft, typically a few degrees. Shimming the rear axle or using adjustable control arms can achieve pinion angle adjustment.

- Measuring Angles with an Angle Finder or Digital Level: Accurately measuring the angles of the various drivetrain components is critical. An angle finder or digital level can be used to measure the driveshaft angle, transmission output shaft angle, and pinion angle. These measurements can then be compared to the recommended specifications to determine if any adjustments are needed.

Laser Alignment: For the most accurate results, especially in complex swaps, consider using laser alignment tools. These tools project a laser beam along the centerline of the drivetrain, allowing you to precisely measure and correct any misalignments. While this is a more specialized technique, it offers unparalleled accuracy and can prevent issues down the road.

Regardless of the method used, it's essential to take your time and be meticulous. Double-check all measurements and adjustments to ensure everything is properly aligned. A little extra effort during the installation process can save you a lot of headaches (and money) in the long run.

Troubleshooting Common Alignment Issues

Even with careful planning and execution, alignment issues can sometimes arise. Here are some common symptoms and potential solutions:

- Vibration: Vibration is a common symptom of drivetrain misalignment. It can be caused by excessive U-joint angles, an unbalanced driveshaft, or misalignment between the engine and transmission.

- Clunking Noises: Clunking noises, particularly when shifting gears or accelerating/decelerating, can indicate worn U-joints or excessive play in the drivetrain.

- Difficulty Shifting: Difficulty shifting gears can be caused by misalignment between the engine and transmission, which can bind the clutch or shift linkage.

- Premature U-Joint Failure: If U-joints are failing prematurely, it's a strong indication that they are operating at excessive angles due to misalignment.

If you experience any of these symptoms, it's essential to investigate the problem and identify the cause. Start by visually inspecting the U-joints and driveshaft for any signs of damage or wear. Then, use an angle finder or digital level to measure the driveshaft angle, transmission output shaft angle, and pinion angle. Compare these measurements to the recommended specifications and make any necessary adjustments. If you are unsure about how to proceed, consult a qualified mechanic or drivetrain specialist.

The RB25DET swap is a challenging but rewarding project. Understanding the importance of the adapter plate and drivetrain alignment is crucial for a successful outcome. By paying close attention to these details, you can ensure that your swap is not only powerful but also reliable and enjoyable for years to come. Remember: precision is key!