Rear End Conversion Options And Driveline Angles

So, you're thinking about changing things up with your rear end, or maybe you're chasing down a vibration that just won't quit. You've come to the right place. This isn't just about slapping in a new part; it's about understanding how all the pieces work together to keep your ride smooth and reliable. Let's dive into rear end conversion options and, more importantly, driveline angles – the often-overlooked key to a happy drivetrain.

Rear End Conversion Options: What's Right for You?

First off, let's clarify what a "rear end conversion" can mean. It's a broad term that encompasses a few different scenarios:

- Gear Ratio Change: Swapping out your ring and pinion gears for different ratios. This is typically done to improve acceleration (lower gears) or fuel economy (higher gears).

- Differential Upgrade: Moving from an open differential to a limited-slip (LSD) or locking differential. This improves traction, especially in slippery conditions or when performance driving.

- Axle Swap: Replacing the entire rear axle assembly. This is often done for strength upgrades (think going from a weaker factory axle to a beefier aftermarket option), or when changing bolt patterns for wheel compatibility. It can also be necessitated by serious damage to the existing axle.

- Independent Rear Suspension (IRS) Conversion: This is a more involved project, typically on older vehicles with solid rear axles. It offers improved handling and ride quality but requires significant fabrication and modification.

Gear Ratio Changes: Acceleration vs. Economy

Choosing the right gear ratio is a balancing act. Lower gears (numerically higher, like 4.10:1) give you quicker acceleration off the line. They are preferred by those who race or prioritize performance. Higher gears (numerically lower, like 2.73:1) prioritize fuel economy on the highway. Choosing the right ratio depends heavily on your engine's powerband, your transmission, tire size, and how you primarily use your vehicle.

Practical Tip: Use an online gear ratio calculator. Input your tire size, transmission ratios, and desired cruising speed to get a recommended gear ratio. Several calculators are available for free online; just search for "gear ratio calculator."

Approximate Cost: Changing gear ratios can range from $500 to $1500, including parts (ring and pinion, bearings, seals) and labor. The price can vary significantly based on the vehicle and the complexity of the installation.

Differential Upgrades: Traction When You Need It

An open differential allows each wheel to spin independently. This is fine for everyday driving but can be problematic when one wheel loses traction. A limited-slip or locking differential distributes power more evenly to both wheels, providing significantly better traction in slippery conditions or during hard acceleration. Common types include:

- Limited-Slip Differential (LSD): Allows some differentiation between wheel speeds but limits the amount of slip. Good for street and occasional track use.

- Locking Differential: Forces both wheels to spin at the same speed. Excellent for off-roading or drag racing, but can be harsh on the street.

- Electronic Locking Differential: Uses sensors and actuators to engage and disengage the locking mechanism based on driving conditions. Offers a good balance of performance and streetability.

Practical Tip: Research the different types of LSDs and locking differentials before making a decision. Consider the trade-offs between performance, streetability, and noise. Some locking differentials can be quite noisy during low-speed turns.

Approximate Cost: LSD or locking differential installations can cost anywhere from $800 to $2500, including parts and labor. Some units may require special tools for installation, which can add to the cost.

Axle Swaps: Strength and Compatibility

Replacing the entire rear axle assembly is a significant undertaking. Common reasons for an axle swap include:

- Upgrading to a stronger axle: For vehicles with increased horsepower or torque, upgrading to a stronger aftermarket axle can prevent breakage.

- Changing bolt patterns: To accommodate different wheels.

- Repairing irreparable damage: If the existing axle is severely damaged, replacement may be the only option.

Practical Tip: When choosing a replacement axle, ensure it's compatible with your vehicle's suspension and braking system. Also, carefully consider the overall width of the new axle, as this can affect wheel fitment.

Approximate Cost: Axle swaps can range from $1500 to $5000 or more, depending on the complexity of the installation, the cost of the new axle, and any necessary modifications.

Driveline Angles: The Key to a Vibration-Free Ride

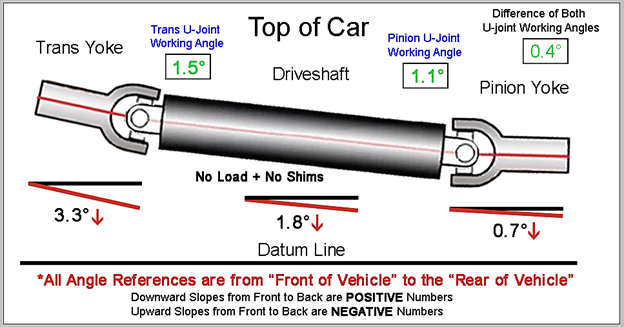

Now, let's talk about the critical, often-overlooked aspect of rear end work: driveline angles. Proper driveline angles are essential for preventing vibrations, premature U-joint wear, and even damage to your transmission and differential. When you change the ride height of your vehicle (lifting or lowering), you alter the angles between the transmission, driveshaft, and rear axle. These angles must be corrected to avoid problems.

The Goal: Ideally, the operating angles of the U-joints at the transmission and rear axle should be equal and opposite. This is referred to as U-joint cancellation. When this happens, the vibrations created by one U-joint are canceled out by the other.

Understanding Driveline Angle Terminology

- Pinion Angle: The angle of the pinion gear relative to the driveshaft.

- Transmission Angle: The angle of the transmission output shaft relative to the driveshaft.

- Driveshaft Angle: The angle of the driveshaft itself.

- Operating Angle: The angle between the driveshaft and the transmission output shaft, and the angle between the driveshaft and the pinion gear.

Measuring Driveline Angles

You'll need an angle finder (digital or bubble type) to measure driveline angles. Here's the basic procedure:

- Park on a level surface.

- Place the angle finder on the transmission output shaft flange. Record the angle.

- Place the angle finder on the driveshaft. Record the angle.

- Place the angle finder on the pinion flange. Record the angle.

Tools Needed: Angle finder, jack stands, wheel chocks, wrench set.

Correcting Driveline Angles

There are several ways to correct driveline angles, depending on the severity of the problem and the type of suspension you have.

- Shimming the Transmission: On some vehicles, you can shim the transmission mount to adjust the transmission angle.

- Adjustable Upper Control Arms: On vehicles with adjustable upper control arms (typically on 4-link suspensions), you can adjust the pinion angle by lengthening or shortening the control arms.

- Wedge Shims: These are installed between the axle and the leaf springs (on leaf-spring suspensions) to adjust the pinion angle.

- Custom Driveshaft: In some cases, a custom driveshaft with different U-joint phasing may be necessary.

Practical Tip: Don't rely solely on visual inspection to determine if your driveline angles are correct. Use an angle finder and measure the angles accurately. Even small deviations from the ideal angles can cause noticeable vibrations.

Troubleshooting Driveline Vibrations

If you're experiencing driveline vibrations, here's a systematic approach to troubleshooting:

- Check U-joints: Look for excessive play or binding in the U-joints. If they're worn, replace them.

- Check Driveshaft Balance: A bent or unbalanced driveshaft can cause severe vibrations. Have the driveshaft checked and balanced by a professional.

- Measure Driveline Angles: As described above.

- Inspect Suspension Components: Worn or damaged suspension components can contribute to driveline vibrations.

Approximate Cost: Driveline vibration diagnosis and repair can range from $100 for a simple U-joint replacement to several hundred dollars for driveshaft balancing or driveline angle correction.

Ignoring driveline angles can lead to costly repairs down the road. Taking the time to measure and correct them after a rear end conversion can save you a lot of headaches (and money) in the long run.

This information should give you a good starting point for understanding rear end conversions and the importance of driveline angles. If you're unsure about any of these procedures, it's always best to consult with a qualified mechanic. Good luck!