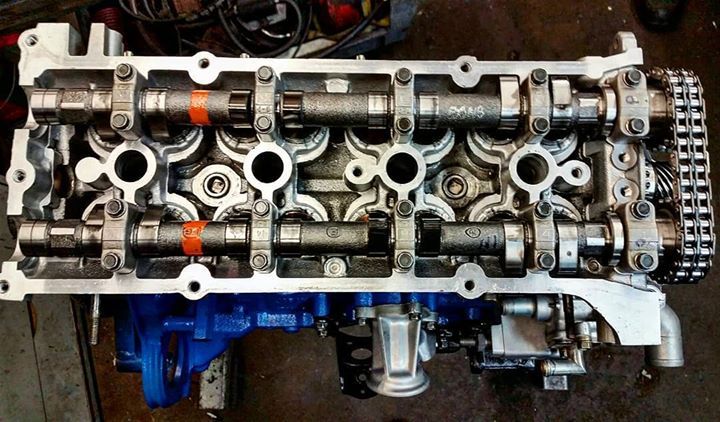

Rebuilding And Performance Upgrades For The Ka24de Cylinder Head

The KA24DE engine, a workhorse found in various Nissan vehicles like the 240SX (S13 & S14), Altima, and Frontier, is known for its reliability and potential for modification. While the bottom end is generally robust, the cylinder head can benefit significantly from rebuilding and performance upgrades. This article will guide you through the process, covering everything from identifying the need for a rebuild to selecting the right performance enhancements for your goals.

Why Rebuild Your KA24DE Cylinder Head?

Several factors can necessitate a cylinder head rebuild. These include:

- High Mileage: Over time, valve seals can harden and crack, leading to oil consumption and decreased performance. Valve guides can also wear, causing valve wobble and poor sealing.

- Overheating: Extreme heat can warp the cylinder head, causing leaks and potentially catastrophic engine damage. Signs include coolant loss, white smoke from the exhaust, and bubbling in the radiator.

- Valve Damage: Dropped valves, bent valves due to over-revving, or valves damaged by foreign objects can necessitate a rebuild.

- General Wear and Tear: Even without specific incidents, the constant stress and heat cycles can take their toll on the cylinder head components.

Recognizing the signs of a failing cylinder head is crucial. Common symptoms include:

- Loss of Power: Reduced compression can significantly impact engine performance.

- Poor Fuel Economy: Leaking valve seals can lead to increased oil consumption and reduced fuel efficiency.

- Rough Idling: Improper valve sealing can cause uneven cylinder firing and a rough idle.

- Excessive Smoke: Blue smoke indicates oil burning, often due to worn valve seals or piston rings. White smoke can indicate a coolant leak into the combustion chamber.

- Ticking Noises: Worn valve lifters or loose valve clearances can produce a ticking sound.

KA24DE Cylinder Head Rebuilding Process

Rebuilding a KA24DE cylinder head involves a series of meticulous steps. It's a task best suited for experienced mechanics or those with a solid understanding of engine components. Here's a general overview:

1. Disassembly:

Begin by carefully disassembling the cylinder head. This involves removing the camshaft(s), valve springs, retainers, valves, and valve seals. It's essential to keep track of the location of each component to ensure proper reassembly. Labeling is highly recommended.

2. Cleaning:

Thoroughly clean all components using a parts washer and appropriate solvents. Remove any carbon deposits, oil residue, and debris. Pay particular attention to the valve guides and valve seats.

3. Inspection:

This is arguably the most critical step. Carefully inspect each component for wear, damage, or cracks. Key areas to examine include:

- Cylinder Head Surface: Check for warping or cracks. Use a straight edge and feeler gauge to measure flatness.

- Valve Guides: Measure the valve guide clearance. Excessive clearance indicates wear and the need for replacement.

- Valve Seats: Inspect the valve seats for pitting, wear, or cracks.

- Valves: Check the valve faces for wear, burning, or cracks. Measure the valve stem diameter and compare it to specifications.

- Valve Springs: Measure the valve spring free length and spring rate. Weak or broken springs should be replaced.

- Camshaft(s): Inspect the cam lobes for wear or damage.

4. Machining and Component Replacement:

Based on the inspection, determine which components need to be replaced or machined. Common machining operations include:

- Cylinder Head Resurfacing: To correct warping and ensure a proper seal with the engine block.

- Valve Seat Grinding or Cutting: To restore the valve seat angle and ensure proper valve sealing.

- Valve Guide Replacement: If the valve guide clearance is excessive.

- Valve Refacing: To remove minor imperfections from the valve face.

New components often used in a KA24DE cylinder head rebuild include:

- Valve Seals: To prevent oil leakage into the combustion chamber. Consider upgrading to Viton valve seals for increased heat resistance.

- Valve Springs: To maintain proper valve control and prevent valve float.

- Valves: If the existing valves are damaged or excessively worn.

- Valve Guides: If the valve guide clearance is excessive.

- Head Gasket: A new head gasket is essential for a proper seal between the cylinder head and engine block.

5. Reassembly:

Carefully reassemble the cylinder head, following the manufacturer's specifications for torque values and procedures. Ensure that all components are properly lubricated during reassembly.

6. Valve Adjustment:

After reassembly, adjust the valve clearances to the specified values. This is crucial for proper engine operation and performance.

KA24DE Cylinder Head Performance Upgrades

Once you're rebuilding your KA24DE cylinder head, it's an excellent opportunity to consider performance upgrades. These upgrades can improve airflow, increase horsepower, and enhance overall engine performance. Here are some popular options:

1. Porting and Polishing:

Porting involves modifying the intake and exhaust ports to increase airflow. Polishing smooths the port surfaces to reduce friction and further improve airflow. This is a labor-intensive process that requires skill and precision, but it can yield significant performance gains. CNC porting offers consistent and repeatable results.

2. Upgraded Valves:

Installing larger valves or valves made from higher-quality materials (e.g., stainless steel) can improve airflow and increase the engine's ability to breathe at higher RPMs. Consider using valves with a swirl-polished finish for optimal performance. Back-cut valves can also improve flow.

3. Upgraded Valve Springs and Retainers:

Higher-performance camshafts often require stiffer valve springs to prevent valve float at high RPMs. Upgraded retainers (e.g., titanium retainers) can reduce valve train weight and improve responsiveness. Chromoly retainers are a good option for a balance of strength and weight.

4. Performance Camshafts:

A performance camshaft is one of the most effective upgrades for increasing horsepower. Camshafts with different lobe profiles can alter the engine's power band, providing more power at specific RPM ranges. Choose a camshaft that matches your driving style and performance goals. Be sure to consider the valve spring requirements of the chosen camshaft.

5. Adjustable Cam Gears:

Adjustable cam gears allow you to fine-tune the camshaft timing to optimize engine performance. This is particularly useful when using a performance camshaft or after cylinder head resurfacing. Adjusting cam timing can improve low-end torque or high-end horsepower, depending on the application.

6. Upgraded Rocker Arms:

While often overlooked, upgrading rocker arms, especially in high-performance applications, can significantly improve valve train stability and reduce friction. Roller rocker arms are a popular choice for smoother operation and increased durability.

Considerations Before Upgrading

Before embarking on any performance upgrades, consider the following:

- Budget: Performance upgrades can be expensive. Set a realistic budget and prioritize the upgrades that will provide the most significant performance gains.

- Engine Condition: Ensure the rest of your engine is in good condition before investing in cylinder head upgrades. Upgrading the cylinder head without addressing other potential issues may not yield the desired results.

- Driving Style: Choose upgrades that are appropriate for your driving style and intended use of the vehicle. A camshaft designed for high-RPM performance may not be ideal for daily driving.

- Professional Installation: Some upgrades, such as porting and polishing, require specialized skills and equipment. Consider having these upgrades performed by a qualified professional.

- Tuning: After installing performance upgrades, it's often necessary to have the engine tuned to optimize performance. This may involve adjusting the fuel and ignition maps in the engine control unit (ECU).

- Compatibility: Ensure that all components are compatible with each other and with your existing engine setup.

Conclusion

Rebuilding and upgrading your KA24DE cylinder head can significantly improve engine performance and reliability. Whether you're addressing a worn cylinder head or seeking to unlock more power, understanding the process and choosing the right upgrades is crucial. By following the steps outlined in this article and considering the factors discussed, you can ensure a successful rebuild and achieve your performance goals. Remember to consult with experienced mechanics and tuners for personalized advice and guidance. Proper research and planning are essential for a successful KA24DE cylinder head project.